|

||||||||||

|

In the footsteps of Niepce by Alan Herbert

Joseph Nicephore Niepce is credited with taking the world’s first photograph,

now on display in Austin’s own Harry Ransom Center. The requirements for an image to be considered a photograph are threefold: the material must be sensitive to light, it must have an image revelation step, and the

result must be permanent. Niepce’s material was Bitumen of Judea, coated on a pewter plate, and it was exposed for a day in a camera with an f4 lens. The image was revealed by washing off unexposed bitumen with Oil

of Lavender. The remaining bitumen provided a visible image. It was upside-down and mirror-reversed. The latter is easily taken care of. The image has lasted 180 years. Practical details. My flat metal plates were obtained first from pop cans, and later from Guinness cans. (Guinness cans gave me a larger plate than the usual pop can, and well, they also have to be emptied.)

The preparation is to cut off the top and bottom of the can, and then slit up the side. The sheet can be flattened by pulling it over an edge – one of my kitchen counters has the proper radius of curvature. Flatness is important for the coating step. Even edges can be obtained using a band saw for top and bottom, and a paper cutter for the side. The edges and corners are sharp!

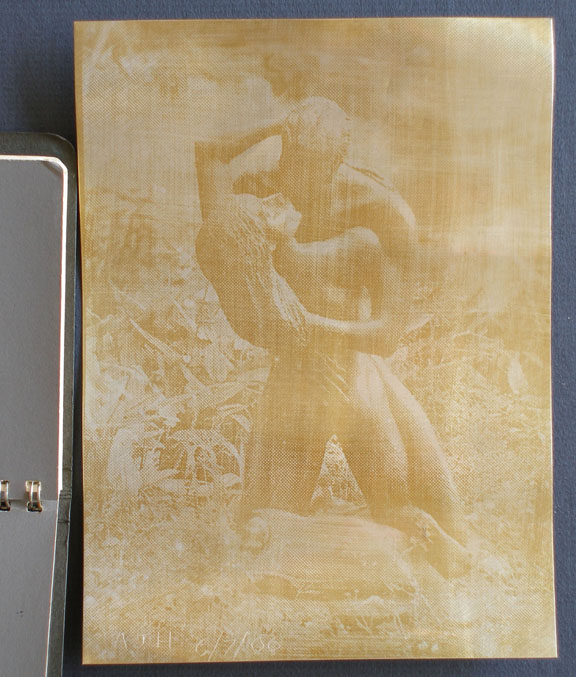

The light-sensitive coating was based on a gallon of Roofing Asphalt (same as bitumen) that I obtained from The Home Depot. A few grams of the nasty black gooey stuff was dripped into a glass vial, and diluted with BBQ lighter fluid. The dilution ratio was important. I found 8X was about right. Paint-brush cleaner also worked, but is a “faster” solvent than lighter fluid. It was coated onto the flat plate (taped to a board), with a disposable, foam paint brush, and left to dry in a well-ventilated place. Note to beginners: these coatings are solvent-based, and care must be taken both with ventilation and fire hazards. Plenty of breeze, and no open flames or sources of sparks, please. The “dry” coating is slightly sticky, but that didn’t seem to give me any problems. It was a light brown color, which gave reasonable exposure times. I contact-printed with a negative (to my slight shame I used a digital negative rather than expose in a camera). My exposure time was about 12 hours, over two days, to Texas June sunlight. (Photo 1). This did a good job of hardening the bitumen, and also partially destroyed my digital negative. It is advisable to allow the contact printing frame to cool for a while, or even place it in the refrigerator. The coating doesn’t stick to the negative so readily if this is done. Then it can be easily separated and developed.

Image revelation was done with BBQ lighter fluid and a smooth paint-brush, in a developer tray. Some images washed off with just a squirt, but Photo 1 took a little more force. The lighter fluid, contaminated with asphalt, I poured back into the container and used it to light my barbeque, thus solving my disposal problem. The image was dried in air for half an hour. Comment. Processes of this type harden from the surface down, due to their inherent color (no color, no visible image). If they receive insufficient exposure, the part of the layer near the base does not harden, and the whole image will float off when developing. This can be avoided by using a half-tone (dot) negative, and giving ample exposure. Niepce didn’t have half-tone technology, but with Photoshop, making a dot negative is relatively easy, so Photo 2 resulted. The coating was thinner (hence the lighter color), and only 6 hours exposure was needed.

I experimented with other wash-off solvents, but the BBQ liquid turned out to be the best. Alcohols didn’t work, and brush cleaner was too aggressive. I did not attempt to find a more-sensitive bitumen. The sensitivity should vary according to source, and it could be pigmented with other materials. With the proper aluminum sheet it

should be possible to make a printing plate – the bitumen should be inkable. The ink in my Bromoil kit dried up long ago, so I didn’t try that! |

||||||||||