|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

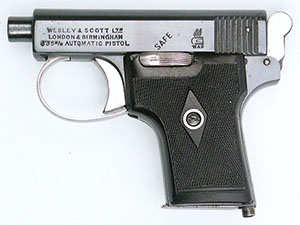

Webley & Scott Automatic Pistols by Ed Buffaloe The Model 1908 6.35 mm - Standard Hammer Model

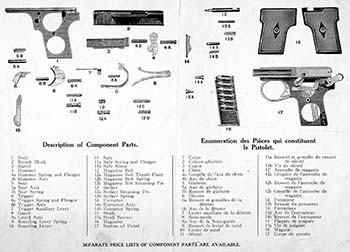

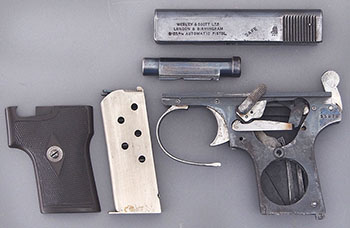

Webley & Scott never made a clear distinction between their older and newer model pistols, referring to both as the “Automatic Pistol, .25 or 6.35.” However, the newer pistol is referred to in some catalogues as the “Improved Model,” with no elaboration as to improvements. Neither William Dowell nor Gordon Bruce distinguishes the Model 1908 as a separate model, likely because the late Model 1907 pistols are externally very similar to the early Model 1908, so it seems as if there is a continuous evolution of a single model. But on closer examination, there are numerous differences. As Cuthbertson points out, most parts are not interchangeable between the two models—on the late Model 1908, only the magazine. Cuthbertson calls the new gun the “Standard Hammer Model of 1908.” The most obvious external difference between the two guns is the curve of the upper portion of the grip, though in fact the Model 1908 frame is thinner than that of the Model 1907 by a couple of thousandths of an inch, and the slide is shorter by almost four-hundredths inch. Underneath the grip plates the real changes are apparent. The leverage post for the long limb of the V-spring is moved from just behind the trigger of the Model 1907 to the rear of the grip frame on the Model 1908, and the roller on the short limb of the spring is eliminated. The shape of the recoil lever is considerably altered. The grip frame cutouts are now round instead of rectangular. The grip plates themselves are externally identical, but have a different configuration on the reverse and do not interchange between the two models. The cam on the safety lever is reduced in size. Under the left grip, the lockwork and safety have been redesigned. Neither gun has sights of any kind.

In 1910 a special order was placed for 100 pistols with front and rear sights. These were in the serial number range between 54200-54299. Please contact me if you have one and can provide photographs.* In 1911 the cam on the safety lever was redesigned, as was the transfer bar. The cam was enlarged and reshaped in such fashion that when the slide was out of battery it depressed the cam which in turn depressed the transfer bar, disconnecting it from the sear. In earlier guns, the falling hammer cammed the transfer bar down, but in the new guns disconnection was tied to the position of the slide rather than the hammer. The new design also prevented the gun from being disassembled unless the safety was engaged.

The slide legend remained the same as on the earlier pistols, though the spacing of the letters on the first line was increased over time. Eventually the serial number on the left side of the frame was eliminated and serial numbers were only stamped on the back of the grip strap. Pistols exported before World War I were stamped MADE IN ENGLAND on the left side beneath the three-line inscription. After World War I the export stamp was moved to the right side, along the bottom edge. Retailer marks were also stamped on the right side of the slide. According to Cuthbertson,

According to Gordon Bruce, manufacture ceased after 1932, but guns continued to be assembled from parts through December of 1939, when the last one, serial number 163109, was assembled.

Bruce gives total production as 50,342, but he is combining both the Model 1907 and the Model 1908. Cuthbertson says that the last serial number produced was 163248 in 1940, and he gives an

estimated total production for the Model 1908 of just over 48,000.

The Model 1908 .32 Caliber Standard Model

In 1908 Webley & Scott began retooling for an updated version of their .32 caliber pistol, but according to Cuthbertson production did not actually begin until early in 1909. Both Gordon Bruce and Stephen Cuthbertson refer to this gun as the Model 1908. Some of the changes introduced in the 6.35mm Model 1908 pistol were adopted for the .32, but the gun also carried over many features from the late Model 1905 transitional pistols. The transitional pistols already had the thin hammer with a hole drilled through it, the short extractor, the sighting groove instead of a rear sight, the retaining pin for the striker (necessitated by the elimination of the rear sight), and Whiting’s lever safety. The button safety patented by John Carter and Frank T. Murray was a much better, safer design, but the lever safety was simpler and cheaper to produce and was already a standard feature of the late transitional pistols.

The scalloped areas on each side of the slide above the trigger guard of the early Model 1905 were eliminated in late transitional pistols, simplifying machining for the slide and giving it a more squared-off look. The trigger was made thicker by about .04 inches and was set further to the rear in the trigger guard. The transfer bar was simplified somewhat and completely hidden under the left grip plate. The roller on the recoil spring was eliminated and the recoil arm and spring were redesigned in a similar fashion to the Model 1908 6.35 mm. Finally, the pivoting trigger guard and button magazine release from the Model 1907 6.35 mm pistol were adopted for the .32. The pivoting trigger guard meant the barrel only needed a single retention notch instead of two, thus simplifying its machining; but the spring steel trigger guard no longer served as a recoil buffer.

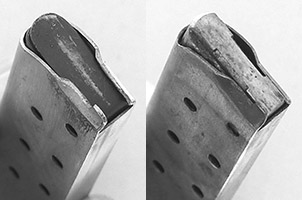

According to Cuthbertson, the early magazine release buttons were cut with five concentric circles to prevent finger slippage. These were later reduced to four and then three. Grip plates were of

hard rubber, with walnut plates available for a premium. Third-party aluminum grip plates were offered after the war because the hard rubber plates were so easily broken.

The Model 1909 in 9 mm Browning Long

The first patent (1908-19,177) was for the slide hold-open mechanism. The second patent (1909-1664) covers a lanyard which serves as the magazine release; however, in the actual implementation of the pistol the lanyard is simply attached to the frame and the magazine release is a button as on earlier pistols. The third patent (1909-2569) covers the grip safety, which incorporates the hammer and sear in a removable module. The fourth patent (1909-2570) is an update of an earlier patent (1908-18,567) for the hinged trigger guard which serves as a barrel locking mechanism.

The grip safety functions in such a manner that when depressed it moves the sear forward into a position where the transfer bar can engage it. When the grip safety is not depressed the sear is out of reach of the transfer bar. There is no mechanism to lock the hammer or firing pin. The disconnector sits just behind the trigger. It is depressed by the recoiling slide and moves the transfer bar down just enough that when the trigger is to the rear the transfer bar cannot reach the sear. The left side slide inscription is in all-capital sans-serif characters more or less centered on the left side of the slide, as follows: WEBLEY & SCOTT LTD. The W&S winged bullet logo is at the front of the slide. Late pistols have the inscription moved closer to the front. The serial number is stamped on the left side of the grip tang, as well as on the bottom of the barrel and slide. Webley & Scott had absolutely no hope of obtaining a British military contract for this pistol, as the government was firm in its insistence on a .45 caliber pistol with greater man-stopping

potential. However, the Swedish military had adopted the 9mm Browning Long cartridge in 1907, and Webley & Scott believed there might be a market for a less-expensive weapon chambered for

the same cartridge. In any case, all that was really needed was to scale up the existing .32 caliber pistol and add a grip safety and a mechanism to lock the slide on an empty magazine to meet

military requirements. But sales proved disappointing and, according to Gordon Bruce, only 1694 were ever made. The general consensus as to why the 9mm Browning Long never achieved

widespread acceptance is that it was underpowered when compared with other military cartridges of the day such as the 9mm Parabellum, the 6.3mm Mauser, and later the .45 ACP.

Webley & Scott and William Whiting never lost sight of the original goal of creating a locked breech military pistol. In late 1909 three locked-breech .455 caliber automatic pistols were manufactured for testing purposes. Four more were produced in 1910, twenty-one in 1911, and five in 1912. A scant few of these pistols were actually sold on the commercial market, first appearing in a Webley & Scott catalogue in 1911, and referred to as the .455 High Velocity Automatic Pistol. Most were reserved for military testing, and there were a number of minor variants. Some test pistols were refurbished and sold commercially. These guns used the breech lock mechanism patented in 1906 for the .45 caliber experimental model, with angled ribs on the side of the barrel that fit into angled grooves in the frame. According to Gordon Bruce, the British Navy tested the pistol in September of 1909, and made a few suggestions for changes: reposition the grip safety, reduce the trigger pull, and provide a means for firing single rounds while holding the full magazine in reserve. In August of 1910 the gun was tested alongside the latest Colt .45 automatic. By the end of February 1912 the .455 was adopted for limited use by the Royal Navy. Full adoption came in 1913 (see below). The left side slide inscription is in all-capital sans-serif characters, as follows: WEBLEY & SCOTT LTD. The pistol was initially chambered for an improved rimless .455 cartridge with a wide extractor groove and a very thin rim. The metal-cased round-nose bullet weighed 224 grains. In 1912 the rim thickness was nearly doubled to .048 inches, and the .455 Webley Auto cartridge was standardized. In 1909 thirteen pistols were made chambered for the .38 ACP cartridge, which had been introduced by Colt’s in 1900. These guns differed from the .455 in that they had an internal hammer . Another thirteen pistols were made in 1910, with grip safeties, and some with external hammers. The part holding the barrel and slide together is a heavy pin (referred to as a roller) with a slot cut in it, in which rides the recoil lever on the right side of the gun and which, on early guns, pierces only the right side of the barrel and slide. This quickly gives way to a combination recoil lever and slide stop, which is a thick pin that runs through both sides of the gun and is retained by a screw on the right side. This in turn gives way to a similar pin with a lever on the right side. When the lever is flipped up, rotating the pin, the pin can be withdrawn to disassemble the gun, but is retained in the slide by a screw on the right side. Since the recoil lever rides in a slot in the slide stop, a method of holding the lever out of the slot had to be devised in order to remove the slide stop. This function is performed by the button on the right side of the gun. When the slide is drawn back about a quarter-inch and the button is depressed, it locks the recoil lever a quarter-inch to the rear.

In 1910 William Whiting patented a mechanism whereby a side safety lever could also be used as a release for the slide hold-open mechanism. The hold-open mechanism itself was identical to that of the 9mm Model 1909, but the release was effected by pushing the safety lever upward past the FIRE position instead of a button on top of the slide. This side safety and slide release mechanism was installed on approximately the last 365 guns made in 1911, replacing the grip safety. Bruce refers to these guns as Type III (later pattern). The left side slide inscription is in all-capital sans-serif characters, as follows: WEBLEY & SCOTT LTD. The .38 Military Model was tested by the Metropolitan Police, but during testing was found to be unsafe if dropped (a test gun discharged a round when dropped) and so was not accepted. Only

930 of these pistols were manufactured in .38 ACP caliber and, failing adoption by the Metropolitan Police, production ceased at the end of 1911.

The Model 1910 in .380 Caliber

Almost as soon as William Whiting learned of the new cartridge he wanted to use it in a gun of his own design, so he began considering what modifications might be necessary to adapt his .32 design to the .380 cartridge. Four prototypes were made and tested during 1909. According to Cuthbertson, production began in the Summer of 1910 at serial number 55047. The new gun was essentially the same size as the .32, so it required only minimal tooling changes. The production gun used the tried-and-true V-spring and recoil lever under the right grip, though the recoil spring had to be more powerful to handle the new cartridge. The barrel, of course, had to be bored larger, and the magazine well, but the external dimensions were effectively the same, and the slide was identical to the .32. Most other internal parts were interchangeable between the .32 and .380. Only about 200 guns were manufactured in 1910 before a recoil buffer lever was added. This feature had been patented in 1907 (British patent 1907-1601) but had not been deemed necessary on the .32 and so was omitted. But the greater recoil of the .380 cartridge made the buffer necessary to prevent damage to the frame. A cut was made in the bottom rear edge of the chamber of the barrel. This cut engaged the top of the recoil lever. The barrel of the .380 pistol moves approximately one millimeter under recoil, buffered by the recoil lever tensioned at its lower end by the spring steel trigger guard. Bruce provides photographs of the buffer lever, trigger guard, and barrel on page 172, whilst Cuthbertson provides a diagram on page 111. The left side slide inscription is in all-capital sans-serif characters, as follows: WEBLEY & SCOTT LTD. The inscription was placed toward the front of the slide, and the W&S winged bullet logo was placed at the rear. The serial number is on the left side grip tang. In 1913 the trigger was redesigned to have less curvature, so its bottom sits a little further back in the trigger guard. The Webley & Scott .380 never sold well, and only 2129 were ever made. Production ended in 1932. Some of these pistols (maybe as many as 250) were used by the South Australian Police between 1913 and 1961, and were marked with the letters S A P over a broad arrow.

The Metropolitan Police (M.P.) Model of the .32 Automatic

Suffice it to say that the Webley & Scott .32 auto pistol, with a few minor modifications, was eventually chosen for use by the Metropolitan Police. (The M.P. pattern was simply a variant of the standard Model 1908 in .32 caliber.) Gordon Bruce states, “[a]doption of the calibre .22 and .32 Webley & Scott pistols was officially sanctioned by the Home Secretary, Winston Churchill, in October 1911.” Delivery of the pistols commenced in November 1911. Minor changes requested included a trigger pull less than 8 pounds, a mechanism to hold the slide open when the magazine is empty, and a more positive safety that could not be accidentally disengaged. Due to accuracy requirements, the company itself decided to add a better rear sight, which consisted of a fixed, raised V dovetailed onto the rear of the slide. The slide hold-open mechanism was simply a reinforced, raised magazine follower that rose up and prevented the slide from closing when the magazine was empty. The slide closes as soon as the magazine is withdrawn—it merely serves as an indicator that the weapon is out of ammunition.

The Model 1911 .22 Caliber Practice/Target Pistol

The identical frame casting is used as in the .32 but it is machined differently. The recoil spring and recoil lever are eliminated, and the slide is cut away at the top so the barrel sits further back and the breech block is at the very rear of the slide. Due to the set-back of the barrel in the slide, the barrel is lengthened to provide the same heft as the .32. The gun is a single-shot, so no magazine is necessary, leaving room on the bottom of the grip for a slot to attach a shoulder stock. Since there is no recoil spring, the slide stays open after the

Recoil is absorbed almost entirely by the hammer spring. A small spring and plunger are installed in the base of the breech block. The plunger fits into a V-cut on the left side of the frame to hold the slide closed when the hammer is cocked. The spring and plunger may also help retard recoil slightly, as they are compressed when the slide recoils. Early guns have two V-cuts immediately behind the chamber. Later guns have a single V-cut, set back a few millimeters (in essentially the same position as the second cut on the early guns) and the spring and plunger are installed correspondingly further back in the breech block.

The left side slide inscription is in all-capital sans-serif characters, as follows: WEBLEY & SCOTT LTD. The right side of the slide is also marked in all-capital sans-serif characters, as follows: .22 RIM FIRE LONG The serial number is on the left side grip tang. The gun was manufactured through September of 1932, but demand was low. Cuthbertson states that total production was only 1400 pistols.*

Collectors wishing to shoot these guns should use standard velocity ammunition only—most modern ammunition is too powerful. Webley & Scott Automatic Pistols: Part 1 (1903-1907) * Please contact me if you have information about, or can provide photographs of, Webley & Scott automatic pistols discussed in this article: edbuffaloe@unblinkingeye.com. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2019 by Ed Buffaloe. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||