|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Webley & Scott Automatic Pistols by Ed Buffaloe The Model 1912 6.35mm “Hammerless” Competition in the vest pocket pistol market was quite intense in the second decade of the 20th century, and Webley & Scott thought a “hammerless” model might sell better than their already existing external hammer model. As it turns out, that wasn’t necessarily true, as it was well after the First World War before sales of the hammerless model began to exceed those of the M1908 standard hammer model.

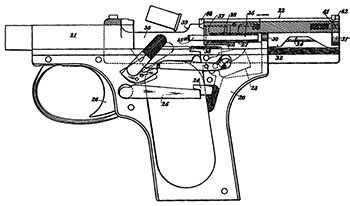

The Model 1912 features an internal

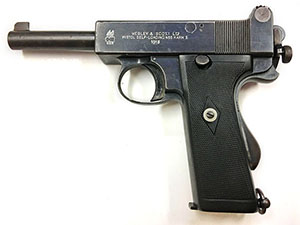

The lockwork and other components of the Model 1912 are nearly identical to the 6.35mm standard hammer model of 1908, with the exception that the magazine does not have an ejector on its lip, and unlike earlier guns the bottom-mounted magazine release is positioned toward the right side of the grip frame and the hole in back of the magazine is centered to forcibly remind the user that magazines are not interchangeable between the two 6.35mm models. The grip plates are held by two screws each, the lower screws being longer than the upper because they are also used to retain the magazine release mechanism, instead of a pin. The slide inscription is identical to earlier 6.35mm pistols, in all-capital sans-serif characters at the front of the slide, as follows: WEBLEY & SCOTT LTD. The Webley & Scott winged bullet logo is just in front of the slide serrations. Grip plates are of checkered vulcanite (also known as hard rubber), and are perfectly flat on the bottom. Checkered walnut grip plates were available as an option, but are quite scarce today.

Sometime in 1914 it was determined that an interior redesign was necessary to correct a problem that had become apparent with the early guns. If a recoil spring should break, the guide rods were short enough that they would come out of their track and lock up the gun, making disassembly almost impossible. So the springs and guide rods were both lengthened, and the breech block was redesigned to allow longer tunnels for the recoil springs and guide rods to fit into. The rear plate was also shaped somewhat differently on the new variant. By the time the interior redesign was completed World War I had started, and production of the Model 1912 was halted until 1919, after the war had ended. So there were a few rare guns, made just before the war, with 8 slide serrations and the new trigger, but with the old rear plate and the short breech block and short springs and guide rods inside. But the majority of late variant guns with 8 slide serrations also feature the extended guide rods and springs. After the war the serial number was moved from the left grip tang to the rear grip strap. In 1924 and 1925 a few guns were made with short barrels that did not extend past the front of the slide--these are quite rare and collectible. According to Cuthbertson, total production was 14,987 pistols; the highest serial number he had recorded was 161859, made in 1938.

The Mark I .455 Caliber of 1912

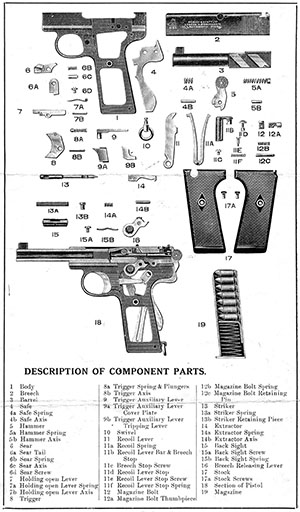

Minor changes were made to the transfer bar and sear before commercial production began in earnest, and the lanyard was moved from the base of the grip to the rear of the grip. Otherwise, there were no major innovations. The V-shaped mainspring under the right grip plate has no roller and is no longer pinned at the bottom but floats freely under the grip plate. The mechanism of the grip safety was changed slightly--the grip safety still moves the sear forward, but when the

Like the 9mm Model of 1909, the disconnector sits behind the trigger and is depressed by the recoiling slide; it moves the transfer bar down just enough that if the trigger is engaged the transfer bar cannot reach the sear. The left side slide inscription includes the year of production, and is in all-capital sans-serif characters, as follows: WEBLEY & SCOTT LTD.

WEBLEY & SCOTT LTD. The winged bullet logo was at the front of the slide on the left side. Navy contract pistols were stamped with an upper-case N after Mark I: WEBLEY & SCOTT LTD. On military pistols, the serial number is stamped on the bottom of the frame just in front of the trigger guard. Commercial pistols have the serial number on the grip tang, just in front of the hammer. According to Cuthbertson, 426 pistols in .455 caliber were offered for retail sale in 1913. An additional 393 were offered in 1914, commercial production having been cut short by the advent of the Great War. Commercial production did not begin again until May of 1919. 222 pistols were made in 1919, and another 100 in 1923. Less than 100 were made between 1924 and 1933, when production ended. In total, the admiralty purchased 7530 Webley & Scott Mark I pistols in .455 caliber, and another 1260 were made and sold commercially.

The Mark I .455 Caliber “Royal Horse Artillery” Model

Nonetheless, Webley & Scott delivered a further 50 auto pistols for army testing in 1913, all fitted with adjustable rear sights, and about half with shoulder stocks. The pistols were eventually accepted for use by the army during World War I, and were also sold commercially. Webley & Scott never ceased referring to them as the Royal Horse Artillery pattern pistol, although they were never so marked. Gordon Bruce covers these

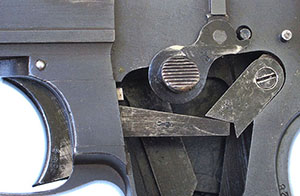

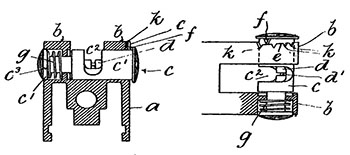

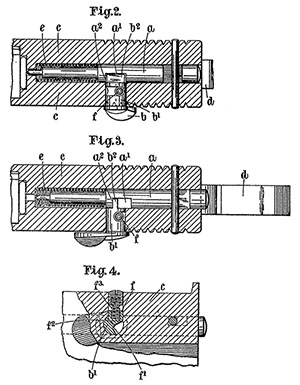

The adjustable rear sight was patented by William Whiting in January of 1912 (British patent 1912-201). The army wanted at least the possibility of shooting the gun at targets out to 200 yards, though testing eventually proved that the gun was not very accurate beyond 150 yards. Additionally, the army had never been satisfied with the safety mechanisms on the early .455 test pistols. They wanted to be able to carry the pistol safely with a cartridge in the chamber, so William Whiting also designed another hammer-safety which he patented in May of 1912 (British patent 1912-11418).

These guns bear markings identical to the regular production Mark I .455 pistols, including the year of manufacture. Another variant is marked “Mark I No. 2” and appears as follows: WEBLEY & SCOTT LTD. By Cuthbertson’s account, only 489 were made, making this one of the most collectible of W&S pistols.

The problem was that the Model 1908 had never been drop-safe because the manual safety lever designed by William Whiting simply moved the transfer bar away from the sear, but did nothing to lock either the hammer or the firing pin. Whiting had given preference to his own design over the much better, safer design of John Carter and Company Director Frank T. Murray back in 1906 (see British patent 1906-24382), possibly because it was much cheaper to manufacture. So far as we know no one was ever killed accidentally due to the safety, but the military insisted they would not buy the standard Model 1908 in .32 caliber unless the safety issue were addressed. William Whiting retired in July of 1920 and the man who filled his shoes was John William Fearn. According to Gordon Bruce, “Fearn became Works Manager and was then Technical Adviser to the company.” The army’s director of artillery informed the company of its safety requirement in a letter dated 9 February 1921, and on 16 March 1921 Works Manager Fearn and

In the design shown in the patent, the safety is engaged when the lever points down and is disengaged when the lever is turned parallel with the slide. The first thing that the military asked for was that this functionality be reversed. They also stated a preference for an ambidextrous safety and complained that the bottom-mounted magazine release was too easily depressed. It was also suggested that the angle of the grip to the frame be increased slightly. Reversing the functionality of the safety lever was simple, but Webley & Scott deemed an ambidextrous safety and any change to the magazine release or grip frame too costly to undertake without a sizable contract to justify the cost of retooling; the military were unable to guarantee future purchases, and ultimately never did make purchases in any great quantity. The Improved Model was tested against the 1903 Colt .32 by the British Small Arms Committee late in 1922, the report of their tests being dated 31 January 1923. While the committee was careful to note every advantage of the Webley over the Colt (particularly the longer grip frame, the lighter weight, and the slide that remained open when the last round was fired), they nonetheless “reluctantly,” according to Cuthbertson, reported the Colt to be more accurate and more reliable. Neither gun was ultimately accepted by the War Office. The original patent showed the new safety lever being tensioned from above by a spring and plunger (see Fig. 4 of the patent drawing), but the actual implementation of the safety uses a pin and screw inserted from the rear, to the left of the firing pin. Because the center of the firing pin had to be cut away to allow the safety lever to function, the firing pin was made of steel rather than the bronze that was used on earlier pistols. All Model 1921 .32 caliber pistols were modified standard models, with the engraved word SAFE milled away from the left side. Some retained the old grip plates with the cutout on the left plate for

Field stripping remains the same as for the 1908 standard model, though the slide on the improved model can be removed whether or not the safety is engaged.

As stated above (in the section on the 32 Caliber Improved Model), the earliest two prototypes for this pistol were made in July 1920, about the time of the departure of William Whiting. Gun sales cratered after World War I, and the British economy was saddled with considerable debt that limited further government spending. Large wartime firearms contracts were a thing of the past, and Webley & Scott needed to seek new markets overseas. So the first thought of Managing Director Frank T. Murray and Works Manager John William Fearn was to see if it might be feasible to update an existing military pistol.

An additional prototype pistol was produced on 10 May 1921, which Gordon Bruce states was referred to as the “Serbian Model.” Two further prototypes were produced, chambered for the 9mm Steyr cartridge, one of which was shipped to Greece. A new military model was submitted to the War Office for testing in the second half of 1923 but, since no ammunition was sent with the pistol, it was merely examined rather than tested. Stephen Cuthbertson suggests it might have been chambered for the Czech Nickl (vz22) cartridge which was nominally the 9mm Browning Short, though the Czech loading was more powerful. However, Gordon Bruce mentions that “[a]ttention was drawn to the fact that the new pistol also accepted a longer cartridge,” presumably longer than that of the Model 1908 (chambered for the 9mm Browning Long) with which it was being compared, but this is not completely clear. Cuthbertson relates: “The question still exists, then, as to whether or not the ammunition has been correctly identified.” I suggest that if the new pistol accepted a longer cartridge it might have been the 9mm Steyr, and perhaps ammunition was not submitted with the gun because the Steyr cartridge was too powerful for the unlocked breech design of the gun; but no one knows for certain. Nothing came of the new 9mm design for several years. Then, in 1924, the South African Union Defense Force (UDF) began searching for a military sidearm. What they wanted to buy was the German-made Parabellum Luger, but the Luger was considered too expensive. The 1925 Webley & Scott catalogue listed the 9mm pistol as the “Webley & Scott New Military & Police Automatic Pistol - 9mm.” The gun was 40% cheaper than the Luger, so the UDF placed an order for 1000 of them sometime late in 1925. Up to this point, Webley & Scott had only assembled a few of the pistols. They had to ramp up production considerably in order to have the first 200 pistols ready by January 1926. Much of the rest of 1926 was consumed with completing the order. Because of this one large order, the pistol is often referred to as the African Model. The gun remained in production through 1929, though sales of remaining stocks continued until 1931. Total production was about 1900 pistols.*

In September of 1949 a Polish engineer, Marian Karol Jurek, was hired by Webley & Scott to produce an automatic pistol for military use. The British Standing Committee on Infantry Weapons and Development had already decided to standardize on the 9mm Parabellum cartridge (or its British equivalent known as the 9mm Mk.2Z) due to the success during the war of the 1935 Browning-derived Inglis pistol chambered for that cartridge. By 1952 Jurek had produced a prototype, and a second in 1953. Both prototypes are shown in Bruce’s book (pages 298-303), and the second prototype is shown in Cuthbertson (pages 105-107). The design is a pastiche of elements from other well-known pistols, including the twin swinging link breech lock mechanism designed by John Browning and used in the Colt Model 1900; trigger, lockwork, and recoil springs from the Walther P38; and main spring and grip attachment method from the Tokarev pistol. Apparently the design was so derivative there was not a single element that was patentable. The gun was a double action on the first shot, single thereafter, with an eight -round single-stack magazine, a slide that locked open on the last round, and a magazine safety. Unfortunately, the primary competitor for Jurek’s design was the 1935 FN Browning, which

proved more dependable, was four ounces lighter than the Webley & Scott pistol, and featured a thirteen-round double-stack magazine. The British military gave the Webley & Scott pistol a fair

test, but the virtues of the Browning design were reaffirmed in side-by-side testing, so they really had no choice but to select the Belgian-made gun. In 1954 the 1935 Browning “High-Power”

became the standard sidearm of the British military, and was given the designation L9A1. Sadly, with their military and commercial markets gone, Webley & Scott never again manufactured a real

handgun. Webley & Scott Automatic Pistols: Part 1 (1903-1907) * Please contact me if you have information about, or can provide photographs of, Webley & Scott automatic pistols discussed in this article: edbuffaloe@unblinkingeye.com. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2019 by Ed Buffaloe. All rights reserved. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||