|

The Bergmann Pistols

by Ed Buffaloe

Historical Perspective

Theodor Bergmann (1850-1931) was from a family of brewmeisters and innkeepers in Spessartdorf, Germany. Early on he worked for a local stove manufactory, which awakened his interest in the metal working

business. Michael Flürscheim (1844-1912) purchased the Eisenwerke Gaggenau (Gaggenau Ironworks), which was already several centuries old, in 1873; and in 1879 Theodor Bergmann, at the age of 29, became a managing partner in the firm. In the last quarter of the 19th century Eisenwerke Gaggenau manufactured structural steel, bridges, railings, lamp posts, railroad switches, signalling equipment, gas regulators, crushing mills, paint mills, enamel signs, household hardware, stoves, wrought iron fences, bicycles, rifles, and airguns. The company still exists today, making kitchen applicances, and calls itself simply Gaggenau.

Flürscheim received a German patent for an air pistol in 1878, two patents for improvements to the design in 1879, and was granted further air gun patents in the 1880’s. The Flürscheim air pistol was

a close copy of the Haviland and Gunn design which had been patented in the U.S. in 1872. In 1884 Bergmann licensed rights to an airgun patent of Henry Quackenbush. By 1891 Eisenwerke Gaggenau was manufacturing hunting rifles, military rifles, gun barrels, and reloading tools, as well as air pistols, air rifles, pellets, and darts. Bergmann later manufactured a small number of airguns under his own name.

On 6 April 1892 a Swiss patent was issued to the Hungarian watchmaker Otto Brauswetter and Aktiengesellschaft Eisenwerke Gaggenau for a self-loading pistol design. But somehow Bergmann obtained

the rights to the patent from Eisenwerke Gaggenau. Louis Schmeisser was assigned the task of improving Brauswetter’s design. Beginning in 1893, Bergmann filed

a series of patents, one nearly every year through 1901, for mechanisms relating to self-loading firearms, some of which were clearly based on Brauswetter’s

earlier patent. These designs were the work of Louis Schmeisser.

According to Walter, “Bergmann left Eisenwerke Gaggenau in the early 1890’s to exploit Schmeisser’s automatic pistol patents.” The founding of Bergmann’s new company, Bergmanns

Industriewerke, is variously dated between 1893 and 1895. Apparently, Bergmanns Industriewerke made many of the same items as Eisenwerke Gaggenau, including enamel signs,

toilets, stoves, bicycles, guns, ammunition, and later automobiles. Bergmann received many patents over the years for items other than weapons.

Theodor Bergmann himself is often described in the literature as an inventor, though Ian Hogg in his later writings indicates that he was more a businessman and entrepreneur who exploited the

inventions of others, citing in particular Louis Schmeisser, who worked for Bergmann for a number of years. Ezell also states that Bergmann was “...primarily an industrialist and

entrepreneur....” In searching for patents in Bergmann’s name, I discovered that he continued to take out patents on various machines and weapons right up to the time of his death, long after he

had sold his automobile and weapons businesses. Whether this represents the activity of an inventive genius or simply a very shrewd businessman I cannot say.

Early Bergmann Automatic Pistols

Model of 1892. According to James B. Stewart, this was Brauswetter’s design, at least one

prototype of which was tested by the Swiss against their 1882 revolver. The gun is described as a long-recoil locked-breech design, the unlocking of which was accomplished by lateral

displacement of the bolt. It was chambered for the 7.5mm M1882 Swiss revolver cartridge. Interestingly, Hogg and Ezell both state that the locked breech design was never manufactured and

the gun tested by the Swiss was a delayed-blowback action which featured an inclined plane in the frame to delay recoil of the bolt. Whatever the case, the gun had a clip-loaded magazine forward

of the trigger with a pivoting side cover and a simple revolver-style single action lockwork mechanism, as shown in Brauswetter’s patent. Also, according to Hogg, there are no known examples of the M1892 extant.

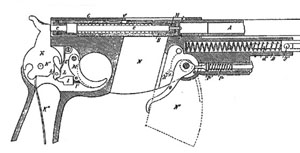

Model of 1894, also known as the Bergmann-Schmeisser, and later as the Bergmann No.1. This model was covered by patents filed in 1893 and later. The gun was similar to

the Model 1892, except that it was blowback operated, with no locking or delaying action. The recoil spring was beneath the barrel. Like the Brauswetter design, the magazine was forward of the trigger guard and had a

pivoting cover on the right side of the gun. The M1894 had no extractor. Several sources state that it was chambered for a 5mm tapered conical cartridge with no rim or groove (eventually designated the

Bergmann No. 1). However, Stewart says that 8mm is the only caliber this gun was manufactured in, and he displays a photograph of serial number 9, which he says is in 8mm. Likewise,

Boothroyd lists an 8mm rimless grooveless “Bergmann-Schmeisser” cartridge, in addition to the “5mm Bergmann Model 94” cartridge. Some sources seem to classify all extractorless Bergmanns

as Model 1894 but, as I see it, the distinguishing feature of the M1894 is the recoil spring under the barrel. Very few of the M1894 guns were made, and I have some suspicion that they may have

essentially been prototypes for the later M1896.

Model of 1896--the Bergmann

No.2, No.3, and No.4. The M1896 was an improved version of the M1894 (covered by patents filed late in 1895). It was primarily manufactured as a pocket pistol in 5mm (the No

.2) and 6.5mm (the No.3), though a limited number of larger guns were manufactured in 8mm (the No.4). The No.2 was also available in a folding-trigger version. The early No.2 and No.3 guns had no extractor and fired

rimless, grooveless cartridges with tapered conical cases; ejection was accomplished by gas pressure and facilitated by the conical shape of the cartridge. However, ejection

was not reliable because the cases did not always strike the ejector at the proper angle and would hang in the ejection port--eventually an extractor was

deemed necessary. The cartridges were redesigned to have grooves, though the unusual conical design was retained.

Barrels on the M1896 were easily removeable for cleaning.

The No.2 pistol barrel was held in place by a single locking lug and a retaining screw. The No.3 and No.4 pistol barrels screwed into the receiver

and were likewise held with a retaining screw. The recoil spring ran inside the bolt, surrounding the striker. A gas escape port was provided on the right side of the chamber,

somewhat reducing the efficiency of the already-weak cartridges. The magazine was identical to that on the M1894. A five round clip was placed in the magazine,

and a spring arm tensioned the cartridges when the cover was closed. The clip could be left in place or removed (using the finger loop), as desired. Hence,

cartridges could also be loaded without the clip by simply laying them in the magazine and closing the cover. R.K. Wilson states that the feed system was unreliable and jams were frequent, whether

the clip was left in place or not. Ejection was to the top, and the ejection port on the Nos. 3 and 4 pistols was covered by a sliding plate. The M1896 was the first Bergmann pistol to be provided

with a means of attaching a shoulder stock.

R.K. Wilson reports that the early Bergmann pistols were available with a lot of special options, including heavy barrels, target sights, hair triggers, and fancy grips.

According to Boothroyd, DWM code No. 416 was the original 5mm rimless grooveless cartridge for the M1894 No.1 pistol, and was also used in the early M1896 No.2 pistol. When the cartridge

was eventually given an extractor groove, it became DWM No. 416A. The early No.3 pistol fired the 6.5mm rimless grooveless DWM No.413. The updated cartridge with an extractor groove was DWM No.413A.

According to Stewart, the No.4 pistol was a variant of the No.3, chambered for a much more powerful straight sided 8mm rimless cartridge with an

extractor groove, which of course was called the No.4 cartridge (DWM No.451). The No.4 pistol was made in limited quantities around 1897, and serial numbers fall in the range between 2300 and 3000.

The later M1896 guns were manufactured by the Valentin Christoph Schilling Company of Suhl (often rendered V. Charles Schilling), because about this time Bergmanns Industriewerke had begun the manufacture of automobiles at

their Gaggenau facility and presumably had insufficient space and/or manpower for the gun

business. “Bergmann” means “mountain man” and by extension “miner.” The logo Bergmann used

on his pistols was a miner. Pistols made by Schilling have “Gaggenau” added at the top of the logo and the letters “V.C.S.” and the word “Suhl” added at the bottom.

|

Field Stripping the Model 1896 Bergmann

- Make sure the chamber is empty.

- Remove the screw at the rear of the bolt on the right side.

- Cock the hammer and tip the gun backward--the firing pin should fall out.

- Remove the rectangular pin through the bolt (to either side) and catch the recoil spring as it exits the rear of the bolt.

- Remove the bolt.

- Remove the bolt cover by lifting at the rear.

|

|

|

Model of 1897, also known as the No.5, or the M1897 Military.

This gun was covered by German patent number 98318, dated 10 March 1897, and was

Bergmann’s first military pistol since the M1892 prototype. It featured an improved version of Brauswetter’s locked breech design. The barrel and breech bolt recoiled

together for 6-7mm, whereupon the barrel was arrested and a cammed surface caused the bolt to be displaced laterally to the right about 3mm, whence the bolt could

continue recoiling, extract and eject the spent case, and feed a new cartridge. The M1897 retained a gas escape port on the left side of the chamber,

similar to the earlier Bergmanns, even though it had a positive locked breech. The gun had a top-mounted spring steel extractor, and the ejection port was covered by a sliding plate. The recoil

spring surrounds the striker, described by Wilson as a “long, thin floating pin.” The cartridge was

a powerful 7.8mm rimless cartridge with an extractor groove very similar to the 7.63mm Mauser. It was known as the Bergmann No.5 cartridge (DWM No.461). A ten round rectangular

detachable box magazine was provided, which could be loaded by clip from the top of the gun if desired. All future Bergmann pistols used similar magazines. The magazine and frame both had

holes to make cartridges visible to the shooter. The grip had a slot on the bottom to take a shoulder stock. Approximately 800 M1897 pistols were made. The U.S. Army Ordnance

Department tested one in 1901, but did not purchase any for further testing.

Model of 1899 or No.6 Pistol. After failing to get a military contract for the M1897, Bergmann

went through a period of experimentation, during which a number of pistols were made for testing, but only the M1897 continued to be produced commercially. The No.6 locked breech pistol may

have been a hybrid of the No.4 and No.5 pistols, and was chambered originally for an 8mm rimless cartridge with an extractor groove, first known as the No.4S and later as the No.7 (DWM

No.460). Two No.6 pistols were tested in Switzerland in 1900. The gun was redesigned in 1901 with some similarities to the M1897, and prototypes were made to shoot the 7.5mm No.7A

cartridge (DWM No.460A) and the 7.65mm No.8 cartridge (DWM No.KK475).

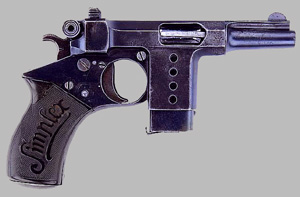

Bergmann Simplex. Eventually the No.6 pistol was reduced in size and simplified into a blowback operated pistol firing the Bergmann 8mm No.6M/06 cartridge

(DWM No.488), said by R.K. Wilson to be similar in characteristics to the 7.65mm Browning (.32 ACP). This final production version of the No.6 pistol was known as

the Bergmann Simplex. The gun had an ejection port on the right side of the frame, and the extractor mounted on the right side of the bolt. A manual safety lever on the left

side of the frame can be conveniently operated by the thumb. The magazine was like that of the M1897. Approximately 4000 Simplex pistols were

made through 1903, but Stewart says that the gun was “not up to Bergmann standards” and “suffered from constructional weaknesses.” Early Simplex pistols were made in Germany by V.C.

Schilling, but later guns were made in Belgium. R.K. Wilson says the Simplex was “...made in Belgium of inferior material and finish.” The Simplex might have had greater success but for the

introduction of the Model 1899 FN Browning, which set the bar for manufacturing quality,

reliability, and accuracy in pocket auto pistols.

The Bergmann Mars of 1903

In 1901 Louis Schmeisser designed (and Bergmann patented) a locked action mechanism for a machine gun, which in 1903 they applied to the design for a new pistol,

which was called the Mars. Externally the gun looked and operated very much like other Bergmann pistols, with the rectangular box magazine in front of the trigger guard

holding six rounds in two staggered columns, and the usual single action revolver-style lockwork. The new locking mechanism featured a hollow cubic block, able to move up

and down in a sqare cut in the barrel extension. The square section bolt fits through this block. A

lug on the bottom of the bolt fits into a recess in the bottom of the cubic block. The block is made such that it has exactly 1/8 inch of vertical play around the bolt. The lower forward and upper rear

edges of the block are bevelled. When the weapon is fired the barrel and bolt recoil together, along with the cubic block, for about 1/4 inch, whereupon the bevelled upper surface of the block,

moving against the upper surface of the square frame section, is forced down 1/8 inch into a recess in the rear of the barrel extension, unlocking the bolt from the recess in the bottom of the block and

allowing it to continue to recoil, extract and eject the spent case, and feed a new cartridge. This is a positive locking action suitable for high-power military cartridges. As in earlier Bergmann

pistols, the recoil spring runs inside the bolt, around the striker. The striker itself is a long, thin pin with a return spring at its point.

Prototype Mars pistols were chambered for the 7.8mm No.5 cartridge (DWM No. 461), the 9mm No.6 cartridge (DWM No. 456), a new 10mm cartridge (never produced commercially), and a

new 11.35mm cartridge (DWM No. 490). The British Chief Inspector of Small Arms tested the 9mm pistol, two versions of the 10mm pistol, and ultimately the 11.35mm pistol, but none was

accepted for British use. Finally, however,on 5 September 1905 the Spanish government placed an order for 3000 of the 9mm Mars pistols for evaluation. Accorcing to Antaris, the Bergmann

was never formally adopted by the Spanish military. However, Ezell states that the gun was recommended for adoption by the Spanish ordnance testing commission and that a royal decree of

5 September 1905 declared it to be the Pistola Bergmann 9 m/m Modelo 1903. Juan Calvo provides nearly identical information.

Bergmann managed to get his 11.35mm Mars to the U.S. Ordnance Department for testing in 1906, but the ammunition for it was impounded by U.S. Customs, so it was not tested. In 1907 he sent a

Mars pistol specially chambered for the .45 ACP. Almost all the manufacturers involved in the tests had complained about the Frankford Arsenal .45 ammunition issued to them, which had

widely varying tolerances. Bergmann had had some .45 ACP ammunition made in Germany, to the correct specifications, but once again U.S. Customs impounded it. Frankford Arsenal was

instructed to provide some .45 ammunition meeting the tolerances specified by Bergmann for use in his gun, but when tested the force of the hammer blow from the Bergmann pistol was insufficient

to ignite the primers, so the Bergmann was eliminated.

Bergmann’s in-house manufacturing facility for guns had always been small, and commercial manufacturing for his pistols had been routinely outsourced to the V.C. Schilling company of Suhl

since 1896. But in 1904 Schilling was bought out by the Heinrich Krieghoff company, which had other plans for the Schilling factory. After completing work on outstanding contracts in early 1905

, Schilling’s cancelled its manufacturing agreement with Bergmanns Industriewerke. Bergmanns Industriewerke set up a small factory in Gaggenau which manufactured less than 1000 Mars

pistols, but only delivered a small number to the Spanish between 1903 and 1908 for testing purposes.

The relatively small 3000 gun contract with the Spanish didn’t justify the tooling up necessary to

manufacture them in quantity, and Bergmann failed to find another large customer for the Mars, so he sold his Spanish contract to Anciens Établissements Pieper (AEP) of Herstal, Belgium. AEP had been desperately seeking new business since they had lost their Belgian army contracts to Fabrique Nationale. Due to the expense of tooling up, AEP insisted that they should also have the

right to manufacture and sell a commercial version of the Mars. At this point Bergmanns Industriewerke agreed to give up making military pistols altogether and turned its attention to machine guns.

The Bergmann Bayard of 1908

Meanwhile, the Spanish Comisíon de Experiencias de Artilleria had been testing the Mars pistols that had been delivered and requested a number of changes to the design.

The redesigned pistol became known as the Model 1908 Bergmann Bayard (Bayard being a trademark of Anciens Établissements Pieper). Perhaps the most significant

change was the introduction of a disconnector to assure that the gun didn’t go full automatic. The barrel was milled out of the solid rather than being screwed in as on

the Mars, and was 1/8 inch shorter. The Bergmann Bayard barrel had six grooves with narrow lands and a left hand twist, whereas the Mars had only four broad grooves with wide lands and a

right hand twist. Other changes to the Belgian gun included adding a hammer stop pin, a larger magazine catch, a shortened throw for the manual safety, a more rounded grip shape, hard rubber

grips, and slightly different contours for the frame and barrel extension. R.K. Wilson described

the Bergmann Bayard as “rather more heavily built” than the Mars. Serial numbers began at 1000. AEP also redesigned the 9mm Bergmann No.6 cartridge, which subsequently became known as the

9mm Bergmann-Bayard, and in Spain as the 9mm Largo.

AEP fulfilled the Spanish contract before the end of 1909. The Spanish guns were stamped with

the early Spanish acceptance proof mark (a circle divided into thirds) on the left side frame bridge and the top of the breech. Also on the left side frame bridge was a four-digit Spanish issue number

. The M1908 was used by the Spanish army until it was replaced by the Campo Giro in 1916, and continued in use by the Spanish police through 1939.

AEP sent test guns to the British and Danish in 1910. The British Chief Inspector of Small Arms issued a negative report, but the Danes placed an order for 4840 pistols,

with modifications. The requested modifications included a simplified disconnector, enlarged wooden grips, finger cutouts on the magazine well, grooved gripping surfaces

on the magazine, an S-shaped mainspring, and a key on the locking block to prevent it from being inserted incorrectly during assembly. Pieper made these changes quickly and

began delivering the guns in 1911. This updated gun became known as the Bergmann Bayard Model 1910. Serial numbers of Danish contract guns range from the low 6000s to approximately

18,000. Most guns feature full Belgian commercial proofs on barrel and bolt, and are engraved with Danish army serial numbers (from 1 to 4840) on the right side of the bridge at the rear of the

gun. AEP also made a small number of commercial pistols based on the Model 1910. The only one we have documented has a 10,000 series number, and does not feature the Bayard horse and rider logo.

AEP made holster stocks for some of their M1910 commercial production pistols. The guns had a

slot cut in the rear grip strap to accept the stocks, which also attached to the lanyard on the bottom of the grip. Commercial guns were produced in the 12,000 and 13,000 serial number range which

were of the M1908 design and featured the Bayard horse and rider trademark on the left side of the

magazine well. AEP referred to these guns as the Model 1912.

Spanish contract and commercial production pistols were marked

ANCIENS ETABLISSEMENTS PIEPER.

HERSTAL-LIEGE.

BERGMANN’S PATENT

in sans-serif characters on the left side of the barrel extension behind the ejection port. The serial number is on the bottom of the frame just below the chamber of the barrel.

The German army overran Belgium in August of 1914 and took over all the arms manufactories in Liege and Herstal. Under German occupation, AEP was forced to continue manufacturing

Bergman Bayard pistols, which by that time were in the 15,000 and 16,000 serial number ranges. These guns either had no proof marks, or featured a single small proof of a diamond with an apple

in the center. Manufacture ceased after the war, but pistols in the 17,000 serial number range were assembled by AEP from existing parts.

After the war, the Danes needed replacement parts for their M1910 pistols, but could not obtain them from AEP, so they decided to manufacture the guns themselves. They

made a few changes, which included further enlarging the magazine catch, replacing the small wooden grips with oversized grips made from Trolit (a proprietary cellulose

-acetate plastic), and replacing the sideplate catch on the right side of the gun with a screw (hidden by the oversize grips). The new gun was designated the M1910/21. Most

existing pistols were eventually modified to these specifications and stamped M.1910/21 on the left side of the barrel extension. Some later models had broken Trolit grips replaced with wooden

grips of the same size. 900 pistols were made between 1922 and 1924 and marked HÆRENS TØJHUS, beneath which was 1910/21

. Another 1904 pistols were manufactured between 1924 and 1925 and marked HÆRENS RUSTKAMMER. Serial numbers began with 1. The army issue numbers

on the guns follow those of the Belgian guns, beginning with 4841 and ending with 7045. M1910/21 pistols have a Danish crown acceptance mark and the last two digits of the year of

manufacture stamped on the right side.

R.K. Wilson sums up his opinion of the Bergmann Bayard by saying: “ The Bergmann-Bayard is a

clumsy, unhandy weapon. The grip is too narrow for the average hand and the pistol, when the magazine is loaded, is very muzzle heavy.” The larger grips installed by the Danes improved the

feel of the gun in the hand considerably. Dennis Adler, in his article in Guns & Ammo, reports that his test gun was reasonably accurate at ten yards.

|

Field Stripping the Bergmann Bayard

- Remove the magazine.

- Draw the bolt back to cock the hammer and make sure there is not a round in the chamber.

- Using a cleaning rod or drift punch, depress the firing pin and remove the retention pin from the right side of the gnurled retraction knob on the bolt.

- Withdraw the firing pin and firing return pin spring.

- Holding a finger over the hole in the bolt (to prevent the mainspring from flying out), press the rear sight forward and pull it up.

- Withdraw the mainspring from the bolt.

- Withdraw the bolt from the back of the barrel extension.

- Push the barrel/barrel extension forward and lift up at the front to free it from the frame.

- Note the orientation of the cubic locking block in the barrel extension--it must be oriented correctly. The later Danish-made guns have alignment

marks on the block and the barrel extension.

Note: When reassembling, the broad end of the firing pin can be used (flat side up) to push the recoil spring in far enough to insert the rear sight in

front of it. The locking block will only go in one way, so its orientation should be carefully noted.

|

|

|

Note: The author welcomes corrections and additional information from informed readers,

as well as additional photographs of any Bergmann pistol.

|