|

Method.

All utensils must be kept clean. More so than with any other

alternative process, cross contamination must be avoided. Use new trays and syringes and wash everything immediately after coating each sheet of paper. The mixed sensitiser will keep for

only half an hour or so, then it will reduce out as metallic gold. Anyone wish to buy a gold plated syringe? All steps to be carried out under low level tungsten light. All utensils must be kept clean. More so than with any other

alternative process, cross contamination must be avoided. Use new trays and syringes and wash everything immediately after coating each sheet of paper. The mixed sensitiser will keep for

only half an hour or so, then it will reduce out as metallic gold. Anyone wish to buy a gold plated syringe? All steps to be carried out under low level tungsten light.

For a 5x4 print: Take 4 drops of the ligand (T.D.P.A.) and add to it 2-3 drops of the gold solution. It should now be apparent that the yellow colour of the gold solution has been

“neutralised” by the ligand and that the solution is now clear. Actually, the ligand converts the gold from its trivalent state (Au+++) to its monovalent (Au+) state. Monovalent gold

chloride requires far less energy to reduce to its metallic gold state than the trivalent gold. Now add 2 drops of ferric ammonium oxalate (f.a.o.) The sensitiser should now be a pale green colour. With some papers,

notably Arches Aquarelle, one drop of a 2% solution of Tween 20 added after the gold can improve the smoothness of the print and prevent image bleed in the developer, especially at low

humidities 50-75% R.H., when much of the image develops out.

Spread the sensitiser over the paper using a glass rod. Two or three passes should be adequate.

Dry the paper using the cool setting on a hair drier and hang the paper in a dark place at the humidity you require. (See note on humidity and image colours) Place your negative in contact

with the emulsion and place in a printing frame. The speed of the sensitiser is about twice that of a normal lithium Ziatype without any contrast (dichromate) additive. However the speed depends

on the paper’s sizing; with gelatine coated papers being slower by about one stop than starch sized papers like “Platine”. Expose to a source of ultra violet radiation i.e. a sun lamp. At

relatively high humidities the image will totally print out and can be inspected and removed when judged complete. At lower humidities there is only a partial print out of the shadow and

mid-tones, so test strips may be necessary however, these must be maintained at the same humidity as the final print.

The exposed print is now quickly and smoothly immersed in the developer at approx. 20 C and

the tray rocked continuously. Developer concentration should not exceed one per cent and you should err on the side of a little less rather than a little more. Again, at high R.H. little or no

development will happen. However with less humidity and partial print-out, the image will quickly appear on immersion and gain density over a period of thirty seconds. The colours may

change from blue through to purple over a period of one to two minutes. With luck, it may be possible to achieve a good split with purple shadows and pale blue highlights. Remove the print

from the developer and place it in a water bath for a couple of minutes, This will curtail any further development. Throw the used developer away...remember it is one shot and should not

be re-used. After several printing sessions you will notice that your brand new developing tray will be plated blue with colloidal gold. Just remove as much as you are able with a damp towel at

the end of each session. Clear the prints in two or three baths of whatever clearing agent you have at hand. Either E.D.T.A. di-sodium, hypo-clear, or “Lime-Away” at the usual percentage

dilutions necessary in Pd/Pt printing. Wash for 30 minutes or so and hang to dry.

Printing Problems.

During my investigation of this process there have

been times when I have been plagued by print defects. Often a particle or two of gold will precipitate out during the coating of the paper and will leave a meteorite trail down the print parallel with the

direction of the glass rod. Obviously these trails will be more apparent in areas of light continuous tone such a skies. If they are small they can often be carefully abraded away in the wash water using a

fingertip. Small spots can similarly be etched away with a knife blades. number of reject prints spoiled by pre-exposure precipitation of the gold seems to

diminish over a period of a few weeks which has led me to believe that the ligand improves with age? Of course, many manufacturers will sell you variations H.AuCl4 3H2O with differing gold contents. The best quality should have a gold content of around 50% but variations may require

recalculation of the concentration of the ligand. If your print includes a border of sensitiser, like mine, this will often bleed into the surrounding picture area, especially at low R.H.’s when much

of the image appears during development. With some papers, the addition of 1 drop of 2% Tween seems to lessen the effect of image bleed. (Brush coating using 50% more sensitiser,

especially with gelatine sized paper seems to cure this problem of image bleed). However, Tween does not appear to be compatible with either Arches Platine or Bergger COT 320. If you find

that this bleed intrusive, then it is a simple matter to mask your borders with a ruby lith film, but with the subsequent loss of those “arty” borders. During my investigation of this process there have

been times when I have been plagued by print defects. Often a particle or two of gold will precipitate out during the coating of the paper and will leave a meteorite trail down the print parallel with the

direction of the glass rod. Obviously these trails will be more apparent in areas of light continuous tone such a skies. If they are small they can often be carefully abraded away in the wash water using a

fingertip. Small spots can similarly be etched away with a knife blades. number of reject prints spoiled by pre-exposure precipitation of the gold seems to

diminish over a period of a few weeks which has led me to believe that the ligand improves with age? Of course, many manufacturers will sell you variations H.AuCl4 3H2O with differing gold contents. The best quality should have a gold content of around 50% but variations may require

recalculation of the concentration of the ligand. If your print includes a border of sensitiser, like mine, this will often bleed into the surrounding picture area, especially at low R.H.’s when much

of the image appears during development. With some papers, the addition of 1 drop of 2% Tween seems to lessen the effect of image bleed. (Brush coating using 50% more sensitiser,

especially with gelatine sized paper seems to cure this problem of image bleed). However, Tween does not appear to be compatible with either Arches Platine or Bergger COT 320. If you find

that this bleed intrusive, then it is a simple matter to mask your borders with a ruby lith film, but with the subsequent loss of those “arty” borders.

Humidity and colour control.

Without going to the trouble of constructing bespoke humidity chambers containing saturated solutions of various chemicals necessary to maintain a constant humidity, it is indeed difficult to

control and maintain a specific R.H. However, an inexpensive hygrometer will give a good indication of the ambient humidity in the room where your sensitised paper is left prior to

exposure. The simplest method is to maintain a room or enclosure at a relatively high R.H. say 80% and to introduce the dried sensitised paper to this atmosphere for a measured period of

time. For example, a print dried with a cool stream of air will still have moisture content of about 50%. Left for 5 minutes the paper will have absorbed moisture from the surrounding air and

have a R.H. of approx. 70% and full ambient humidity of 80% will be achieved after 15-20 minutes. I know this is 'rough and ready', but it seems to work for me. The size of the colloidal

gold particles will determine the colour of the final print. Humidity has the greatest influence of all on the size of the reduced gold, with length of time of immersion in the developer, the choice,

concentration and temperature of the developer being of notable but of secondary importance.

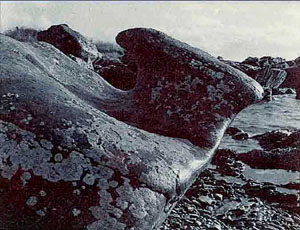

At a high R.H. of 80% and above, there will be full print out and a blue / black image. At a R.H.

of approx. 65 - 70% the print will have maroon shadows, blue mid tones and grey / blue highlights. At a R.H. of 60% and below there will be only partial print out and the print will be

largely maroon with pale grey highlights. Step wedges give an indication of the colours to expect at differing humidities, together with the dynamic range of the process; which is about 14 steps

of 0.15 density units i.e. approx 7 stops. I have experimented with three developers...oxalic, citric, and tartaric acids. There seems not a great deal to choose between them as far as

controlling the colour of the final image. Of the three, I would suggest that oxalic acid, at a dilution of 0.8%, is most efficacious.

Contrast control.

As with the traditional and contemporary Pt/Pd processes, there is no substitute for an original long scale negative. Thin negatives will print with amazing speed and with insufficient time for

proper control. Negatives developed in a pyro developer (P.M.K.) print very well indeed. If a little contrast boost is found to be necessary, one drop of 3% hydrogen peroxide added to the

sensitiser will increase the contrast of the print. Any further addition will lead to print granularity.

Summary.

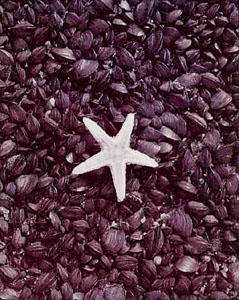

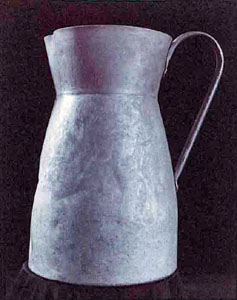

This is indeed an intriguing process but not one for the feint of

heart. I have managed to make, over the course of several months, some of the most exquisite prints of my “alternative” career. Colours and split tones can range from the subtle to the

surreal. I have had neither the time nor the finances to make a full exploration of this process but will certainly return to this technique in the near future. One benefit of this research is

that I now see the world in reds and blues instead of just plain monochrome and I find myself continually looking for photographic opportunities in which to exploit the new palette

of colours provided by this process. One aspect of this process that I haven’t mentioned is that of permanence. Elemental gold is as permanent as platinum or palladium. Prints made with

Pt/Pd family metals have been with us for over a century. I suspect that colloidal gold may be even more archival than that of Pt or Pd. Although these elements are relatively inert, they

do act as catalysts for several chemical reactions which could, in certain special circumstances, lead to breakdown of the paper fibres. The colloidal particles of gold, unlike the dyes of the

colour print, will not fade with time. The beauty and rarity of a carefully made print in colloidal gold will be as permanent as poetry. This is indeed an intriguing process but not one for the feint of

heart. I have managed to make, over the course of several months, some of the most exquisite prints of my “alternative” career. Colours and split tones can range from the subtle to the

surreal. I have had neither the time nor the finances to make a full exploration of this process but will certainly return to this technique in the near future. One benefit of this research is

that I now see the world in reds and blues instead of just plain monochrome and I find myself continually looking for photographic opportunities in which to exploit the new palette

of colours provided by this process. One aspect of this process that I haven’t mentioned is that of permanence. Elemental gold is as permanent as platinum or palladium. Prints made with

Pt/Pd family metals have been with us for over a century. I suspect that colloidal gold may be even more archival than that of Pt or Pd. Although these elements are relatively inert, they

do act as catalysts for several chemical reactions which could, in certain special circumstances, lead to breakdown of the paper fibres. The colloidal particles of gold, unlike the dyes of the

colour print, will not fade with time. The beauty and rarity of a carefully made print in colloidal gold will be as permanent as poetry.

|