|

|||||

|

|

|||||

|

Testing of Printing Sources

1. URI Super Actinic 24" VHO, 75 watts The tests with all of the fluorescent tubes were made in the same four-tube UV exposing unit, powered by an Icecap 430 electronic ballast unit rated to handle up to four 24” VHO tubes. Test Conditions. 1. The exposing negative was a Stouffer TP 45 step wedge. A step wedge is piece of transparent film that consists of 21 graduated densities, beginning at B+F with Step 1 and increasing by approximately log 0.15 per step to a maximum of log 3.00 or slightly higher. Since a density difference of log 0.30 corresponds to one full stop, each of the steps of the step wedge represents a 1/2-stop difference. My personal preference is the 4X5” Stouffer TP 4X5 guide for both film and paper testing.

3. All tests with the fluorescent tubes were made in a four-tube bank powered by an Icecap 430 electronic designed for VHO tubes. The tubes were allowed to warm up for two minutes before beginning the exposure and exposures were made with the tubes at exactly 4” from the exposing plane. It is important to note that the use of the Icecap 430 ballast resulted in printing speeds of about one full stop faster than when the same tubes were tested in units powered with magnetic ballast designed for standard wattage tubes. 4. All tests with the metal halide lamp were with the printing frame at 20" from the light, with the use of a center filter that evens out the light over a 23X29” area. The lamp was allowed to warm up for 5 minutes before beginning the exposure. 5. All tests were carried out with room conditions at about 70F and 55% RH.

Visible Characteristics of the Lights There was a huge difference in visible light between the Super Actinic, BL and BLB tubes. The Super Actinic puts out a very bright, bluish/violet visible light, the BL a bluish light, less intense than the VHO Super Actinic, and the BLB a very pale blue light. The 1000-watt metal halide lamp emits an intense light, bluish/white in appearance. Analysis of Results The step wedge prints were analyzed to determine speed and contrast of each of the combinations of light and process. Speed was determined by the first step wedge that provided maximum density, contrast by the total number of steps between maximum density and paper white. Exposure and Contrast Data from Tests

Platinum Tests Dick Arentz and I collaborated in making tests on Platinum/Palladium similar to the original ones I did with gum, vandyke, kallitype, cyanotype and carbon. Dick coated two sheets of 11X14 paper using his Pt/Pd Mixture #7, then cut the paper into 4X5" pieces and overnighted it to me by FedEx on Saturday. I ran the tests the next day, developing in 25% Potassium Oxalate and clearing for 10 minutes in EDTA. All of the tests have at least two steps of maximum black and all cleared well. Tests included several different 24" fluorescent tubes, all powered with an Icecap 430 ballast. Since this ballast is rated VHO and is electronic its power could not be a limiting factor in light output. The same step wedge was used for all tests, and all exposures were made for ten minutes in the same contact printing frame placed at 4" from the light source. The tubes reported in this article are:

I also tested my HID Mercury Vapor lamp, at 20" from the pod of the lamp to the printing frame, with a center filter. Exposures were also for 10 minutes, after the lamp reached full output.

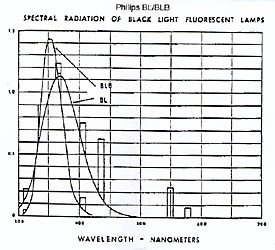

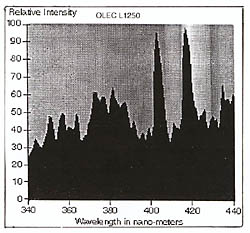

General Remarks about Results. 1. By inspection and simple analysis of the step wedge prints it becomes quickly apparent that in general there is a correlation between image contrast and the wavelength at which the specific light source emits the greater percentage of its radiation, though there are some anomalies in the test data. Light sources that emit most of their radiation at long wavelengths of 400nm and above give images of higher contrast than sources that emit a greater percentage of their energy at wavelengths below 400nm. If you plot a characteristic curve of the step wedges you will find quite simply that long wavelength light gives a greater gamma (or CI) than light of short wavelength. For example, the tonal scale of cyanotype varies from 9-11 steps with different light sources.

2. Relative speed of the processes. a) Cyanaotype is the slowest process as tested. 3. Relative printing speed of the light sources. a) The 5K metal halide unit, used in Mode A, was the fastest by over two full stops of all lights tested, and in most cases it also gave the most contrast. When used in Mode B with the center filter it was faster by about one stop than fluorescent banks powered by ballast designed for standard wattage tubes. b) The GE BLB, Phillips BL, and Sylvania BL gave virtually identical results. In a typical installation with standard wattage ball they are about one stop slower than the metal halide light used in Mode B, and of slightly lower contrast. c) The URI VHO Super Actinic was the slowest light tested, except with kallitype, but gave contrast similar to the metal halide lamp. It is interesting to note that with traditional kallitype, which like Pt/Pd uses ferric oxalate as its sensitizer, the SA light proved to be as fast as the other light sources. This fact appears to be in keeping with the experience of many Pd/Pd users who report that the SA prints faster than the BL.

CONCLUSION All of the UV light sources used in testing for this article are capable of excellent results with any of the processes. However, there are subtle differences involving both contrast and speed that may make one or another of these lights more attractive for a specific process. For example, considering only the fluorescent tubes there is little doubt in my opinion but that BL or BLB tubes are on the whole a better choice than Super Actinic or AQUA. On the other hand, printers working primarily with traditional kallitype or Pt/Pd may find that the Super Actinic or AQUA tubes give better results for them. The use of metal halide lamps imposes other considerations involving ambient impact. There are many factors that must be weighed to determine what kind of exposing unit is best for an individual situation because in the end this is a personal choice that relates as much to work flow and environmental impact as to absolute efficiency of operation. You should consult widely before making a choice, and especially with printers working with the process(s) you are interested in using, because the best advice will come from those with experience. Because ultimately the choice of an UV light is a highly personal one I choose merely to provide some of the advantages and disadvantages of a few systems, without ranking. For the purposes of comparison I am going to assume that the reader is interested in making prints no larger than about 16X20” in size, well within the limits of a typical 1000-watt metal halide light or a bank of 8-12 fluorescent tubes. 1) HID Light The major advantages of this type of light source are, 1) ease of assembly — it can be purchased essentially ready to use, 2) printing speed — it prints faster in most typical conditions than a bank of tubes, 3) low cost, and 4) quality of image — in some conditions the semi-collimated light unit will provide greater apparent sharpness than the diffuse light of a bank of tubes. The disadvantages of this type of unit are, 1) must be left on for several minutes to reach maximum lamp output, and after the lamp is turned off it is necessary to wait for several minutes before it can be turned back on, 2) puts out quite a lot of heat, and 3) there is considerable waste of energy as much of the light radiated is in the green and red area and of no use to alternative processes.

2) Bank of 8-12 24” BL, BLB, AQUA or Super Actinic tubes with magnetic or electronic ballast rated for standard wattage tubes The cost of materials for such a unit would be about the same as for a 1000-watt HID unit. The advantages of this type of unit are, 1) low energy consumption — most of the radiated light is useful to alternative processes, 2) produces very little heat, 3) tubes reach maximum output very soon after powered up, and they can be turned back on immediately after shut down. The disadvantages are, 1) requires quite a bit of time to assemble, 2) printing times will in most set-ups be slower than with a 1000-watt HID unit, and 3) some loss of apparent sharpness may occur in certain conditions, especially when making large prints in contact-printing frames where it is difficult to maintain tight contact between the negative and sensitized emulsion. 3) UV bank of 8-12 24” HO or VHO tubes with appropriately rated ballast The advantage of this type of unit is printing speed. The disadvantage is cost, as HO and VHO tubes are much more expensive than standard wattage tubes, and the ballast rated for HO and VHO tubes is very expensive compared to standard wattage ballast. Also, HO and VHO tubes are available in a very limited number of types and sizes.

KITS and UV Exposing Units http://www.bostick-sullivan.com

http://www.aquadirect.com/lighting/fluorescent.html

https://www.grainger.com/ Copyright notice: This article and all its illustrations are copyright 2001 by Sandy King. All rights are reserved. No portion of this

article may be reproduced by any means whatsoever without the express permission of the author.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|