|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Czech ČZ-24 Pistol Historical Narrative By the second half of 1922, the Czech Ministry of Defense was already considering transferring production of the new Czech army pistol, then known as the vz. 22 (Model 1922), from Zbrojovka Brno to one of the other Czech arms factories. Pistol production at Zbrojovka Brno was proceeding much more slowly than expected, and the factory was struggling with quality control issues. Since machinery for the manufacture of Mauser Model 1898 rifles had been installed in Brno, the Ministry of Defense considered it more important for Zbrojovka Brno to concentrate on rifle manufacture. In late October of 1922, the Česká zbrojovka (ČZ) directorate first discussed the possibility of taking over production of the vz. 22. According to Jan Skramoušský in his book Československé pistole 1918-1985, the director of Zbrojovka Praga (the Prague Arms Factory), Bedřich Schreiber, prevailed upon the director of Zbrojovka Brno to submit the decision as to which company should take over production of the vz. 22 to the Czech Industrial Bank. Perhaps Schreiber assumed that, since both the director and the procurator of the Czech Industrial Bank were investors in Zbrojovka Praga, they might favor it for the contract. However, the bank management assessed the conditions of both Zbrojovka Praga in Prague and Česká zbrojovka in Strakonice, and recommended Česká zbrojovka for the work. The military armaments commission made their final decision in favor of Česká zbrojovka on 19 February 1923.

This decision was made none too soon for Česká zbrojovka. The company had already begun manufacture of a 6.35 mm pistol with interchangeable parts, known as the Model 1922, but the gun was not selling well and ČZ was sliding into bankruptcy. At the end of 1922, the company owed their creditors more than 3,893,490 Czech crowns and, by 4 May 1923, the total debt had reached 15.5 million crown. František Myška, one of the engineers at ČZ, who joined the company on 15 January 1922, at the age of 23, recorded some of his memories of that time: In 1923, we started producing civilian 6.35 ČZ pistols. We reconstructed this pistol from the Fox pistol...under the guidance of engineer Zalubowski, who was an excellent gunsmith and from whom we also learned a lot. The gun had interchangeable parts. At that time, the Zbrojovka Brno had a Mauser-Nickel army pistol in production. Since Zbrojovka Brno was unable to produce pistols with replaceable parts, while we were able to do so on civilian pistols, the military armaments commission considered transferring the production of army pistols from Brno to Strakonice. Our director at the time, engineer Beneš...invited the general of the military armaments commission to inspect our plant and become convinced that we had a tolerance system allowing us to produce interchangeable pistol parts. This was the salvation of the Strakonice armory—because the civilian 6.35 pistol could not support the company and its employees. The invitation was accepted, and a group of senior officers... came to Strakonice. [This visit took place on 23 May 1923.] They inspected the plant (it was very small then), and the test of pistols and nerves...began. [T]he commission randomly selected 10 assembled ČZ 6.35 pistols. They put them all through a function test—they all worked fine. These pistols were no longer allowed out of their sight. Next followed a test of the interchangeability of their components. ...the listed 10 pistols were disassembled—the parts were put on the stand and mixed by the commission (the parts were not marked in any way). Now, before the eyes of the commission, all ten pistols were reassembled. Now a very serious event was ahead—will it work or there will be some glitches, and all of us, including the director, prayed in our hearts that it would work out, because it was the salvation not only for our armory, but for all the employees. After assembly, the pistols and cartridges went into the hands of a member of the commission who tested the function of each pistol with two magazines. The guns worked flawlessly. The joy was great not only on our side but also on the side of the military commission. On the basis of this test, the military armaments commission decided to transfer the production of the 9 mm army pistol from Zbrojovka Brno to the Strakonice Armory. On 13 June 1923, ČZ agreed to accept a military order for 20,000 pistols, despite the fact that the order was too small to be profitable considering the outlay of funds necessary to tool up for production. ČZ did not have the equipment necessary to manufacture the army pistols, nor the money to buy it, so their acceptance of the order was on the condition that they receive a considerable cash advance and, assuming the guns met the needs of the military, the company was to receive a further order for at least 100,000 pistols or the military would be required to buy back the production equipment. A contract was eventually negotiated more or less on these terms, providing ČZ a cash advance of 3,700,000 Czech crowns, which was paid on 15 February 1924. A production plan was drawn up. If each operation were to require a separate machine tool, 425 machines would have been necessary. If 74 machines were converted for a second operation during the second shift, the total machines necessary could be reduced to 278. At the time of planning, ČZ possessed 101 machine tools that could be adapted for use on the army pistol. ČZ managed to obtain 16 unused machines from the Škoda factory in Pilsen, and another 37 from Zbrojovka Praga. An additional 71 machines were made to order by Škoda, and 53 additional machines were purchased from various European suppliers, including Ludwig Loewe of Berlin, F. Werner, Curd Nube, Hillewerke, Samsonwerke, Krause & Co., Carl Unger, Behling & Lübke, and Pittier. The factory had to be enlarged by approximately 2200 square meters (23,680 square feet). ČZ had originally requested five million crowns and, ultimately, the cost for the 150 new machines and the expansion of the factory to accommodate them totaled 4,670,000 crowns.

Sample vz. 22 pistols were supplied by Zbrojovka Brno and, during the second half of 1923, these sample pistols were measured for tolerances, analyzed, modified, and tested. The Russian engineer Anatoly Petrovič Zaljubovský (1859-1936), who had successfully organized production for the 6.35 mm ČZ Model 1922, was put in charge of the redesign of the army pistol, assisted by the young František Myška and other engineers, including some who came over from the Skoda plant and from Zbrojovka Praga. R. J. Berger states that a number of changes were recommended by the design engineers, which were approved by the armaments commission in February of 1924. By early in July of 1924, the redesign was mostly complete, with detailed drawings, tolerances, and measuring tools specified. Skramoušský says: From the minutes of the meeting of the board of directors of the armory, on 19 September 1924, we learn that all devices for the production of the grip, barrel, barrel coupling and magazine were 90% complete, and the devices for the production of the bolt were currently being made and would be completed within the next month. It was assumed that the Ministry of Defense would be able to take over the first series of 200 test pieces during January 1925. This assumption later proved too optimistic...due to delayed deliveries of machine tools. On the same date...2 models of army pistol were completed in the Česká zbrojovka workshop and preliminarily tested by engineer Zalubovský. Testing of the first 200 pistols was finally accomplished during the first week of May 1925. Meanwhile, negotiations had begun with the Mauser company over licensing fees. Mauser initially demanded an exorbitant fee for each pistol produced. ČZ countered that they were asking much more than Zbrojovka Brno had paid, and eventually negotiated the fee down, but the process was lengthy and time-consuming. The initial order of 20,000 pistols was complete before the licensing agreement was finally signed, allowing ČZ to pay a fee of seven U.S. cents per gun made.

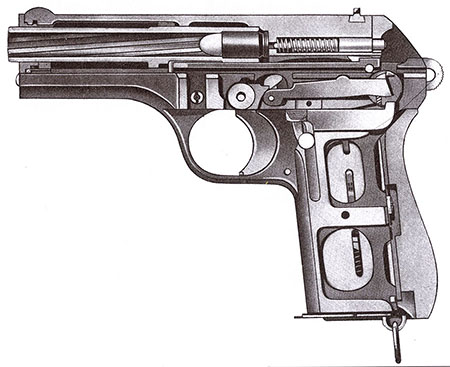

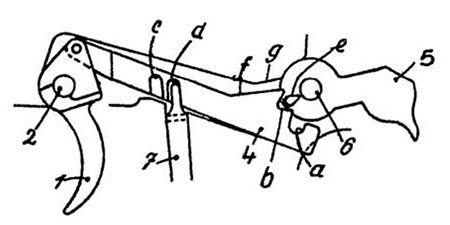

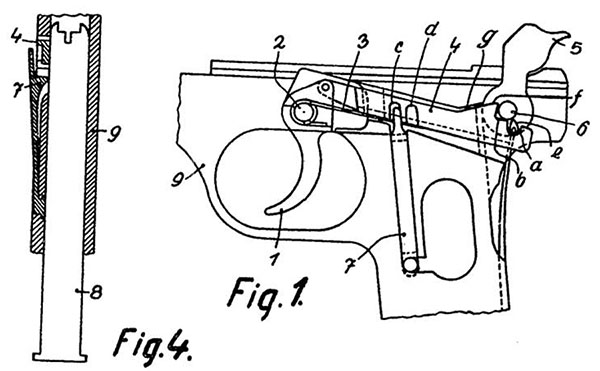

Three patents were filed on 20 March 1925, protecting the design changes made to the vz. 22. The first was Czech patent № 19,391 for the redesign of the lockwork, including the trigger, disconnector, transfer bar, hammer, and sear. The second was Czech patent № 19,392 for the redesign of the rotating barrel and its bearing. The third was Czech patent № 22,427 for a magazine safety. (These patents were filed in other countries as well, including Finland: Finnish patents № 11317, № 11318, and № 11310.) Due to the number design changes, the ministry of defense approved a new model designation for the pistol: vz. 24. Production was approved to begin in August 1925, and the first 20,000 pistols were completed in June 1926. More orders followed, and 100,000 pistols were accepted by the Czech military and gendarmerie by the end of 1931. A further 1400 pistols were purchased from stock by the Ministry of National Defense in 1935. An additional 70,000 pistols were ordered by the Ministry of National Defense on 14 July 1936. Skramoušský says that the last vz. 24 pistols were completed after the war, in 1946, for the Ministry of the Interior. Total production appears to have been somewhat less than 200,000—the highest recorded serial number is 196,658. The ČZ Model 1924 Design Changes ČZ engineers simplified the disconnector mechanism on the vz. 22 pistol, which entailed a redesign of the trigger and the forward end of the transfer bar. The disconnector on both vz. 22 and vz. 24 prevents the trigger from reaching the transfer bar but does not positively lock the transfer bar, the rear end of which serves as the sear. The the vz. 22 disconnector consists of a spring loaded lever built into the trigger which is in turn activated by a second spring loaded lever above the trigger, whereas the second lever was eliminated on the vz. 24—its disconnector consists of a spring loaded lever that pivots on the tranfer bar.

The lower half of the trigger on the vz. 24 remains essentially the same externally, but is quite different internally, as it now links to the magazine safety mechanism. The frame wall extends further forward, allowing no gap behind the trigger and covering up the magazine safety. The vz. 24 frame also extends a few millimeters further to the rear, more fully shrouding the hammer. The safety lever remains the same, but the transfer bar and safety lever on the vz. 24 are tensioned by a coil spring instead of a flat spring. The vz. 22 required that virtually all small parts be stamped with the serial number (or partial serial number) because the gun was hand fitted and parts were not interchangeable—this was no longer necessary on the vz. 24, which had fully interchangeable parts. The redesigned sideplate of the vz. 24 has no ledge at the front (which was to fill the gap next to the trigger) and features a set screw. The grip frame cutouts are made oval in shape on the vz. 24, instead of circular.

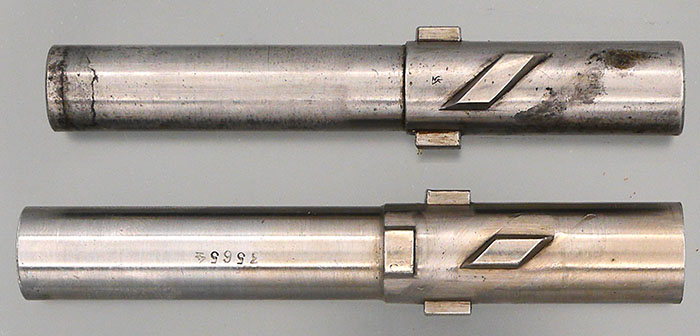

The barrel on the vz. 24 was redesigned. On the vz. 22, the ends of the helical lug on the bottom of the barrel are used to stop its rotation in either direction. On the vz. 24, the helical lug is made much smaller, and an additional stop lug is added in front of the lateral guide lugs, which more precisely limits the turning of the barrel. The stop lug rests against the front of the bearing in which the barrel turns, preventing the lug from dragging against the slide and the barrel from seating itself too far to the rear; friction between the helical lug and the bearing is also reduced. In addition, the bearing itself is redesigned to be symmetrical, so the direction of its placement is optional, whereas the vz. 22 bearing only fits one way and has an arrow on the bottom to indicate the front. The vz. 24 barrel was lengthened by several millimeters, and extends further out the front of the slide.

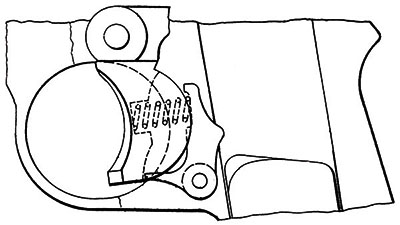

The magazine safety consists of an L-shaped lever behind trigger, tensioned by a coil spring inside the trigger. With the magazine withdrawn about 30 millimeters, the lever is able to rotate backward and its lower extension locks the trigger.

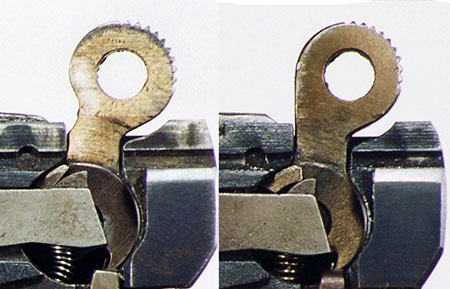

There are two styles of hammer found on the vz. 24. The early hammer has a round head protruding toward the front where it engages the firing pin. The later hammer has a flat face. The hammers differ in the design of their lower portion where they engage the transfer bar. The early hammer cannot be cocked if the magazine is withdrawn—the trigger always remains in the forward position whether the hammer is cocked or not, and the magazine safety blocks the trigger as soon as the magazine is withdrawn. The design of the late hammer with the flat face leaves the trigger slack (to the rear) when the hammer is not cocked; if the magazine is removed, the hammer can still be cocked, but as soon as it is cocked the trigger moves forward and the magazine safety blocks it—this allows the position of the trigger to serve as a visual and tactile indicator of whether or not the hammer is cocked.

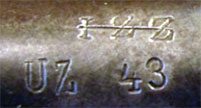

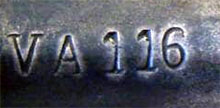

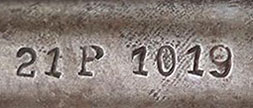

The vz. 24 appears to be rust blued, with the trigger, hammer, safety lever, and safety release button heat treated to a straw color. There are five plunge-milled slide serrations, angled forward, on each side. The front sight is a fixed half-moon, and the rear sight is drift adjustable. The front sight and flat top of the slide have a lightly stippled anti-glare surface. The serial number is stamped on the sideplate, on the right side of the frame at the muzzle, on top of the slide, on the bottom of the barrel, and on the magazine baseplate. Skramoušský says: “In some cases, especially in the later period, the production number was stamped on the inner surfaces of the sidewall.” Spare magazines were not stamped with the serial number, and late production magazines were outsourced and so bore no serial number. The inscription on top of the slide is in all capital serif characters as follows: ČESKA ZBROJOVKA A.S. v PRAZE ...followed by the serial number and the Czech lion proof. Stamped on the left side of the slide, beneath the serrations, is the early Česká zbrojovka emblem, consisting of an arrow between the initials ČZ, followed by the last two digits of the year of manufacture. The ČZ emblem is also stamped on the side plate in front of the serial number, on the magazine, and on the right side of the frame. Sometime in 1929 the ČZ emblem was changed to the now well known circle containing the ČZ monogram. There are known specimens that lack the ČZ emblem and manufacture date. The proof markings are stamped on the right side of the frame, typically the letter J (later E7) followed by the rampant lion and the last two digits of the year in which the gun was proofed. A tiny lion proof is also stamped on the barrel.

On the front of the grip strap are stamped numbers and letters indicating the military unit to which the gun belonged. The example illustrated above has 154D554, indicating the 154th D (artillery) regiment inventory number 554. (See list of Czech Military Unit Designations.)

The conventional magazine holds eight rounds and has three slots on the left side for viewing them. Like the early Mauser pistols, the magazine follower is solid and designed to lock the slide open when the last round has been fired. Unlike the Mauser pistols, there is no mechanism to hold the slide open when the magazine is withdrawn. Stocks are made of unchecked walnut. In the mid-1930s, checked plastic stocks appear with the circular ČZ monogram at the top. Evaluation of the vz. 24 A ČZ vz. 24 pistol was sent to the Deutsche Versuchs-Anstalt fur Handfeuerwaffen (German Research Institute for Small Arms) in Berlin, which issued its report on 10 December 1925. The gun was judged well made, easy to disassemble, easy to shoot, reliable, with good sights, and safe to carry. The average group diameter at 25 meters was 79 mm (3-1/8 inches). Average muzzle velocity, using ammunition manufactured by Gustav Genschow, was 264.5 meters per second, or 867.78 feet per second. R. K. Wilson says of the vz.24 that it is “...well thought out in every particular. It is extremely well made of first class material...,” and it “...groups very well and is quite easy to shoot with.” His only criticism of the vz.24 is that its grip is too square to the frame and therefore the gun does not point naturally—but he says it isn’t as bad as some guns, such as the Steyr-Hahn 9mm. The initial Mauser design featured a mechanism to hold the slide open when the magazine was withdrawn, but this feature was deleted during the development of the vz. 22, leaving the magazine very difficult to remove when the slide is locked open on the magazine follower; and, when a loaded magazine is inserted, the slide must be manually retracted to load the first round. ČZ vz. 24 Usage of the vz. 24 Outside of Czechoslovakia The ČZ Model 1924 was promoted for sale to Switzerland, Romania, Bulgaria, Turkey, Serbia, Croatia, Slovenia, Poland, Greece, Chile, Columbia, and Latvia. However, the only recorded sales of the vz. 24 were in small quantities to Columbia and Latvia. Bulgaria evaluated the vz. 24 in 1926, but deemed it underpowered when compared with the 9mm Parabellum, and inquired if it could be chambered for the more powerful 9 mm Parabellum cartridge. Poland tested a DAO version of the vz. 24, but did not buy it, instead purchasing the vz. 28 (see below). The vz. 24 was retailed in Germany by Gustav Genschow (GECO) in the late 1930s. It does not appear in available catalogues, but at least one example is known with a proof date of 1937. The Model 1924 DAO (Double-Action-Only) Pistol This version of the army pistol derived from a request by the Polish Army for a reliable revolver. ČZ did not make revolvers in this early period. The director of engineering, Gustav Beneš, asked František Myška if he thought he could design a revolver. The young Myška demurred, suggesting instead that he might design a double-action mechanism for the existing vz. 24. He quickly completed such a design, early in 1927, and two examples were sent to Poland in March of that year. However, the Poles did not buy the DAO gun, perhaps because of its unusual design. The hammer did not remain in the cocked position for succeeding shots, so the trigger pull was always double-action, except that if greater accuracy was desired the hammer could be manually cocked, in which case the gun could be fired single-action. There was no manual safety. Not many pistols have been designed in this way.

ČZ filed for a Czech patent on 7 June 1927, and Czech patent, № 28114 was issued on 29 March 1929. A Spanish patent was filed 26 May 1928 (Spanish patent № 107823), a French patent on 29 May 1928 (French patent № 654920), and a British patent on 7 June 1928 (British patent № 291747).

The DAO lockwork is simple and direct. A hook on the end of the transfer bar pulls on a protrusion on the bottom of the hammer, rotating it backward until the protrusion slips off the hook and releases the hammer to fire the cartridge. But there is a secondary indent a little further forward on the transfer bar and, if the hammer is pulled back far enough, the hammer protrusion will catch on it to allow for single-action fire.

The gun also features a magazine safety consisting of a lever that is lowered to block the transfer bar when the magazine is withdrawn. There are two cuts in the transfer bar to accommodate this lever—one locks the action with the hammer down, the other when the hammer is cocked.

The design of the lockwork shows the influence of Alois Tomiška’s Little Tom pistol. František Myška worked with Tomiška at ČZ for about a year and a half, but of course Tomiška was one of the company founders, whereas Myška was probably the youngest engineer on the staff at the time, so we cannot know exactly how much they may have interacted. Nonetheless, Myška was certainly aware of Tomiška’s Little Tom and probably also of some other prototype pistols Tomiška had designed for military use between 1919 and 1923. It seems likely that Myška was at least able to examine these pistols before Tomiška left the company on 1 July 1923. Attempts were made to market this design to other countries, but none were successful. František Myška is known to have stated that pistols with a “dual-function trigger mechanism” were produced for Poland, but apparently there are no records of sales or shipments, and it is not known whether they were eight- or nine-shot models. The number of Model 1924 DAO pistols made is uncertain. Serial number 12 is in the collection of the Military History Institute in Prague, so perhaps at least a dozen were constructed, perhaps more, but they are extremely scarce. ČZ vz. 24 DAO The Model 1928 (The Polish Model) The Model 1928 was designed by František Myška at the request of the Polish military. The gun features a slightly longer grip, a magazine that holds nine cartridges, and an optional rifle stock which also serves as a holster. It might seem that the extended grip frame was necessary to accommodate the mount for the rifle stock, but this is not so, because there are known standard eight-shot Model 1924 pistols with the rifle stock (Berger shows one in his book, on page 33). The magazine release on the vz. 28 was attenuated at the rear, as was the walnut pistol stock, to accommodate the mount for the rifle stock. The Polish Model 1928 was given a separate serial number range.. The nine-shot pistol was also made without the rifle stock attachment.

Sales or distribution of the Model 1928:

Skramoušský says: “The last dot on Polish exports was the export of parts for these pistols, carried out in 1932. This year, an unfulfilled contract for additional pieces was apparently negotiated, as 722 pistols were completed in October and 21 more were assembled by the end of the year.” Additionally, ČZ sent a sample pistol to Chile on 5 March 1929, another one to Romania in May of the same year, and one with a rifle stock to Estonia on 11 May 1937, but no orders were received from any of these countries.

A total of 231 Model 1928 pistols were made with a rifle stock. A total of 3158 were made without the stock. ČZ vz. 28 w/ Stock ČZ vz. 28 without Stock The Model 1929 in 9 mm Parabellum This gun, chambered for the 9 mm Parabellum cartridge, was designed by František Myška, probably in 1928. It is essentially an enlarged vz. 24, with the ejection port and extractor on top. There are minor structural differences in the frame, but the mechanism remains the same. Skramoušský relates that: “In April 1928, a nine-member Turkish commission visited Česká zbrojovka in Strakonice, which expressed interest in samples of pistols in the 9 mm Parabellum caliber, shortly after which they were already referred to as the Model 29. ...but samples for Turkey were not completed until April 1929,” when eight vz. 29 pistols were shipped to Turkey. The Turkish representative floated possible orders of 4000 pistols for their army, gendarmerie, and customs but, despite ČZ’s best efforts, no orders were ever received. A sample gun was sent to Chile on 5 March 1929, and another to Siam a little later. Skramoušský says: “...it can be deduced that 12 specimens of these pistols were demonstrably produced.” ČZ vz. 29 Field Stripping the vz. 24:

There is no need to remove the sideplate for normal cleaning. The simplest method of reassembly is to place the barrel in the slide and install the barrel bushing. Lay the slide and barrel upside down, and place the recoil spring and bearing over the barrel with the bearing positioned over the helical lug. Insert the magazine in the frame about a half-inch short of fully inserted. Turn the frame upside down and ease it onto the slide. Move the slide all the way to the rear on the frame and, with your third hand, insert the magazine fully. Insert the retaining pin in the frame. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2010-2024 by Ed Buffaloe. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||