|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Reducing Trigger Pull on Colt The problem today is it is almost impossible to find a good gunsmith in the large metropolitan areas of the U.S., and if you do find one he probably has a wait time of six months to a year. I have been reduced to teaching myself how to work on my own revolvers. Here is what I’ve learned about the Colts. I found an excellent article on the Colt Fever website about gunsmithing Colt revolvers. You may want to read it before you proceed any further. A brief quote is to the point: “...the old style Colt [double] action revolvers are complex mechanisms from another century. Virtually every internal part was hand fitted at the factory by Master assemblers with years of training and experience. Unlike automatic pistols, almost no revolver parts can be simply dropped in.” This certainly gives one pause. The author further explains that most parts have at least two functions and it is hard to modify one function without affecting the other. So be very careful. The best you can do is to polish the surfaces of the trigger, the hammer, and the hand and rebound lever so they work smoothly against each other and against the sideplate. Do not remove substantial amounts of metal--just polish the surfaces. Leave the rest to the professionals--the problem being that there is hardly anyone left who still knows how to work on Colts.

The next article I found was an old one by Skeeter Skelton from a 1968 issue of Shooting Times, wherein he explains that all you need to do to reduce the trigger pull on a Colt is insert a steel rod between the arms of the V-shaped mainspring and cock the hammer. This bends the top arm of the spring downward over the rod and reduces the tension it places on the hammer. Here is a direct quote from Skeeter’s article: Diameter of the rod used varies with individual springs. Start with one about 1/16” in thickness. If the bend it causes is not sufficient, gradually increase the diameter of the rod used until the results you want are obtained. Too much bending will result in a spring so weak as to cause poor ignition or misfires, and you can, of course, use a rod so thick as to break the spring. A ¼” rod is the largest I have ever found necessary to produce good results on large frame Colt double actions, and it would be too much for the daintier models, such as the Detective Special. If your bent spring has been overly weakened, it is not difficult to remove it from the gun and carefully straighten it in a vise. Excessive working of the metal is to be avoided and it is better to use a little thought and get things right the first time.

My Experience with My Colts

Secondly, I have an old Colt Detective Special with a three-inch barrel that often failed to ignite primers when fired double-action. Apparently, someone had tried to improve the trigger and had gone a bit too far, just as Skeeter warns not to do. I measured the single-action pull with my new gauge and it measured 3.2 pounds. The double-action trigger pull was 8.8 pounds. So I realized that the minimum single-action trigger pulls given by Kuhnhausen are in some cases theoretical. The optimal single-action pull, at least for D-frame guns like the Detective Special and Agent is going to be somewhere around 4 pounds. For the Detective Special, rather than try to bend the spring back, I thought it would be safer to simply order a new one. Numrich carries springs for virtually every Colt ever made, and I had mine in about a week. After installation the single-action trigger pull is 3.6 pounds and the double-action pull is 10.6 pounds. The gun is perfectly reliable now and I am very happy with it. Using the knowledge I gained from the first two guns, I decided to work on an old .32 Colt Pocket Positive. The single-action was about 5.2 pounds and the double-action pull measured 12.4 pounds. I removed the grips of the Pocket Positive and inserted the shank of a 1/16 inch drill bit between the arms of the V-spring and cocked the hammer. When this didn’t do much I moved to a 3/32 inch bit, then on to a 1/8 inch, a 5/32 inch, and finally an 11/64 inch. The result was that the single action broke at 4.8 pounds and the double-action at 11 pounds. After considerable hesitation, I finally tried a 3/16 inch bit. I could barely get the gun to cock. The result didn’t change the single-action pull much at all--it is still about 4.6 pounds--but the double-action trigger pull is now a very reasonable 9.2 pounds.

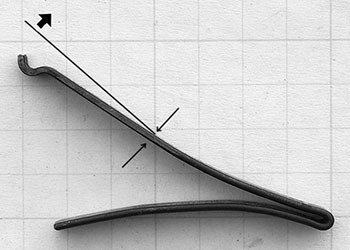

If you need to increase the strength of the spring, you will have to take the spring out of the gun, which means you will have to remove the side plate. If you are not mechanically inclined, do not attempt this--take it to a gunsmith. That being said, if you have a modicum of mechanical knowledge and use a little care there is no reason you can’t do this as well. You must use screwdrivers designed for gunsmithing with hollow ground tips--otherwise you will ruin the screws and reduce the value of your gun. Remove the grip plates and carefully remove the screws that secure the side plate. Keep track of which screw goes where. With the wooden handle of a hammer or screwdriver, rap the grip frame sharply several times to separate the side plate from the frame. Hold the cylinder release with your thumb or finger so it doesn’t fall off--this prevents loss of the tiny spring that tensions it. Take great care not to drop the side plate--if it is deformed even slightly it will not go back on the frame. Be careful handling the gun with the side plate off. Using a pair of good needlenose pliers, squeeze the two arms of the V-spring, disentangle the tip of the upper arm from the hammer stirrup, and carefully remove the spring. (I use needlenose with the gripping surface ground almost smooth, so as not to scratch the spring.) Put the spring in a vise and bend it very slightly upward as shown in the diagram, and reinstall in the gun. Test for single -action hammer pull (I recommend putting the side plate back on for testing). Adjust further as necessary. Too much bending of the spring will destroy its temper and it will have to be replaced. To reinstall the side-plate, make sure the rear portion of the latch pin is standing up straight, as it must fit into a hole on the back of the cylinder release. Squeeze the cylinder release so that the front portion is even with the edge of the side plate and carefully press the side plate onto the frame. Do not force it--it should install very smoothly with very little force. Reinstall the sideplate screws and tighten them carefully. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2016 by Ed Buffaloe. All rights reserved. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||