|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Heckler & Koch Model 4 Pistol

The HK4 – Today the name Heckler & Koch is synonymous with auto pistols and assault rifles for police and military use, but this was not always the case. This article will take a look at the origins of the Heckler & Koch Company and its first production pistol, the Model 4 (HK4) which was released in 1968. The name was chosen because the pistol was available with four interchangeable barrel and spring kits: .22 Long Rifle, 6.35 mm Browning, 7.65mm Browning and 9mm Browning Short.

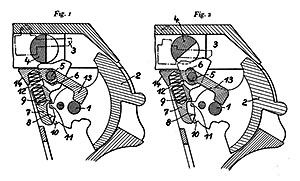

One of the owners of the Heckler & Koch Company, Alex Seidel, had been the primary design engineer behind the Mauser HSc (the Hahn- Selbstladespannpistole, Ausführung c) before World War II. So it is not surprising that the HK4 is closely related to the Mauser HSc. The idea of interchangeable barrels was not new either. In 1934 the August Menz Company had released the “PB Spezial” which was issued with interchangeable barrels in 9mm short, 7.65mm Browning, .22 centerfire and 4mm. History of the Heckler & Koch Company

According to Weaver, Speed, and Schmid, in their book Mauser Pistolen: “Mauser-Werke AG, Oberndorf was targeted and bombed by the Allies on February 22, 1945. Physical damage to the facility was considered light, but the attack did serve to cripple the firm’s power plant...” After the war, the Allied Powers agreed that all weapons facilities in Germany were to be demolished, but the French were desperate for weapons for their new war in Indochina and their own infrastructure had been badly degraded, so they put the Mauser facility back into production through 1946, and even after that time, as they were shipping major machinery back to France, some arms-making activity may have continued. Mauser had been the most important employer in the region and for many families it had been their only source of income. After the factory was closed, most ex-employees were completely out of work. Three former Mauser engineers, Edmund Heckler, Alex Seidel, and Theodor Koch, wished to support economic development and provide jobs. The obvious solution was to start a metal fabrication company, since they already had a trained workforce. One on-line source states that the three sneaked into the Mauser factory to rescue much-needed equipment before it could be destroyed or removed, though Manfred Kersten states that the three negotiated with the French before the factory was demolished. The official company history on the Heckler & Koch website simply says they “...saved what they could from the ruins, thus laying the foundation for what was to become Heckler & Koch.” The core of the new company was the Ingenieurbüro Heckler (Engineering Office Heckler) which Edmund Heckler founded in 1948. Heckler and Theodor Koch became partners and renamed Heckler’s company Heckler & Koch GmbH on 28 December 1949. The H&K company website states that, “Alex Seidel joined the team in 1949.” Why his name is not part of the company name is not explained.

Heckler & Koch enjoyed rapid economic success and in 1952 new factory buildings were erected. The company then focused on manufacturing gauges and specialized tooling and in 1955 it began production of military equipment. The company website states, justifiably, that Heckler & Koch helped rebuild Germany after it had been mostly destroyed during the war. They certainly had a major impact on the prosperity and economic growth of their region. In 1955 Germany joined NATO and the German Bundeswehr (Federal Defense Service) was founded. Soon there was a demand for a new assault rifle which should be produced on German soil. In 1958 Heckler & Koch was chosen to produce the G3 rifle. Unfortunately Edmund Heckler did not live to see the great success of this product, as he died in 1960. A few years later Heckler & Koch decided to produce a service pistol. Alex Seidel had been the primary engineer involved in the production of the Mauser HSc pistol, so the HSc design formed the basis for the HK4. The project originated in 1966 and the HK4 went to market in 1968. The Heckler & Koch Model 4 (HK4) The HK4 is a blow-back operated unlocked-breech semiautomatic pistol with a double-action trigger and an external hammer. Its name is derived from the tool-free interchangeability of the four barrels in calibers 9mm Browning Short, 7.65mm Browning, 6.35mm Browning and .22 Long Rifle. The gun consists of four main components: slide, barrel and recoil spring assembly, frame, and magazine.

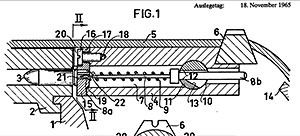

The barrels have six grooves with a right-hand twist. Early barrels in 9mm short and .22 long rifle have linear grooves in the chamber, four in the 9mm and eight in the .22. In .22 these grooves extend the full length of the chamber. When the round is fired the hot gases flow into the grooves and the case “swims” in the chamber. So Heckler & Koch was able to compensate for different case materials and qualities. In the 9mm short barrel the grooves do not extend the full length of the chamber and are deeper at the center. In this case the pressure of the discharged shot forces the brass of the case to flow into the groove and thereby delays the opening of the breech. In theory these grooves allow for the elimination of a heavy slide and an overly-stiff recoil spring. This is not a new principle and was first used by the Fritz Mann Company in the Model 1920 Mann Pistol which had an annular groove in the chamber into which the cartridge expanded. The chamber grooves for both 9mm and .22 were eliminated in later production barrels, and so perhaps were not as necessary as the designer originally thought. The strength of each recoil spring is specifically adjusted to the respective caliber. Hence each spring is fixed to its respective barrel so they do not get mixed up. The frame is made of pressure cast aluminum, which is surface hardened. To compensate for the stiff recoil of the light slide, a buffer plate is attached to the slide stop at the front of the frame. Early buffer plates consist of a piece of steel sheet with a plastic element on the front. Late buffers have a piece of sheet steel on both sides. Grips are made of black or brown plastic and are attached to the frame from the back with a single screw. The magazines hold eight rounds, except for the 9mm short which holds seven. The magazine bodies for the large calibers are all quite similar, though the .22 magazine has a distinctive look. Each magazine is inscribed with its caliber to prevent confusion.

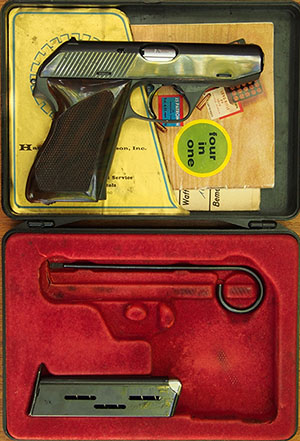

The safety lever on the left side of the frame blocks the firing pin and pushes it down out of reach of the hammer. In the safe position the firing pin is additionally locked in position. The hammer is designed in such a way that, whether cocked or not, no opening is left above or below it into which dirt or foreign matter might enter. The HK4 came in a black plastic box with a green or red plastic inlay. We have also seen a few black paper boxes. Early pistols had a very simple cleaning rod, one end of which formed a screwdriver blade. Later pistols came with a red plastic screwdriver which contained a cleaning kit.

A later manual shows a late pistol which still has the early grips. The manual underwent some changes and also describes the new screwdriver. Perhaps there are more variants we have yet to discover. However, why do we mention this? The most interesting point is that the early cutaway drawing shows minor technical changes which were not mentioned in all the sources we have. We see differences in the length of the screw of the breech plate, the form of the striker, the hammer assembly, the magazine release, and the magazine which has a pin inside which limits the number of cartridges, etc. However, when we examine our pistols we realize that all our guns are as shown in the late manual. So, perhaps by accident, Heckler & Koch used an obsolete or incorrect cutaway drawing to illustrate the first HK4 manual. Handling

Early guns have a very rough and heavy double action trigger pull in the vicinity of 9 kilograms, or about 20 pounds. The single action trigger pull is much lighter at about 1.7 kilograms, or about 4 pounds. According to George C. Nonte, writing in 1977, the later guns have a much improved double action trigger pull, though he still maintained that it was not as good as the Mauser HSc. Disassembly

To change the HK4 from centerfire to rimfire:

Evaluation

At the range, shooting one of the early HK4 pistols, we found the gun reasonably accurate in single-action mode--certainly suitable for self defense. Using the double-action, we were lucky if we hit the target. The sights are quite small and difficult to see. One of us found that the small spur of the hammer pinches the web if his hand during recoil. We experienced feeding problems with both hollow point and hardball ammunition in the 9mm Short (.380) caliber--this may be due to a weakened magazine spring. The gun is 45 years old and we do not know if it was stored with ammunition in the magazine. Patents: Some patents are specific to the Mauser HSc, but may also apply to the HK4:

Another patent related to the HSc was US2107359, granted to Ernst Altenberger for the HSc barrel retention mechanism. This patent was not utilized in the HK4, which used a redesigned latch that served the same function. There are two patents specific to the HK4:

Variants There are two primary variants. The First Variant has 18 shallow flat-bottomed slide serrations at the rear, over the grips. The grips are of brown checkered plastic with a slightly raised thumb rest on the left side. The front of the slide is stamped with a stylized Mod HK4. The three-line inscription, in all capital sans-serif characters, reads: HECKLER & KOCH GMBH The Second Variant has a metal plate fixed to the slide which contains the inscription and serrations, such that the serrations are forward of the grips. Some have brown grips like the first variant, but later black plastic grips were provided with a slightly different design. The stylized Mod HK4 stamp has been moved to the rear of the slide, behind the safety lever. The two-line inscription on the cover plate, in all capital sans-serif characters, reads: HECKLER & KOCH GMBH The right side of the slide is unmarked. The serial number is on the underside of the frame in front of the trigger guard. Early magazines did not have a magazine shoe. Later this was introduced for the customs police and eventually became available on the civilian market.

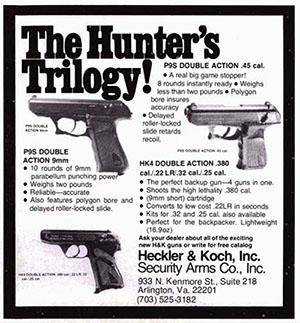

In 1971 H&R imported a special edition of the HK4 (second variant) to commemorate the 100th anniversary of the company (serial numbers HR00001 to HR08700). On this version of the HK4, the nameplate contained the following inscription: Harrington & Richardson Inc. To the right of the inscription was the circular H&R logo with 1871 to the left and 1971 to the right. Harrington & Richardson delivered the HK 4 to customers as a standard two-box set in .380 ACP and .22 LR. The first 2000 guns, serial numbers HR00001 to HR02000, came with a gold trigger and name plate in a red velvet-lined wood presentation case with extra barrel and screwdriver. The HK4 with serial numbers above HR02000 have the standard black nameplate and trigger. A very limited number of four caliber sets were also imported by H&R and are much sought after by collectors. Additionally, we find engraved presentation pistols in very small numbers. In the year 1974 Heckler & Koch sold 555 second variant pistols to the police of West Berlin. This was a little difficult because there were still some Allied restrictions on gun sales. So Heckler & Koch shipped the guns to the French MAS company (Manufacture des Armes de St. Etienne). The pistols have an MAS inscription and French proof marks, and are fitted with black grips. These pistols run from serial 51,566 to 52,120. The slide inscription on the left side reads: MANUFACTURE NATIONALE D’ARMES According to George C. Nonte, eventually H&R’s policy on importing guns changed and the HK4 was dropped. This probably happened sometime in 1974, as the HK4 is still listed as imported by H&R in the 1974 Gun Digest. Security Arms of Arlington, Virginia had been importing other Heckler & Koch pistols, so they took up the HK4. An advertisement from the September/October issue of American Handgunner shows three H&K pistols and lists both company names: Heckler & Koch, Inc. and Security Arms Co., Inc., with the address in Arlington Virginia. HK4 pistols from this period are marked on the right side of the slide: SACO ARL VA or SACO ARL VA 22201 and later HK INC ARL VA 22201 or HK INC Va

HK CHANTILLY Va Jürgen Schönbeck reports that Heckler & Koch produced 38,200 pistols between 1968 and 1984 [3]. 25,800 were sold on the civilian market. Serial numbers for these civilian guns run from 10,001 to 35,800. He also reports that the German Custom Police (Zoll) received 12,400 pistols in 7.65mm Browning between 1970 and 1974 and that some of these pistols came with .22 long rifle barrel sets for training. Serial numbers run from 40,001 to 52,400. However, a certain number of these guns were later exported to the US. They have the HK CHANTILLY Va inscription on the right side and show the word “BUND” on the frame clearly indicating that the guns were made for the German Government. There were also some engraved presentation pistols, though we have few details about them. Heckler & Koch always claimed that the production of the HK4 was very cost efficient due to the deep-drawing process of the slide. Indeed the pricing of the HK4 was quite interesting. 1968 an HK4 in 7.65m browning cost 187 Deutsche Mark (DM). A Walther PPK cost 280 DM, so it was 50% more expensive. A Mauser HSc cost 240 DM in 1969. Barrel sets for the HK4 were 50 DM each Summary The HK4 was the first step the company made in the self-loading pistol market. It brought the pre-war know-how of the Mauser engineers and staff together with the modern production techniques developed by H&K. The interchangeable barrels were an interesting marketing technique. August Menz had also tried to compete against the Walther PPK with his PB Spezial with interchangeable barrels, and H&K tried the same thing 35 years later. Ultimately both failed, although Heckler & Koch went on to become one of the premier weapon-makers of Europe. Once other H&K pistols in larger calibers were in regular production, the HK4 was phased out. So the HK4 was, with the exception of the German Zoll and the Berlin Police, not very successful as a service pistol. Though it was moderately priced, production numbers did not approach the levels of the Walther PPK. By the end of production in 1984 it had to compete with modern self-defense and service pistols such as the Glock. The Heckler & Koch Model 4 may be considered one of the last dinosaurs of the blow-back era. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2016 by Stefan Klein and Ed Buffaloe. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||