|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Franz Jäger’s Self Loading Pistol By Ron Schappaugh and Dr. Stefan Klein

The story of the Jäger pistol is the story of necessity being an angel of invention. Franz Jäger

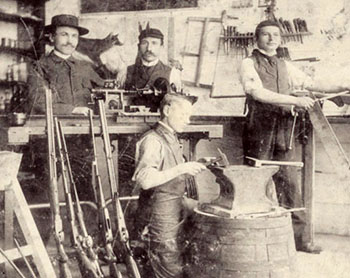

In 1902, Franz and his new family left New York for Liege, Belgium. After a year, they moved to Suhl to find qualified craftsmen that could execute the shotguns he envisioned. The custom gun shop he

Everything changed on August 1, 1914 when Germany declared war on Russia and entered World War I. Shortly thereafter General von Falkenhayn, Kaiser Wilhelm’s Minister of War, decreed: “For the duration of hostilities all the hunting and sporting weapons factories are to be obliged to produce for military needs." Jäger lacked a design for a military weapon and also the milling and broaching machines necessary to make one. He was faced with closing his business and laying off his workers including his three brothers, Karl, Paul and Reinhold. The company desperately needed a military firearm design that its workers could make using existing equipment. Behold the angel. From his experience

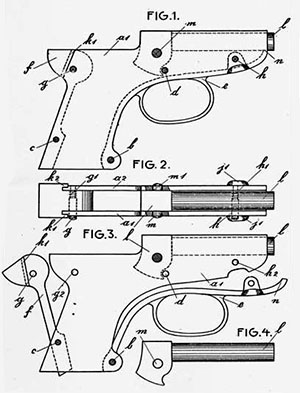

Jäger applied for a German patent on November 30, 1914, which was rejected on February 8, 1916, on the grounds that there was nothing unique about the design. Jäger’s claim that his design with a frame consisting of side-plates and spacers, which are connected by screws was dismissed as “differing from existing methods by only simple structural measures, which are within the ordinary skill of the art.” The rejection of his application for a US patent noted that Jäger’s claimed ideas were already covered by Patent Number 1,059,405 for the Sprague Folding Pistol. The German Army’s evaluation was equally unenthusiastic, dismissing his design as “only from sheet metal.” But, the army approved the Jäger along with 26 other pistols as acceptable for private purchase by military officers. Officers reportedly purchased approximately 2,000 pistols for the price of 33 marks. The one party impressed by the design and eager to manufacture the pistol was the Krieghoff company, also located in Suhl. They may even have assisted with the patent costs, but once the patent was denied they lost interest.

Production started in October 1914 and ended in 1917. In three years, approximately 13,000 pistols were produced. During the war, the factory

also designed and produced a simple flare pistol. As the war progressed, Jäger’s brother Paul joined the army and was killed in 1914, and his brother

Reinhold was drafted. In the spring of 1916, Franz Jäger himself was drafted and served in Infantry Regiment 71 in Erfurt, leaving only Karl, with little business experience, in charge.

The Jäger pistol deserves its place in firearms history not because of a new innovative action; rather, what is noteworthy is that the design introduced a new level of modern industrial manufacturing techniques into the production of firearms. While these techniques were belittled at the time, 30 years later they were widely used on weapons like the MP40, the Sten gun, and later on the AK-47. While most chronicles of the Jäger pistol state that parts were made from stamped and shaped sheet metal, this was not the case. The pistol’s flat side-plates were made from 2.7mm (.106 inch) steel, which was far too thick to shape by stamping. Instead, the flat side-plates were die-cut, i.e., punched. (Note: some sources report the side-plate thickness as 2.4 or 2.5mm.) While its appearance was quite modern, the quality of finish was far below that of Jäger shotguns and rifles

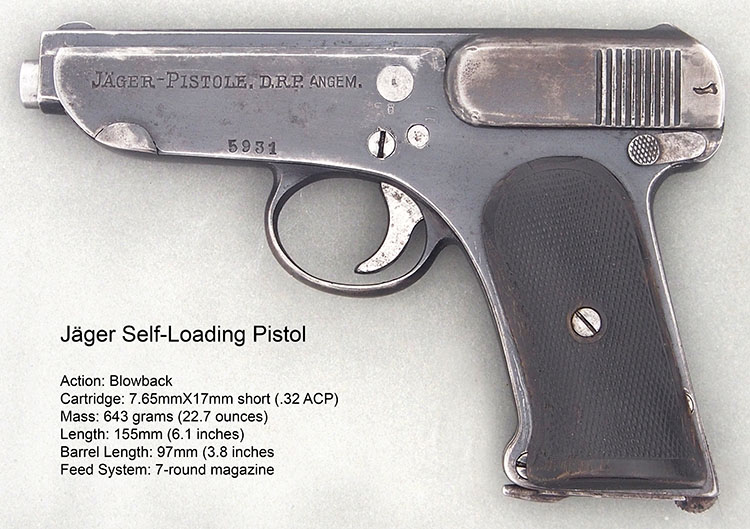

The Jäger pistol has a simple striker fired, blowback action with the recoil spring surrounding the barrel, typical of many 7.65mm pistols of the era. The revolutionary feature that Jäger introduced was a frame composed of four parts. The two die-cut flat side-plates required only minimal milling on the inside surfaces. The forged-steel front and back straps were also finished with limited machining. They are held between the side-plates by three screws and two spring loaded pins. The front strap, which extends to the muzzle, includes the trigger guard and holds the trigger and its spring. The back strap contains the lockwork (sear, sear spring and safety) and the butt-mounted magazine release and its spring. This self-contained removable lockwork concept was seen again with the Tokarev TT-30 and the two French 1935 pistols. The trigger bar, which also serves as the disconnector, slides in a diagonal recess milled into the right side-plate. The manual safety blocks the movement of the sear when it is engaged by rotating rearward. There is no magazine safety and no means to hold the action open.

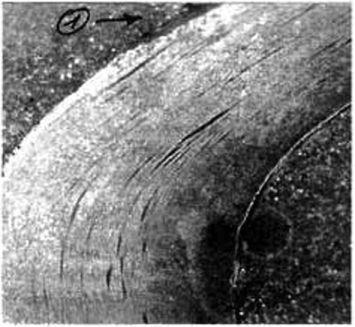

The barrel has a rectangular chamber block with an integral feed ramp. The two variations of the pistol have different combinations of round studs and pins on each side of the chamber block. They fit precisely into holes punched in the side-plates and align the barrel and frame. The barrel has four right-twist lands. Interestingly, the six pistols with serial numbers ranging from 3889 to 9102 reported in Mathews’ Firearms Identification have land widths and twist rates that vary significantly. The breech block, which houses the extractor, firing pin and the firing pin spring, is one of the few parts that required precise machining. The breech block sits loosely in the slide and rests on the top edge of the slide-plates. A transverse groove on the top of the breech block engages with the bottom half of a large transverse pin through the slide. The ejector is attached to the inside of the left side-plate by a “T” shaped pin on the early pistols and by a large flat head screw on later pistols.

The interior parts and surfaces were typically roughly finished, with coarse milling and filing marks as shown in the photograph above. However, considerable attention was paid to the exterior appearance. All of the small transverse pins through the slide and the large flat head screw holding the ejector to the left side-plate were carefully fitted before the slide and the side-plates were polished and finished. In most cases the pins are difficult to see, adding to the gun’s sleek look. All parts were hot-salt blue finished except for the barrel and trigger. Magazines Two types of magazines were used. The most common has a tapered steel spur attached to the surface of the base-plate extending to the front. The spur was for depressing the front and back strap dimpled pins when field stripping. The bottom of the front strap was grooved to provide clearance for the spur. Some early pistols had flat base-plate magazines that extend beyond the magazine box front. Pistols issued with flat

Grips All factory grips were horn; most were black but a few dark brown grips have been observed. Some early grips have a letter scratched on the back side and some later grips have a stamped number. These are believed to be inspectors marks. There are no known factory issued wood grips. Accessories Little has been written about accessories for the Jäger pistol, perhaps because there were none. In 1916, Jäger was awarded a patent for a pistol holster; but, it is not known if this was a holster for his pistol or if it was ever manufactured. Jäger pistols came with a small folded card containing field stripping instructions.

There are no universally accepted variations for the Jäger pistol even among European collectors. This may be because little has been written about the Jäger, compared to other pistols. A database with information on 228 Jäger pistols from a variety of sources both in the United States and Europe, primarily Germany, was used for this analysis of variations. Sources include magazine articles and books, as well as auction photographs and other online image sources. In most cases the information is limited to serial number, one versus two pins, commercial versus military, and spur versus flat base-plate magazine. The lowest serial number recorded in the database is 1 and the highest is 12606. The distribution of the 228 pistols is relatively uniform across this range. There are ten gaps of over 200 guns with the largest being 621 guns (11299 to 11920). Of the pistols recorded, 72 are First Variation and 156 are Second Variation. Assuming a total of 13,000 pistols were manufactured, the 228 pistols are 1.8 percent of the total - not a very significant sample from which to draw conclusions. Nevertheless, this is what was available to work with. Variations The collected information supports two significant variations, each containing a large number of pistols, with readily observable differences and distinct serial number ranges. There is one sub -variant with less significant differences and a random distribution. Finally, there are several anomalies involving a very small number of pistols.

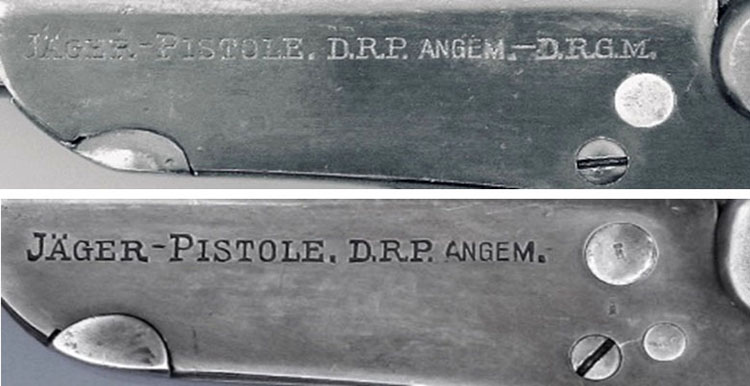

First and Second Variation differences are highlighted in the photograph above. The most obvious are in group #1. Both have a screw which secures the side-plates. The First Variation pistol has a large pin permanently fixed to the chamber block that projects through the slide-plate at 1:00 o’clock to the screw head. On Second Variation pistols, barrel studs located closer to the top of the side-plate replace the large pin. These studs are an integral part of the chamber block. A smaller also permanently fixed pin passes through the chamber block, at 2 o’clock to screw head. This pin provides additional stability to the barrel. Change #2 thickens the trigger slightly, and as #3 shows, the Second Variation example has a slightly wider grip contour. At #4 the frame inscription was changed as described below. The serial number location #5 was moved from the lower front of the right side-plate to the opposite side. This change occurred later than the other changes in the transition. The Second Variation example in the photograph still has its serial number, 5390, on the right side. The profile and thickness of the nubs #6 on the front strap were changed to facilitate field stripping . Slight changes to the profile of the side-plates are visible at #7 and #10; the purpose is not obvious. An additional pin #8 was added to Second Variation pistols to secure the slide front closure piece, and the height of the front sight #9 was lowered. The change in the front profile of the slide grip area is visible at #11. The method of securing the slide rear closure piece #12 underwent several changes. Except for a limited number of very early pistols, both variations have two fasteners. A small, often difficult to see, pin is located high on the slide behind the grip serrations. The other fastener is a screw for the First Variation and a “rivet” on the Second Variation. The change from a screw to a rivet also occurred later, at least as late as serial number 6205. Perhaps it never changed and high-head screws were simply ground flat before the slides were finished. Many examples in the 9000 and 10000 range are found with faint marks of a screw slot still visible. The numerous small changes made as part of the Second Variation may reflect limited testing before production of the pistol began. Also, the army may have required changes before approving the Jäger for officer purchases. Flat Base-Plate Magazine Sub-Variant pistols are identical to the First Variation with the exception of the magazines which do not have a spur, and the bottom of the front straps which do not have a groove for the spur. Seventeen pistols, 24 percent of those recorded in the First Variation range, are without a groove with 4512 the highest serial number. No Second Variation pistols have been noted without the front strap groove. Military Marked pistols were privately purchased by officers and marked with the military acceptance stamps described below. Although it has been widely reported that 2,000 pistols went to the military, the source of this information is unknown. Based on analysis of the pistols recorded , the actual number may be much larger. With one exception (11095), all military marked pistols recorded are relatively evenly distributed across the range from 5167 (the first noted Second Variation pistol) to 9638. Of those noted between 5167 and 9638, 70 percent are military marked. Applying 70 percent to all 4,471 pistol in this range suggests more than 3,000 military marked pistols. However, this rationale may be flawed because there appear to be several block purchases. Anomalies

Markings

The Jäger pistol has a very solid feel. The thick side-plates make for a very rigid frame and barrel alignment which contribute to excellent accuracy. Twenty-one rounds (three magazines) of Remington .32 Auto, 71 gr. ammunition were fired at a distance of seven yards using a rest. The smallest of the three groups was 1.6 inches (41mm) and the largest was 2.0 inches (51mm). There was one failure-to-eject malfunction. That said, there are some aspects of the design that detract from the shooting experience:

Disassembly is unusual but straightforward.

Reassemble in reverse order with the following suggestions.

Questions remain for collectors to resolve by examining their pistols and researching German Army documents:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2020 by Ron Schappaugh and Dr. Stefan Klein. All rights reserved. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||