|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The ÷WA 6.35 mm Pistol by Bob Adair There is an odd and fascinating little pocket pistol known as the ÷WA in 6.35 mm that makes a great addition to any collection of mouse guns. While not ultra-scarce, it isn’t readily found either and information on the pistol is scant for the English-speaking collector. What is available is often repeated across the internet and is often incorrect. In many ways the story is the Austrian parallel to the German Ortgies. A state-owned military arsenal found itself idle in a defeated post-WWI country and transformed into a commercial enterprise making high quality pistols that found few buyers in a cash strapped market. In the end the pistols are dumped at rock bottom prices, in this case even after the pistol was updated to correct some complaints. The difference in stories lies with the design; while the Ortgies was truly an innovative and modern pistol that belonged in the post war world, the ÷WA was an obsolete design at its very birth. This article will cover the background and design of the ÷WA pistol as well as the variations and changes made during the course of manufacture, and it will attempt to clear up mistakes that were established in early sources and continue to persist today. These sources will be compared and analyzed against a census table composed by this author. This approach will provide new insight based on empirical data. We will conclude with a detailed list of variations by serial number. Background:

Perhaps then it is understandable that the need to employ restless workers was the driving factor behind the ÷WA and not the usual free market process; a pistol design looking for a maker. Apparently, the leadership, desperate to make some sort of product, turned to their staff of engineers and designers for help. These men were probably very capable but uninspired old civil servants who looked to the past to design a pistol that, while outwardly resembling its Austrian counterpart, the Steyr M1909 and its Pieper forebearers, was more like the German Mann or Belgian Dictator in size and appearance. It undoubtedly, however, drew its true inspiration from the early Clement pistols. All of these pistols derive from a line of thought and design born out of the very early period of automatic pistols. Although his original design was similar, by 1905 the genus of John Browning had produced a drastically different approach that was simple to make, and that simplicity meant it was also less expensive to produce. The new style of pistols spelled the end to this line of Belgian and Austrian development and makes it puzzling that the leadership at ÷WA would choose a losing proposition from the start! Design:

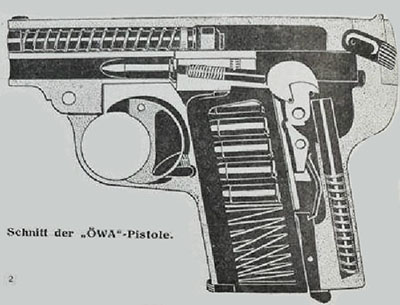

The recoil spring has a long guide arm with a small lug near the end that locks onto the top of the breechblock. Only this small and light weight breechblock moves and is cushioned by both the recoil and firing pin springs during the recoil action. A release lever for the top of the pistol is located at the upper back left side of the pistol. There is no means to hold open the breechblock, which is unnecessary for this design during disassembly, but it would be useful after the last shot is fired. The sights are small and fixed. The front sight is a blade type milled into the barrel assembly. The rear sights are the simple V type and are mounted atop the large lug of the bottom receiver that locks down the barrel assembly. The lower portion of the frame or receiver is milled from a solid piece of steel. The trigger and trigger bar are typical of this style of design, the bar is partially exposed behind the trigger on the right side. Internals are fairly simple; a captured coil spring acts on the hammer, a thin flat spring on the sear and magazine release, and the safety is a simple slide that works by locking a cam milled into the side of the hammer. The magazine release is similar to the Steyr M1909 as it releases a lever that locks into a slot cut into the rear spine of the magazine. The odd thing about this style of release is that the lever must be pushed towards the firing end of the pistol to drop the magazine. The left grip is mounted to a panel that can be removed to expose most of the internal actions. Variations and markings:

One indication that production was rushed is the first of three styles of slide legends used over the production history of this pistol. These slides all read “PATENT ANGEMELDET” (Patent applied for) and the right side reads “MADE IN AUSTRIA.” This legend is found on the few pistols proofed in 1921 and precisely half of the observed pistols proofed in 1922. Assuming production was constant throughout the year, the patent submitted in 1920 was approved as Number 19770 sometime in early summer, which required the slide to be updated. This second slide legend, stamped just on the left side, reads; “CAL 6.35 – ARSENAL, VIENNA AUSTRIA” on the upper line and “Pat. I. A. KULTURSTAATEN" on the lower line. This last phrase translates roughly into “patented in civilized nations.” Serial numbers were applied on the left side of top section of the pistol, under the Austrian Proofs. All pistols are in the same serial range, but very early three-digit numbers have a letter suffix; A, B , C, and D all being observed. A possible pattern may be the serials ran up to a 1000 and started again with another letter. Too few pistols were observed first hand to confirm any pattern.

These pistols also have very unusual assembly numbers. Whereas most pistols of the time had two, maybe three-digit assembly numbers, these pistols had a four-digit assembly number with no relationship to the external serial number. These internal numbers were stamped on both sides of the bottom of the magazine well (since the left panel was removable) and on the bottom hinge of the barrel assembly. The last three and two digits of the assembly number were also used in various locations. During the first few months of production the last three digits of the number were even stamped on the left outside portion of the barrel assembly hinge screw and on the breechblock lug inside. Nearly every part had at least a two-digit number, including the forward right side of the magazine base plate in a very small font. A second set of two-digit numbers, along with various letters, are also found on most breechblock assemblies along with another four-digit assembly number that doesn’t seem to match the rest of the numbers on the few pistols I have been able to observe this closely. Even more perplexing, various letters and numbers can be found on the grip butt, seemingly random. I believe that these letter stamps are most likely inspectors marks, and an example is “V1” over “Z7.” Other letters are found on the top of the slide. Firing pins also have a number and letter, some observed are “5R” and “E6.” Altogether, the methodology behind the ÷WA assembly numbers and butt markings isn’t very clear or straightforward. The grips are another indication that the pistol was quickly put into production before all of the components were ready. The very early pistols have wood grips with long vertical ribs. These are very scarce as they only appear on the first few hundred, perhaps 600 or 700 hundred, but with the serial number letter suffix adding to the possible total, it is tough to estimate.

The grips are mostly checkered and held by a single screw located in the dead center along with a small locking pin on the grip panel. The small banner at top contains the letters “÷WA” from which we get the manufacturers name and it is repeated nowhere else. Despite the patent holders name and the state arsenal and slide legend name changes over time, this “÷WA” is found on all of the pistols with plastic grips. They come in three versions. The first is found only on very early pistols, but with few pistols recorded in my census, the number is hard to estimate. They appeared on less than 3,000 pistols and probably considerably less than that. These grips are distinguished by the “÷WA” in sans-serif font with the double dot (diaeresis or umlaut) positioned over the “O”. For some reason these grips proved unsatisfactory. The grips on one such pistol appeared to be loose on both sides and that may be the fault, but around Serial Number 3500 we see the third style grips; the “÷WA” is now in serif font. This style is by far the most common. The final variation will be discussed below.

Redesign; The Late Model: Several flaws in the rushed design became apparent over time, so ÷WA arranged a fairly major remake, this was probably in the works in the second half of 1923 and perhaps even production stopped in late 1923 for the required retooling of the machinery judging by the number of 1923 proof marked pistols. Collectors have called this the Second or Late variation, resulting in the original design becoming the First or Early variation, but we have no record as to what the factory referred to these changes as. There were enough to merit considering it as different model and for standardization purposes this article will refer to them as the Early and Late Models.

The archaic method of magazine release via the flat spring was dropped in favor of a sliding lock at the bottom of the grips that had become widely used by this time. The slot on the back of the magazines could become worn over time and slip out. Flat springs are also susceptible to breakage over time. It is interesting to note that the magazines in these new pistols continued to have the slot so they could be interchangeable with the Early Model pistols. Internally some changes were also made. One was to the base pin of the hammer. Originally it was pinned only on one side and over time many became bent by the force of the mainspring. The Late Model hammer pin was attached to both side of the frame via a slot on the movable left grip panel. The flat spring that locked the magazine also acted against the sear so it was replaced in the late model with a small coil spring. A large open hole is found on the top portion of the frame, this probably doubled as a weight saving measure and a means to ease production. The shape of the firing pin assembly on the bottom of the breechblock and the hammer changed slightly for unknown reasons. The last style of grips came about due to these internal changes, namely the hammer pin. They are identified by the change in the umlaut; the double dots are now found inside the “O”. This apparently was a change in German orthographic convention that came into popular usage during the 1920s. The method to secure the grips to the grip panels changed as well, but it is visible only from beneath the grips. The new grips had a very large circular stub that fit into a hole cut in the grip plate and the frame’s right side. The holes also helped to lessen the weight. Earlier grips relied on a small pin that locked the grip against the plate and, coupled with the single screw, kept the grip in place and prevented it from rotating. Other changes were primarily cosmetic but were probably undertaken to lighten the pistol somewhat. Serious modifications were made to the shape of the upper portion of the frame near the muzzle and the top portion of the slide. This required significant machining and was labor intensive, so the changes weren’t made lightly or solely for cosmetics. The area above the trigger was changed to a noticeable curve as compared to the straight edge of the Early Model. So much was removed that the serial number had to be moved to the barrel assembly. The total weight of the pistol dropped by 40 grams.

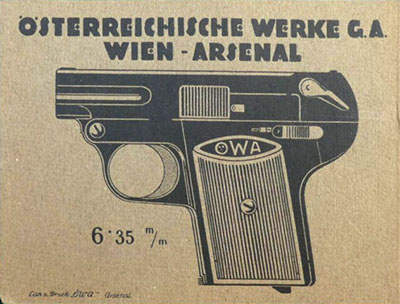

Manual Specifications, and Disassembly: The cover of this manual shows the Early Model and a variation of the full ÷WA name, along with Vienna Arsenal. The fine print on the lower left credits the lithograph drawings to the Vienna Arsenal. One manual has been observed for the ÷WA and it is a very small and straight forward booklet with very limited information. The front inside cover (Page 1) bore the following: For Special Attention

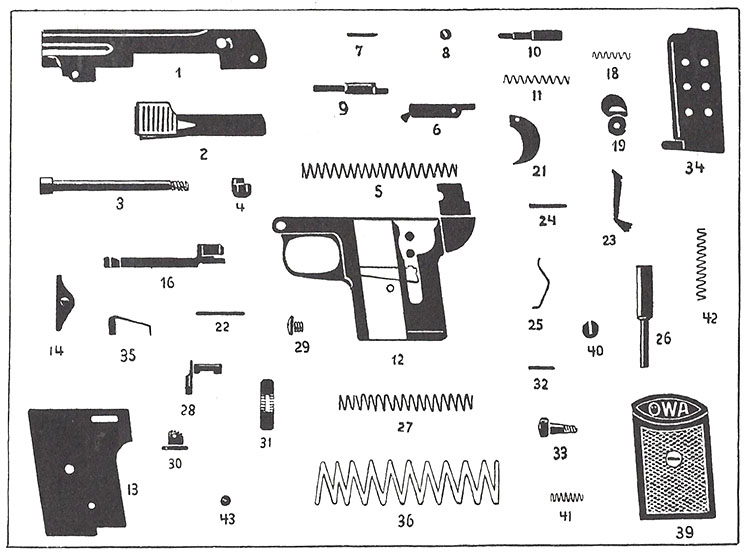

The ÷WA parts are made from high quality materials on precision machines. The parts are therefore easily replaceable, the accuracy is excellent. The amazingly easy disassembly of the ÷WA Pistol allows anyone to do the lightest and most thorough cleaning. The following pages have a short description under an illustration. Examples include pages for removing the magazine, filling the magazine, cocking the pistol, and field stripping. Page 2 had the internal illustration seen earlier in this article. It also included the following illustration and parts list. The specifications of the pistol are provided below.

Disassembly of the ÷WA is fairly easy with the tip up design and is one of the last of the older semi-automatic designs made with the removable side plate to reveal the internal actions. All of the internal parts are easily removable as they are not secured with screws or pins with the grip panel removed.

Reassembly is done in reverse, the only additional note is that the recoil spring must be slightly depressed to get the breechblock fitted back on to the barrel assembly.

Factory Closure, Production Numbers, and Distribution: As stated in the beginning of this article, the ÷WA Pistol arose from a need to employ labor, not from any free market demand. Coupled with no sales structure or experience by ÷WA, the pistol suffered extremely poor sales. Unfortunately, many writers have blamed the problem on poor workmanship and quality of the pistol and the reputation of the ÷WA has since suffered. The problem really centered on the Austrian Arsenal; its postwar transformation from a giant military factory to a civilian led commercial enterprise was a flop. In 1919 arsenal employment was down to 3,000. By the time the ÷WA pistol production began the arsenal was in a state of disarray with a wide variety of haphazard products with little marketing. Capital was quickly depleted and it was not being replaced by sales. A major shakeup at the Arsenal occurred in October, 1924 where the General Director and two thirds of the employees were dismissed. By the end of 1925 there was nothing left but the machine factory and 300 workers. The last few years were marked with liquidations of supplies and equipment and finally the whole affair was ended in 1934. This is important in understanding the story of the ÷WA. It wasn’t simply that it was a poor selling pistol; the world around it fell apart. Sources state that ÷WA produced a total of 40,000 pistols and that is confirmed by the serial numbers of observed pistols. These sources also state that only 8,000 pistols were sold! This doesn’t mean that the rest didn’t ever reach consumers so it must certainly refer to official sales. When we review the census records, there are no large discernable gaps of pistols; surviving pistols are spread throughout the serial range. So what happened to the pistols? Austrian sources state only 8,000 were officially sold between 1922 and 1925. Only 1,000 were sold to any government organization. The Wiener Gemeindewache (Community Guards of Vienna) bought them for the 700-man strong organization charged with guarding state-owned businesses and public parks. Inflation did not help. Pistols sold in May 1922 for 27.600 Kronen were selling for 40.000 in January 1925. As stated before, the Arsenal attempted to update the pistol in early 1924. We see a stop in production in late 1923, this could be explained by the retooling of the machinery for the new model, but manufacturing would end after the massive layoffs occurred in October of that year. In the chaos of this environment, it is understandable that many pistols were pilfered on a grand scale. The ÷sterreichischer Schutzbund (an institution of the Social-Democratic Party) was said to be equipped with some thousand ÷WA Pistols but none of them were purchased. Rather they were illegally procured through arsenal employees. Austrian sources state these pistols have original serial numbers and finish but lack proof marks. Only one such pistol was observed in the census. Another 1,000 pistols or so were stolen by employees smuggling individual parts out of the Arsenal to be assembled elsewhere. These pistols are said to have no proofs and either no serial numbers or up to six digits, with various finishes. The only pistols observed that show any of these traits are several Late Model pistols lacking both serial numbers and proof marks. Austrian sources state that the unsold pistols were eventually liquidated by a "Verwertungs- Gesellschaft" (Utilization Company) for the unbelievable price of 10 Schillings each. As stated before, the Vienna Arsenal did not appear to have any organized sale structure and advertisements for the ÷WA are hard to find. They are not seen in large retailer catalogs of the time like AKAH, GECO, and GECADO. Sales in the US did linger well after production had ceased. One importer in Virginia, L. Oppelman, had them listed in his 1930 Imported & Gun Catalog. Austrian sources list the export of these pistols to the following countries, but this certainly doesn’t reflect the distribution found today. For example, more than one ÷WA is known in Belgium!!!

Legacy: Good reference material on the ÷WA is certainly hard to find. Much of what I read is hard to reconcile while holding a specimen in my hand. The earliest known writing I can find in English is from the classic The NRA Book of Small Arms, Volumme I: Pistols and Revolvers, published in 1945 by Walter H. B. Smith. It contains a photo along with a short description in the main body of the work. After an erroneous German attribution, Smith called the ÷WA the cheapest and simplest automatic pistol ever manufactured. He later summed up the pistol by stating it suffered from poor workmanship while praising the design for simplicity, ease of manufacture, and accessibility for cleaning and repairs. Anyone who holds an example can easily explain his comments concerning accessibility, but the pistol is a small marvel of machining, with the finest steel and immaculate finishing both inside and out; not a piece was left unfinished. The insides of the grip panels even sport a beautiful jeweled finish, and the internals are cleaner than just about every other pocket pistol I have ever observed. I suspect that the American market was flooded with these inexpensive pistols and many people, not knowing the story behind them, wrote them off as cheap and of poor quality without really looking them over with an open mind. We know Smith didn’t pay too close attention to them since in his writeup he shows an Early Model while later on in his specification page he shows a Late Model with no mention of the difference! Dr. J. Howard Mathews in his Firearms Identification written in 1970 has a small and rather accurate description of the pistol but he knew very little of its origin. He took the opposite view of Smith; rather than simplicity, he notes that it is rather over-complicated. I would agree with that assessment, whereas the Browning designed FN Model 1906/Colt M 1908 had only 28 parts, the ÷WA had 45! Hogg and Walter in Pistols of the World provided a short and bland description of both models of the ÷WA. They made no comment on the quality or functionality but did conclude with an error by stating that pistols meant for export were marked “MADE IN AUSTRIA.” As we have discussed, this is found on all pistols with the first slide legend variation. Online sources will mirror much of the above, often repeating comments about poor workmanship. Furthermore, they tend to repeat minor errors over and over, such as the years of production. One comment that often stands out in modern reviews of the pistol concerns its surprising accuracy. While it was a pocket pistol and not a target pistol from the start, the fixed barrel design provides an accuracy many shooters won’t find in their more familiar modern pistols of this size and caliber with a floating locked barrel design. Overall the ÷WA is an interesting pistol, a nice example of old school steel machining, and a small testament to the chaos of post-WWI Europe. It is certainly a worthwhile addition to any collection of fine small arms. Synopsis Of A Census of Known Pistols: The production of the ÷WA pistol was very structured as are most pistols made by the German speaking people. Accordingly, we see consistency in the serial number census regarding the various changes over time; I only saw one outlier. The changes made to these pistols appear to be abrupt and disciplined. The following table takes the information from the serial number census created by this author and displays it in relation to the variations discussed in this article.

Notes:

Credits: Dwight Gruber- For photographs and answering questions on the Late Model. This article was originally published in Automatic Magazine, Vol. LII, Nos. 3 & 4, the monthly organ of the National Automatic Pistol Collectors Association. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2019 by Robert Adair. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||