|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Pistols of Nicolas Pieper by Dr. Stefan Klein, Michel Druart, and Ed Buffaloe

We would be grateful if our readers would provide us with photos and serial numbers of pistols in their possession. Advertisements for Nicolas Pieper’s weapons after the First World War would also be welcome.*

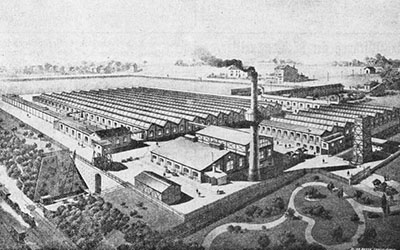

Nicolas Pieper, second son of Henri Pieper and his wife Catherine Elisabeth Leroy, was born in Liège on 31 October 1870. Henri Pieper, a mechanic originally from Germany, founded a company which had its origin in a vast workshop on the rue des Bayards in Liège. This workshop of Henri Pieper was characterized by its mechanization of the manufacture of weapons, whereas previously the work of firearms manufacture was distributed to a multitude of small workshops, other manufacturers being satisfied to assemble parts which were manually produced by these small workshops. Later, Pieper extended his activities with the construction of a factory in Nessonvaux, which became famous for the manufacture of barrels for firearms, including those of high quality shotguns. It is important to bear in mind how dominant Liège gunmaking was in the late 19th and early 20th centuries. Alain Daubresse maintains that: “When Liège production reached its summit, more than half of the firearms made in the world came from Liège...” And the foremost weapon maker of Liege at the end of the 19th century was Henri Pieper. Not only did he own the largest weapon factory in the country, but he was also a founding member and managing director of Fabrique Nationale, and so he had nominal control of the two largest industrial entities in all of Belgium. Pieper’s company was among the first in Belgium to adopt the precision manufacture of interchangeable parts. In 1897, his sons took the initiative and the Henri Pieper company diversified its activities and launched into the manufacture of bicycles, electricity, and gas and electric automobiles. In 1898, Henri Senior, knowing that his death was imminent, ensured the sustainability of his legacy by creating the Société Anonyme des Établissements Pieper. Nicolas, only 28 years old but who already held the reins of the family business, became managing director of the new company; his brother Edouard Herman (also known as Armand) was entrusted with the management of the barrel, bicycle and automobile factory in Nessonvaux. For his part Henri Junior continued to exercise his functions as director of the recently founded International Electricity Company. So the Etablissements Pieper survived for nearly seven years with Nicolas at the helm. The automobile business, however, turned out to be a failure, due partly to the expense of establishing a new manufacturing line, partly to the limited market for automobiles at the time, and partly to mismanagement by Edouard Herman. We cannot know exactly what happened, but by 1905 the company was in financial distress, the three brothers had a falling out, and the board of directors, possibly influenced by Henri Junior, ousted both Nicolas and Armand.

The new plant covered almost 60,000 square meters, with 12,000 square meters of manufacturing facilities. Annual production at the new factory, as the bi-weekly Der Waffenschmied wrote in 1910, was 60,000 hunting rifles, 30,000 automatic pistols, 30,000 semi-automatic rifles and 12 million cartridges. Subsequently, the Anciens Etablissements Pieper will manufacture a range of Bayard pocket pistols, the Bergmann-Bayard 1908 pistol, various rifles, shotguns, hunting weapons, submachine guns, revolvers, as well as air rifles after the Second World War, right up to the 1950s. However, this is NOT the story we want to tell, but rather the divergent one of Nicolas Pieper. We will use the patents, advertising and information provided by Waffenschmied magazine to establish a timeline. Based on the assumption that Nicolas Pieper's advertising goes hand in hand with his patents and the introduction of new models of pistols, we believe that we can establish a precise timetable for his work. But a large part of the story has already been documented by our co-author Michel Druart: Bayard: Les hommes, les armes et les machines du Chevalier Pieper & Cie 1859-1957. His book is the foundation on which this article is written. After his ouster from the family business, Nicolas Pieper founded a new company in 1905 under the name Fabrique d'armes automatiques Nicolas Pieper in Houtain Saint-Siméon, in the Liège suburbs. Subsequently, and undoubtedly in precarious conditions, he moved to 292 rue Vivegnis (Liège) before moving to a property near his brother-in-law Auguste Lambrecht at number 42 rue Bonne Nouvelle. During the First World War, from 1914 to 1918, probably due to economic difficulties, Nicolas transferred his business to a property belonging to his brother-in-law at 3-5 Place Bonne Nouvelle in Liège. Nicolas Pieper's goal was to start manufacturing automatic pistols of his invention. In reality, no doubt to feed himself and pay the bills, he also produced rifles and shotguns. It is established that none of his workshops had the capacity for large-scale commercial production. He himself did not have the capital necessary for the development of such an activity. Luckily, at the time of the Etablissements Pieper he had maintained excellent relations with the management of the Austrian Waffenfabrik Steyr. Steyr was to produce certain N. Pieper models under his name and later buy the license for its own manufacture of Pieper’s design. In 1923, Nicolas Pieper opened a "factory" in Paris at 36 rue de la Bastille. It was probably only a business office, possibly coupled with a repair shop for pistols. Very little is known about the activities of this enterprise. It is possible that actual manufacturing was subcontracted and did not take place at this location. The last patent for an automatic pistol was filed in France by Nicolas Pieper in 1923. Finally the very last N. Pieper patent that we were able to locate involved a rifle mechanism, filed in France in 1930; it is noted there that he was a French resident at that time. Nicolas Pieper died in Liège in 1933 at the age of 62. Patents

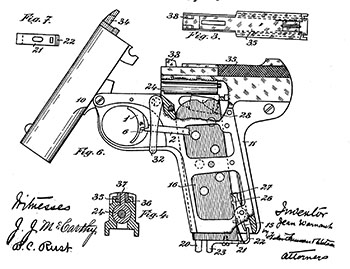

Nicholas Pieper himself began to make new designs derived from the Warnant patent, and immediately filed patents for them. Pieper’s early designs have dismounting (demontant) barrels and slide housings as opposed to the tilting (basculant) designs of Warnant. The earliest design uses screws to retain the barrel and slide housing. German patent 195685 of 1906 describes a means of magazine fixation using a spring activated lever and a magazine baseplate which extends to the rear which we find in virtually all subsequent Pieper pistols.

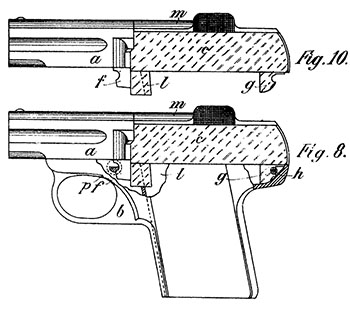

In December 1908, Der Waffenschmied reports that Pieper sold the rights for a pistol, based on the N. Pieper system, to the Austrian Steyr company, and that Steyr had started producing a pistol based on the Pieper design – the Steyr 1909 pistol. In the same year (1908), Pieper filed a patent for a new pistol, where he changed the position of the recoil spring from above the barrel to above the breach block inside the breech housing. The patent claim is that the breech block and main spring are fully enclosed in the breech housing. To make the gun ready to fire the first cartridge must be chambered by tilting the barrel down, since no means was provided to manipulate the breech by hand. However, this gun was never produced. For the sake of brevity we list only the U.S. patents here, but in our timeline for the Nicolas Pieper pistols we provide lists and information about Pieper’s other patents. List of US patents:

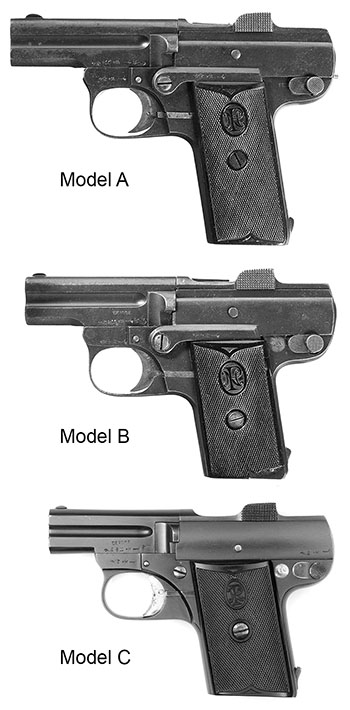

Nicolas Pieper’s Pistols Basically, three types of pistols were manufactured by Nicolas Pieper. The first guns were assembled with screws. Later guns fell into two categories: demontant or basculant (dismantling or tipping) by means of a lever: The first type (demontant) used the lever to release and separate the barrel and breech block housing from the frame. The second type (basculant) used the lever to allow the barrel to be tipped down. To distinguish the models, Nicolas Pieper added, as a prefix to the serial number, the letters A, B, or C, corresponding to the size of the pistol. However, not all pistols were marked in this way, and at the option of manufacturing, new letter designations were added, which does not simplify their identification.

The first productions of Nicolas Pieper after the creation of his new company, Fabrique d’armes automatique Nicolas Pieper, probably started about a year after the liquidation of the Société Anonyme des Etablissements Pieper. The first automatic pistol is not officially dated but most collectors seem to designate it today as the 1907 model. Note however that production and advertising actually started in 1906. Indeed it was in December of this year that Nicolas Pieper published an advertisement in the German biweekly magazine Waffenschmied already offering three different automatic pistols:

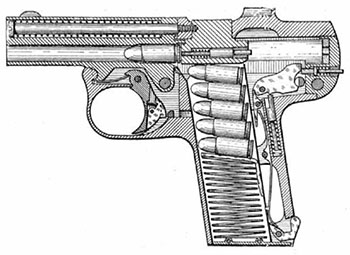

The Model 1907 is essentially based on Warnant’s original design, but without the tilting barrel. Warnant’s patent forms the basis of all of Nicolas Pieper’s pistols, though he continued to modify and perfect the design over the years. The Model 1907 is an unlocked-breech, center-fire pistol with an internal hammer and a recoil spring housed above the barrel. The Models A and B are fitted with a cocked hammer indicator which has not been observed on the Model C. The bolt or breech block is attached to a very thin reciprocating slide that runs in slots cut in top of the breech housing. To cock the pistol and insert a cartridge, the slide is operated using a raised and checkered projection. Into the front of this slide with its dependent breech block is screwed the recoil spring guide rod, which may be unscrewed from the front of the gun. Once the barrel and breech block/slide assembly have been removed from the frame, the breech block may simply be twisted to one side to allow the barrel to be cleaned. The extractor is a flat spring with a hook on the front, mounted flush with the breech block on the right side. The ejector is a protrusion on the left inner wall of the breech housing. The trigger is tensioned by a V-shaped flat spring above the trigger-guard.

There is no mechanism to prevent the gun from firing when the breech is open. Instead, there is a spring-loaded “release mechanism” on the back of the trigger that depresses the transfer bar then pushes past it and can only re-engage the transfer bar after the trigger has been released. In addition, the transfer bar is only pressed forward by the sear to engage the trigger if the hammer is cocked. These first Nicolas Pieper pistols did not have a lever to allow disassembly, but instead utilized screws to fix the breech and barrel assembly to the frame. One screw is behind the trigger. The second screw is at the rear of the grip tang, covered up by the safety lever when in the Fire (FEU) position. When the screw is visible, the gun is in the safe mode. On the Model A and B the top of the recoil spring housing is marked in all-capital sans-serif characters: PISTOLET AUTOMATIQUE N. PIEPER BTE. S.G.D.G.

The grip plates are made of checkered hard rubber with a diamond-shaped notch at top and bottom and an “NP” monogram in an oval at the top. The grip plates are attached to the frame with a single screw on each side. Model C pistols do not have the heavy reinforcement around the front screw, extending over the top of the grip plates.

In late 1907 or early 1908, Pieper introduces a new feature. The frame is identical to the Model 1907, but the front screw is replaced by a keyed pin attached to a locking lever on the left side above the trigger guard. Pieper advertises this feature as allowing disassembly without tools (“demontant”). After turning the lever down, one can lift the breech assembly and barrel from the frame, which facilitates cleaning and maintenance.

In parallel, Pieper also offers the same pistol with a tipping barrel (“basculant”) which brings him back to the original Warnant design. Here, the barrel assembly tips around the axis pin at the front of the gun. By lowering the central release lever, the barrel assembly is disengaged and can be tipped up. We have documented a few Model C pistols with O and P prefixes. The O prefix appears on the demontant version, whereas the P prefix appears on the basculant version. Mötz and Schuy, in the second volume of their book on Austrian pistols, refer to this gun as the Model P. The recoil spring guide rod has a T-shaped extension at its rear end, which engages with a pair of studs at the front of the slide. This differs from the design Pieper sold to Steyr in the same year, which has a hook at the end of the recoil spring guide rod. We do not know the precise details of Pieper’s agreement with Steyr, but it likely included a stipulation that he would not manufacture exactly the same gun. The breech housing of the “basculant” gun is held in place by a single screw at the rear, covered by the safety lever when in the “fire” position, just like the Model 1907. Like the Model 1907, the Model 1908 is marked on the left side of the recoil spring housing in all-capital sans-serif characters as follows: PISTOLET AUTOMATIQUE N. PIEPER BTE. S.G.D.G. Serial number, markings, and grip plates are identical to the Model 1907. The finish is blued with the trigger “in the white” and the transfer bar fire blued. A 1909 advertisement states that the gun is available blued, browned, or nickel plated, as well as engraved or inlaid with gold; and also with rubber, walnut, celluloid, ivory or mother-of-pearl grips. The Model D (Model 1909, 1914, 1919, & 1920)

The rear portion of the transfer bar, which runs on the left side of the gun, is a piece of spring steel, the end of which bears against the sear. The disconnector mechanism is a small bell crank lever , one end of which bears against the hammer spring in such a way that when the hammer is not cocked the lever rotates and presses the end of the transfer bar down, preventing it from engaging the sear. In this way, only when the hammer is cocked can the transfer bar engage the sear. This mechanism is described in U.S. patent 927070 which was filed on 23 November 1908, and which corresponds with a Belgian patent filed by Pieper in May of the same year. Unlike the 1908 patent drawing, there is no crosspiece to support a central grip screw on the Model D. Hence the gun has two grip screws, one at the top and one at the bottom. Safety lever positions are marked in English, SAFE and FIRE. The finish is blued, with the release lever in fire blue, and the trigger and transfer bar “in the white.” A 1909 advertisement states that the gun is available blued, browned, or nickel plated, as well as engraved or inlaid with gold; and also with rubber, walnut, celluloid, ivory or mother-of-pearl grips. Like earlier guns, the 1909 Model D is marked, but on the left side of the breech housing rather than the recoil spring housing, in all-capital sans-serif characters as follows: PISTOLET AUTOMATIQUE N. PIEPER BTE. S.G.D.G. The left side of the barrel is marked with patent numbers in all-capital sans-serif characters: PAT.9379 A/05-25025/06-28177/07 We have documented one 1909 Model D pistol with the second line of patent numbers on the right side of the barrel.

The serial number is found on the right side of the breech housing, the barrel, and on the frame beneath the right grip plate. The number on the recoil housing is preceded by the letter “D.” Grip plates on the Model 1909 are of checkered hard rubber with the NP monogram in an oval at the center. The Model 1914 is rather scarce, as its production was interrupted by the war. We have been unable to locate one for examination. It is marked on the left side of the breech housing in all -capital italic serif characters: PISTOLET AUTOMATIQUE After the war the gun is renamed the Model 1919. The bell crank lever that operates off the hammer spring to disconnect the transfer bar is eliminated, simplifying both production and assembly. Instead, the end of the transfer bar bears against a cut in the grip frame, pushing the transfer bar down and away from the sear when the trigger is pulled. Only when the hammer is cocked and the sear is tensioned in the forward position can the transfer bar engage the sear.

-PISTOLET AUTOMATIQUE- The patent numbers are no longer present on the barrel. On the right side of the breech housing, in all-capital sans-serif characters is stamped: PIEPER PATENT And on the right side of the barrel in front of the serial number is the word DEPOSE, which literally means “deposited” but may be interpreted as “patent filed.” Grip plates on the Model 1919 are of checkered wood. The serial number on the breech housing is no longer preceded by the letter “D.” In 1920 the gun was renamed the Model 1920. The left side of the breech housing is marked in all-capital italic serif characters: PISTOLET AUTOMATIQUE The front sight on the Model 1920 is enlarged slightly and the gripping area on the safety lever becomes circular rather than oval. The end of the transfer bar is redesigned slightly. Right side markings are identical to the Model 1919. Grip plates on the Model 1920 are of checkered horn with the NP monogram in an oval in the middle. The Models AD and BD (1912)

The first advertising we have located is from March 1912 , when Pieper advertising proclaimed his new models as “Neuheit”,” which translates literally as “novelty,” but is perhaps best thought of as an advertising slogan along the line of “brand new!” The new model is another dismountable (demontant) pistol, but the release lever is moved from the middle of the frame to the front. By rotating this lever 180 degrees, the barrel and breech assembly can be lifted from the frame. The rear sight is dovetailed into the top of the slide and is checkered on each side to serve as a gripping surface for retracting the slide.

The Model AD pistols produced prior to the Great War had the same markings as the 1909 Model D, including the patent numbers. The Model AD pistols made after the war are unmarked on the left side, except for the standard Belgian proof marks. The right side of the breech housing behind the ejection port is marked in all-capital italic serif characters: N. PIEPER PATENT The serial number is on the right side of the breech housing, the barrel, and beneath the right grip plate. The grips are of checkered wood. The finish is blued with the trigger and transfer bar “in the white.”

Markings on BD pistols made before the Great War are identical to those on the 1909 Model D. During

We have not documented any BD pistols made after the war, but please write to us if you have one with a high serial number.*

By the end of World War I, designs with the recoil spring over the barrel were beginning to seem somewhat old-fashioned. The Legia is Pieper’s first and only design with the recoil spring beneath the barrel. The gun is a hammer-fired unlocked breech pistol chambered for the 6.35mm Browning cartridge (.25 ACP), with the ejection port on the right side, an external extractor, and a grip safety . The slide is distinguished by two scalloped areas on either side of the top behind the ejection port, and a sighting groove down the center. Like the Model BD, the Legia was available with an extended “reserve” magazine holding ten cartridges. According to the advertising brochure, the gun came with a tool for removing the barrel. There are two variations of the Legia. First Variation Legia

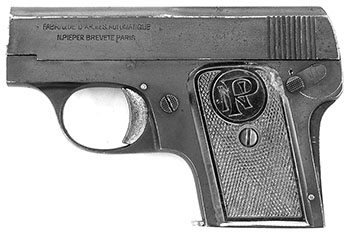

N. PIEPER PATENT The grip plates appear to be of checkered hard rubber with a single screw in the middle and the words “N. Pieper Brevete” in a circle at the top. An illustration from an advertising brochure also shows grip plates with the Liège perron, the letters “LG” and the words “LEGIA PISTOL,” and we have photographs of just such a pistol with the following slide legend in sans-serif characters: LEGIA PISTOL We also have an illustration of a Legia pistol with the same marking in all-capital serife characters: LEGIA PISTOL Only a single specimen we have documented is actually marked with the name “Legia,” other than advertising illustrations, though some have grip plates with the word Legia. Of the two advertisements we have, neither refers to the gun as the “Legia” but in both cases as “Pistolet N. Pieper.” Second Variation Legia A second version appears on Alain Daubress’s site littlegun.be, at the bottom of the page. This gun has a checkered button behind the trigger on the left side, which is the magazine release, and a manual safety lever on the left grip tang. A button on the right side serves to lock the recoil spring in its compressed position, in order to disassemble the pistol. What looks like an external transfer bar on the right side is actually part of the magazine release mechanism. The grip plates are of wood with a brass medallion with the NP monogram in the center, held in place by two grip screws. The slide is marked on the left side in all-capital italic sans-serif characters as follows: N. PIEPER PATENT

Two other known specimens with the checkered button on the left side have checkered hard rubber grips with a single screw in the center, but with the “NP” monogram in a circle at the top, a different style of manual safety lever, and the following inscription in all-capital sans-serif characters: FABRIQUE D’ARMES AUTOMATIQUE

Some sources have expressed doubts about whether the Legia pistol was made in France or Belgium, but the first variation guns have legitimate Belgian proof marks, so we tentatively conclude that they were made or at least prooved in Belgium. The few second variant guns that have been documented do not have proof marks. The highest serial number we have documented is 3905. If you have a Legia pistol, please write to us.*

Pistolet Basculant

The gun is stamped on the left side of the breech housing in all-capital italic serif characters as follows: PISTOLET BASCULANT The grip plates appear to be of checkered hard rubber with the NP monogram in an oval surrounded by the words PISTOLET BASCULANT. This is the only such pistol we have documented thus far, but there are probably more. Prototypes Model 1908 Basculant Prototype We have in our possession a 6.35mm Model 1908 basculant pistol with a method of fixing the recoil spring guide rod to the slide that differs from others we have observed. The gun has the usual inscription on the left side of the barrel, and proof marks, but no serial number. A number was stamped beneath the right grip plate, but was canceled out. We believe this pistol may have been a prototype.

.45 Caliber Prototype In an attempt

N. PIEPER PATENT According to Edward Scott Meadows, in his book U.S. Military Automatic Pistols, 1894-1920, it was received by the Ordnance Department on 10 April 1911. It was examined and tested and a report was submitted on 26 April indicating that the gun has an unlocked breech, “...a feature considered very undesirable,” no true disconnector, no external hammer to allow for quick cocking, and no extractor, so if a shell gets stuck it can only be removed by hand. The report also states: “The pistol has an objectionable number of screws and flat springs and it is the opinion of the Board that the construction is too weak to withstand the requirements of a service pistol.”

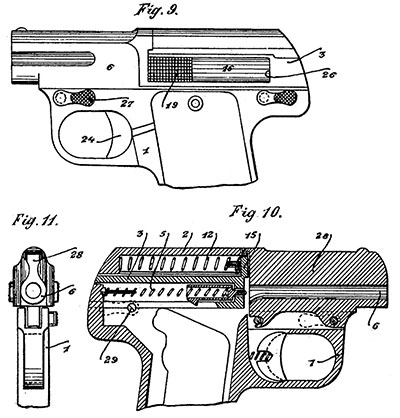

On 27 December 1913, Nicolas Pieper filed for a patent (Belgian patent № 263468) on several designs for demontant pistols, including one with a bolt that moves in a slot in the upper recoil housing, similar to the Clement pistol of 1903, but with a lever at the front that allows quick removal of the barrel and bolt. Unlike the Clement design, however, this design has the recoil spring in the housing above the bolt instead of above the barrel.

Nicolas clearly had production in mind, because he also filed the patent in Austria (№ 81433), Spain (№ 58456), France (№ 473121), the Netherlands (№ 3806), Great Britain (№ 134777), and the United States (№1427413) between 1914 and 1919. The design was never manufactured commercially, probably due to the intervention of World War I, but a prototype has recently surfaced in South America. The prototype features Nicolas’ rear-mounted magazine release with the magazine baseplate that extends to the rear.

* Write to edbuffaloe@unblinkingeye.com. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2020 by Stefan Klein, Michel Druart & Ed Buffaloe. All rights reserved. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||