|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Webley & Scott Automatic Pistols by Ed Buffaloe

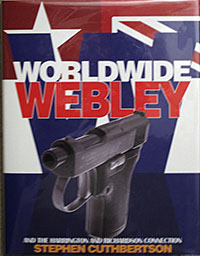

At this writing, there are two primary sources for information on the Webley & Scott auto pistols: Gordon Bruce’s Webley & Scott Automatic Pistols, and Stephen Cuthbertson’s Worldwide Webley and the Harrington and Richardson Connection. To the best of my knowledge, Webley & Scott never referred to any of their guns using a production date as a model number. Prior to Dowell’s book, model numbers may not have been assigned to many of the pistols. Dowell, Bruce, and Cuthbertson do not always agree on model nomenclature, but from them we at least have starting points for sorting the various guns. Bruce’s book is arranged by order of production, as much as is feasible, whereas Cuthbertson’s book is ordered by caliber, making it somewhat easier to find information on a particular gun, but more difficult to get a sense of the chronology of the guns. I have chosen chronological ordering. I have tried to include detailed information on the more common guns, but have necessarily had to limit the information I can provide on experimental pistols. For complete information on all models, please consult one or both of these excellent books. Any errors in the data provided here are almost certainly my own.

According to Gordon Bruce the Webley & Scott company was largely idle in 1903 due to the end of the Boer war the previous year and the subsequent expiration of the company’s contracts with the British War Office. In the Spring of that same year Whiting was promoted to the company Board of Directors and was given carte blanche to develop a much-needed new product. The mostly idle manufacturing facilities of the company were placed at Whiting’s disposal. Model 1903 Experimental Pistol

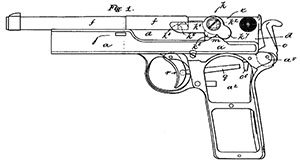

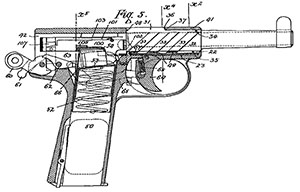

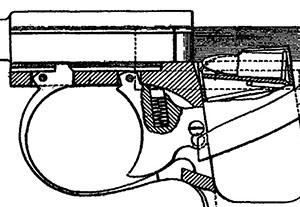

Whiting filed three patents in 1904 (British patents 1904-3820, 1904-17856, and 1904-25028), each a further elaboration of the same design. The new gun featured a locked-breech, with a falling-block locking mechanism, a recoil buffer, and a v-shaped recoil spring and lever under the right

Lugs at each end of the detachable trigger guard lock into

A flat area is milled in the top right-hand corner of the slide, the forward portion of which forms an opening over the rear of the barrel to serve as the ejection port for the gun. The rear portion of the flat houses the bottle-neck spring steel extractor.

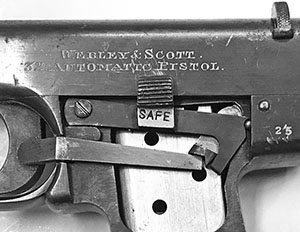

The magazine holds eight cartridges. The finish is carbon blue with a nickeled magazine. The transfer bar is fire blued. The gun is relatively simple, with only 35 parts total. It originally sold for 42 shillings, which was half the price of the 1903 Colt, which sold for 85. The Model 1900 Browning sold for 65 shillings. The wholesale price for the Webley was only 28 shillings in 1906. This pricing information was taken from Gordon Bruce’s excellent book Webley & Scott Automatic Pistols, page 109. The earliest pistols are hand-engraved on the left side of the slide in all-capital serif characters: WEBLEY & SCOTT LTD. The Webley & Scott winged bullet logo is also engraved above the trigger guard at the front of the slide. A second inscription has also been observed, as follows: WEBLEY & SCOTT Later examples are roll-stamped in all-capital sans-serif characters, originally at the rear of the slide on early pistols and at the front on very late pistols: WEBLEY & SCOTT LTD. The Webley & Scott winged bullet logo may be seen stamped either at the front or rear of the slide, opposite the inscription. Also observed is the following inscription: WEBLEY & SCOTT LTD. Very early guns, up to at least serial number 16, have their serial number stamped on the right side of the frame, just in front of the hammer. By serial number 25, it had been moved to the same position on the left side of the frame. The serial number, or the last three digits thereof, is also stamped on the bottom of the barrel and slide. The last two digits of the serial number are stamped on many small parts. The barrel, at least on early guns, is stamped on the left side with the caliber.

The wide round-head hammer is drilled through and milled in an inverted cone shape with circular grooves. The earliest hammers are checkered on their upper surface, as are the early hammer safeties, but the majority of hammers have lateral triangular-cut serrations across the upper surface, as do most safeties. The slide is not serrated, but the checkered rear sight extends out slightly on either side and can be used to retract the slide. The rear sight also serves to retain the firing pin in the breech block. The firing pin is made of phosphor bronze. The magazine is held in place by a spring-loaded lever at its base, which is squeezed toward the front of the grip to release the magazine. This follows the pattern set by the Model 1899/1900 Browning. The length of the (internal) magazine release lever was reduced by about 5mm sometime around mid-1906 (possibly after only 100 or so pistols were manufactured), so that the earliest magazines do not work in later guns, and vice-versa. Some early magazines were modified to work in later guns with the shorter release lever. The original design underwent considerable modification over the next three years, as Whiting corrected minor problems, simplified production, and sought to make the gun more marketable. Hence, multiple variants were produced, making them highly collectible. Later pistols modified from the original pattern are sometimes referred to as Model 1906 or 1907 pistols by collectors, or as “transitional,” which is how both Bruce and Cuthbertson designate them. Model 1905 Variations - Transitional Pistols

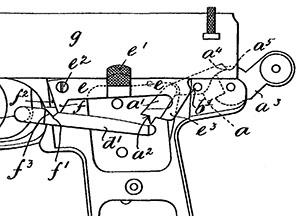

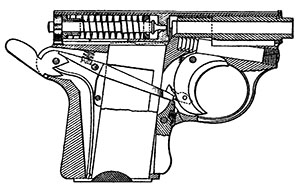

The first issue addressed was the safety. The original rather primitive hammer safety puts the hammer in a half-cock position, so the gun has to be manually cocked from its safe position to fire. Whiting also developed a lever safety, above the grip on the left side of the gun, that simply serves to move the transfer bar down so that it no longer connects with the sear. It does not lock the sear or the hammer. Serial number 6 is said to have the lever safety, as do serial numbers 636, 1000, 1207, 1737, 3083 , 3171, and 3317, whereas serial numbers 16, 69, 114, 292, 1212, 1390, 2125, and 4101 have the hammer safety. An alternative safety was designed within six months of the start of production, consisting of a horizontal lever beneath the left grip that pivots from the front. A serrated rectangular button in the middle of the lever is set into a notch in the top of the left grip plate. When the button is pushed up the word SAFE appears in the grip plate notch beneath the button, indicating that the safety is engaged. When engaged, the rear of the safety lever moves upward to lock the sear and the hammer, while a projection at the forward end presses the transfer bar down and out of engagement with the sear, and a lug just behind the button fits into a notch in the slide to lock it in place. Additionally, there is a stud projecting from the back of the safety lever into the frame.

On 1 May 1907 John Carter and Frank T. Murray of the Webley & Scott company filed a second patent for an improved safety mechanism. Patent number 10,104 was granted on 3 October 1907. It adds another small lever known as the “rocker pivot” between the horizontal safety bar and the transfer bar. When the safety is engaged the front portion of the safety lever presses the rocker pivot down, moving the transfer bar out of alignment with the sear. But the rocker pivot has a second function: when the trigger guard is pulled down to disassemble the gun, the recoil lever engages the rocker pivot and also causes it to move the transfer bar out of alignment with the sear, preventing the hammer from being released during disassembly. A spring and plunger assembly at the rear of the gun tensions the safety bar, holding it in either the on or off position. To sum up, this safety mechanism not only disconnects the transfer bar from the sear, but also locks the sear and hammer when the hammer is cocked, while additionally disconnecting the transfer bar when the trigger guard is removed, and also locks the slide open and disconnects the transfer bar after the last round is fired. Cuthbertson states that the majority of guns with the button safety fall in the serial number range between 3500 to 4909, though serial number 25 also has one. It is likely that this early serial number was retrofitted with the later design, since the rocker pivot was not patented until 1907; additionally, this serial number remained in the Webley & Scott collection until 1955. By the end of the first year of production it became obvious that the removable trigger guard was rather more easily misplaced than anyone had imagined and, since it held the barrel in place, without it the gun was totally inoperative. Some users also tended to try to re-insert it backward. John Carter and Frank T. Murray filed a patent for a mechanism to retain the trigger guard on 22 January 1907 and were granted British patent number 1907-1601 on 20 June 1907. Gordon Bruce shows a gun (serial number 4736) with this mechanism installed. However, clearly the mechanism was too complex and too expensive to manufacture, as it was never adopted. Instead, a simple pin was installed on the back of the trigger, or a hook or shoulder was added to the rear of the trigger guard, to prevent its being separated from the rest of the gun.

The early bottle-shaped extractor is made of spring steel. During 1907 the extractor is shortened from 1.75 inch to 1 inch, and the milled area on the right corner of the slide is eliminated. The new shorter extractor is machined from stock and requires a coil spring to tension it. The short extractor begins to appear around serial number 4900 (according to Cuthbertson), but does not become standard equipment until after serial number 5000. The width of the hammer is reduced from 10 mm to 7 mm around serial number 7000. Later still, the succeedingly smaller and deeper circular grooves in the hammer are eliminated. The new hammer has flat sides with a hole drilled through the round head. Near the end of production, the rear sight is eliminated and replaced with a groove milled in the top of the slide. The front sight is shortened accordingly. The contour of the slide above the trigger guard is changed to simplify machining. The new slide has 17 triangular-cut serrations at the rear. The firing pin on guns with no rear sight is retained with a transverse pin.

The Model 1906 Experimental .45 Caliber

Like other early Webley & Scott pistols,

An internal slide stop lever on the left side of the gun has a small projection that is lifted by the rear of the magazine follower when the magazine is empty in order to lock the slide open. The same small projection serves as the ejector. The slide stop lever, when lifted by the magazine follower, also lifts an external button at the left rear of the grip frame. This button, when pressed down, releases the slide stop lever, and can also serve to lock the slide open manually. The gun has a transfer bar on the left side, connected to the trigger at the front and reaching to the sear at the rear. A disconnector consisting of a vertical bar on the left side is depressed when the barrel drops under recoil, forcing the transfer bar out of connection with the sear and preventing multiple shots from being fired. The transfer bar and disconnector are covered by a small housing behind the trigger, extending under the left grip plate. A hammer safety, identical to that on the Model 1905 .32 auto pistol, forces the hammer into a half-cock position when applied, and automatically disengages when the hammer is manually cocked. The slide inscription, likely hand engraved, is on the left side in all-capital italic serif characters as follows: WEBLEY & SCOTT LTD. The Webley & Scott winged bullet logo is in front of the slide inscription. The serial number is stamped on the left side of the frame behind the trigger, and on the top of the slide and barrel. This gun may have been intended for submission to the U.S. Ordnance Board tests which had been

scheduled to begin in September of 1906, but which were eventually carried out in January of 1907. Whiting is known to have visited the U.S. in 1905 and was probably made aware at that time of

the development of the .45 Automatic Model 1906 cartridge. But the gun was never submitted for

testing, despite the inscription “Patent applied for in U.S.A.” I have designated it an experimental

design. Roy G. Goodman, in his 1962 article on the Webley & Scott .455 pistols avers that the Model 1906 is actually in .455 caliber, and Dowell also states the same. Cuthbertson clarifies the

issue by stating that probably only three prototype guns were made in .45 caliber, but that three years later the Small Arms Committee of the British War Department tested a modified version of

this same pistol chambered in .455 Webley & Scott Automatic Model 1904, but the modifications were extensive enough (an internal hammer plus other changes) that the gun is considered

separately (see below: 1909-1912 Test Pistols).

The Browning 6.35 mm cartridge was designed in the U.S. in the period 1903-1904, but was first manufactured commercially in Belgium in 1906. The cartridge (and the FN Browning pistol it was designed for) was an instant success. Arms manufacturers throughout Europe began to design small self-loading pistols to shoot the new cartridge. Diminutive auto pistols became a “craze,” and Webley & Scott sought to claim a piece of the market for themselves. When this cartridge was

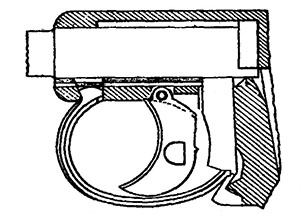

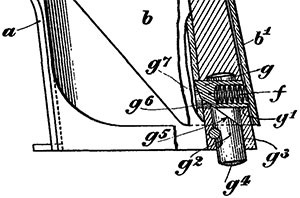

As early as 22 December 1906, John Carter and John Townsend Murray of Webley & Scott filed a patent for a gun that appears to have been intended to fire the 6.35 mm Browning Cartridge. The gun was of an innovative design, with the recoil spring surrounding the striker, a front-mounted grip safety, and a barrel held in place by an angled screw beneath it. British patent number 1906-29,221 was granted on 28 November 1907. But this gun was never manufactured. Instead, William Whiting miniaturized his existing .32 caliber design, with several innovations inspired

Whiting chose to use only the front locking lug to retain the barrel of the 6.35 mm pistol; the lug pivots into position when the trigger guard is locked in place. The rear of the trigger guard has a small hook and is designed in such a way that it appears contiguous with the frame. The exact design may have never been patented, but is clearly shown in a 1908 patent drawing that covers the design of the frame and slide for a top -ejecting pistol. The new pivoting trigger guard continues to be made of tempered spring steel, but no longer serves as a recoil buffer. Gordon Bruce comments that the new trigger guard design also “required fewer machining operations in its construction than the previous form, thus making the weapon far more economical to produce.”

Like the Model 1905 .32 caliber,

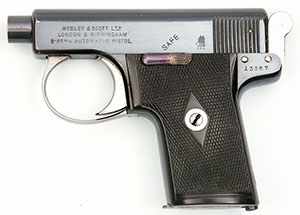

The hammer is flat, unadorned, and has no hole drilled through the head. There are 12 triangular -cut serrations at the rear of the slide on both sides. Early Model 1907 pistols are quite scarce. Serial number 10731 (shown in Cuthbertson) has the winged bullet logo at the very front of the slide, on the left slide, with the slide inscription immediately behind it, but on serial number 13367 the Webley & Scott winged bullet logo is at the rear of the slide, just in front of the serrations. The slide inscription is in all-capital sans-serif characters at the front of the slide, as follows: WEBLEY & SCOTT LTD. The serial number is on the left side of the frame in front of and beneath the hammer, and may also be found stamped on the back of the grip strap of some examples. The last three digits of the serial number are also stamped on the bottom of the slide and barrel. The grip plates are of hardened rubber and the grip-frame cutouts beneath them are rectangular, with rounded corners. The magazine holds six cartridges. The Model 1907 was about two ounces lighter than the 1906 FN Browning, and eight ounces lighter than the Webley & Scott Model 1905 in .32 caliber. According to Gordon Bruce, production began “prior” to May 1907. Cuthbertson says, “[b]y late 1907, fourteen prototype pistols...had been assembled. Serial numbers are in the same series as the .32 caliber pistol. According to Gordon Bruce, the earliest 6.35mm serial number manufactured was 7060, and the first eight pistols were in the range 7060-7067, followed by 7078-7083, 10000 -11099, and finally 13000-13799 approximately. According to Cuthbertson, only about 2100 of the Model 1907 were manufactured.*

Webley & Scott Automatic Pistols: Part 2 (1908-1911) * Please contact me if you have information about, or can provide photographs of, Webley & Scott automatic pistols discussed in this article: edbuffaloe@unblinkingeye.com. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2019 by Ed Buffaloe. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Remove the magazine and make sure the

chamber is empty.

Remove the magazine and make sure the

chamber is empty.