|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The First .45 Auto: by Ed Buffaloe The Cartridge In 1903 Colt’s experimented with a .41 caliber version of the 1902 Military Model, using a rimless cartridge based on the existing .41 Long Colt. But the powerful .41 cartridge sheared barrel links and pins, and the project was abandoned. Meanwhile, the Army was clearly moving toward mandating the use of a larger caliber cartridge. On 16 October 1903 the Ordnance Department of the U.S. Army convened a board of two men, Capt. John T. Thompson, Ordnance Department, and Maj. Louis A. La Garde, Medical Corps, to determine a minimum handgun caliber for use by the U.S. military. According to Potocki, they had probably completed their tests on cadavers before Thanksgiving of that year. John Thompson served as an inspector during the earlier testing of the 1900 and 1902 Colt Automatic Pistols and had well-established contacts with the Colt’s Patent Fire Arms Manufacturing Company. Potocki believes that Thompson notified Colt’s early on that he and La Garde were leaning toward recommending .45 as the minimum caliber for a military pistol. Hence it was that as early as February of 1904 (a month before the Thompson-La Garde Report was submitted to the Ordnance Department) the Union Metallic Cartridge Company (U.M.C.) ledger states that they had received “figures for the proposed ctgs.”, meaning the caliber, weight and desired velocity of bullet.

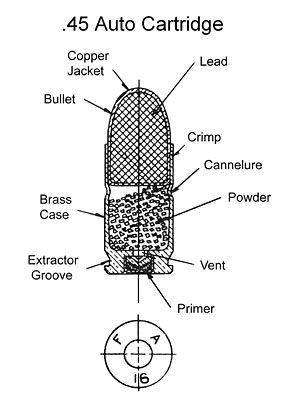

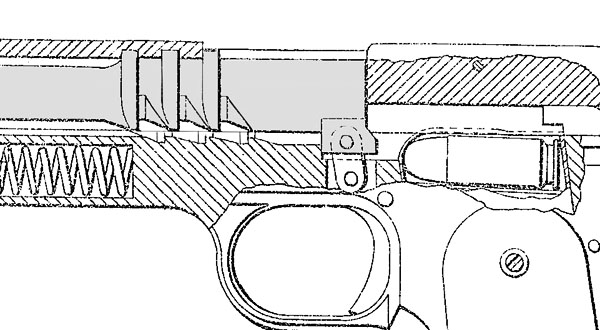

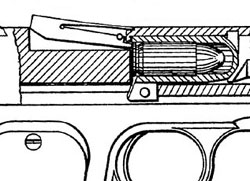

The old .45 Long Colt cartridge had needed a long case because a considerable amount of black powder was required to propel its 250 grain bullet. But a much smaller charge of smokeless powder would give the same velocity, so a shorter case could be used for the auto cartridge and still have great stopping power. The weight of the bullet was reduced to 200 grains to provide better accuracy. Colt’s has been reported to have been working with both U.M.C. and Winchester to come up with a cartridge suitable for the gun. But I think it more likely that they were working primarily with U.M.C., since U.M.C. had previously designed many cartridges for Colt revolvers, including the .45 Long Colt. We know from the U.M.C. ledger that as early as April of 1905 U.M.C. was producing true rimless cartridges for Colt’s to test with--with 200 grain bullets, just over 5 grains of Bullseye powder, and a cartridge length identical to that of the .38 auto. Further refinements of the cartridge continued well after the first .45 auto pistols were shipped in December of 1905. In April of 1906 the anvil was raised to improve reliability of primer ignition. In March of 1908, after extensive government testing of the Model 1907, the bevel of the extractor groove was made longer to improve reliability of extraction. The Colt Model 1905 Automatic Pistol While development of the .45 Auto cartridge was in progress, in September of 1904 two M1902 Colt .38 automatic pistols were shipped to John M. Browning to convert to .45 and try to work out some of the problems that had been encountered in earlier testing. His first challenge was to find a way to prevent the barrel links and pins from being warped and broken by the pounding from the heavy cartridge. He tried a number of approaches, but quickly settled on a simple and direct method of removing the stress on the small parts. He already had three locking lugs on the top of the barrel to lock the action when the pistol was fired. He simply extended the lugs downward to lock the barrel to the frame during slide recoil. The bottom portion of the lugs was triangular, each lug fitting into a matching triangular cut in the top of the frame. When the barrel moved back and down during recoil, the three lugs mated with the frame cuts, allowing the frame to absorb the energy of the exiting bullet.

A patent was applied for on 25 May 1905 and granted on 19 December of the same year, covering several potential barrel designs. The only portion of the patent that was actually applied to the production gun was the triangular lug barrel locking arrangement. The rest of the gun was pretty much just a strengthened and slightly enlarged Model 1902 Military, with a shortened barrel and slide and an external extractor. There was still no safety other than a half-cock position for the hammer.

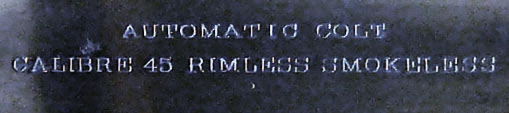

On 8 June 1905 a prototype was shipped to Frankford Arsenal to allow them to test the new .45 cartridges. In September 1905 the Ordnance Department purchased another pistol for further testing --either a prototype or a very early production pistol. Commercial manufacture began in late September or early October, and the first production M1905 was shipped on 1 December 1905. Like its .38 predecessors--the M1900 and M1902--the M1905 was hand machined and hand fitted, so the weight varied slightly from gun to gun. The guns were given an oil polish mirror finish and heat blued in a coal-fired oven. Small parts were finished in a brilliant fire blue. John Potocki says: “This process produced what many believe is the most beautiful finish ever put on a firearm. Unfortunately, the finish is quite delicate and, as such, high condition specimens are prized items today.” The right side of the slide was marked: AUTOMATIC COLT

There were five different left side slide markings. Approximately the first fifty pistols bore the following inscription: “BROWNING’S PATENT” COLT’S PATENT FIRE ARMS MFG. CO. However, serial number 32 (and possibly others) bore the following inscription: “BROWNING’S PATENT” COLT’S PATENT FIRE ARMS MFG. CO. As of January 22, 1906, Browning relieved Colt’s of its obligation to add his name to each pistol. Sometime soon after serial number 50, and continuing through approximately serial number 4000, Model 1905s bore the following inscription:

PATENTED COLT’S PATENT FIRE ARMS MFG. CO.

In the final years of production, Colt’s name and address were abbreviated as follows:

PATENTED COLT’S PT. F.A. MFG. CO.

Most pistols up to serial number 3600 had rounded stub hammers with hand-cut checking on their upper surface (though spur hammers were sometimes special ordered). Hand-cut checking can be identified by the border line around it, and there are minor variations between individual specimens. After serial number 3600 most specimens have spur hammers with a thick spur and hand-cut checking. A few rare pieces (in the 3800-400 serial number range) have a thin spur hammer similar to the one on the Model 1907. Late pistols have the thick spur hammer with machine checking, which can be recognized by its lack of a border and its fine straight lines.

Grips were hand-checked walnut with diamonds around the ferrules. Approximately 440 Model 1905 pistols were cut to take a combination holster/shoulder stock, of which approximately 408 were actually shipped with the holster/stock. On 31 January 1906 the Chief of Ordnance, General William Crozier, sent a letter of invitation to a number of inventors and manufacturers inviting them to submit pistols to be tested for use by the Army. Automatic pistols were required to use the “Cal. .45 U.S.A. Experimental Cartridge” provided by the Frankford Arsenal, which had been designed by Colt’s in conjunction with U.M.C. (though some sources say Winchester). Eighteen companies and individuals responded, but only eight actually supplied arms. The tests were scheduled to begin on 12 September 1906, but due to delays in communication with overseas manufacturers, as well as difficulties in the manufacture of ammunition at Frankford Arsenal, the tests actually began on 15 January 1907. Colt’s provided two of its Model 1905 pistols. However, they were not production pistols. They lacked serial numbers, had thicker grip pieces, a modified magazine, and rectangular lanyard rings staked to the bottom of the grip frame on the left side. The guns were marked only with COLT’S PATENT FIRE ARMS MFG. CO. on the left side of the slide. One gun had a rounded hammer, and one gun had a spur hammer. The Colt pistols were tested with both commercial and Frankford Arsenal ammunition. According to Bady, the Colt pistols “had fewer malfunctions, misfires or jams with the commercial ammunition than did any other automatic pistol or revolver at the trial. With Frankford Arsenal ammunition, the Colt had more jams than any of the other weapons that reached the final stage of the trial.” I speculate that Colt’s had tested their guns primarily with ammunition supplied by either U.M.C. or Winchester. Ultimately, the Ordnance Board recommended that the Colt, Luger, and Savage pistols be tested further, but they specified that the Colt & Savage should be modified to eject upward rather than toward the side, provide a loaded chamber indicator, an automatic safety, a spur hammer, and a magazine release that could be operated one-handed. They also recommended that the pistols be tested in the field by at least three cavalry troops. DWM declined the order for the Lugers. A “Circular Advertisement” was issued on 6 May 1907 soliciting bids for the provision of 200 Colt and Savage automatic pistols with “top ejection, automatic indicator to show that the chamber is loaded, satisfactory automatic safety, and wooden grip plates securely fastened on...,” spare parts also to be provided, and for 100,000 rounds of .45 ammunition with 230 grain bullets, loaded to provide a muzzle velocity of at least 800 feet per second. I don’t know why the request for a one-hand magazine release was dropped, but it may have been Colt’s influence, since they didn’t have one on their pistol.. The advertisement also specified that the Colt pistols must have a “strengthened trigger stirrup, and lengthened trigger stirrup pin.” Colt’s responded almost immediately that they could provide the requested pistols within four months of the placement of an order, at a cost of $25 each. Savage did not have the equipment or the money to fill the order at the time. Ultimately, however, Savage agreed to provide 200 pistols at a cost of $65 each, and signed a contract in October of 1907. The additional cost for the Savage pistols would allow Savage to tool up for mass production. The Colt Model 1907 Automatic Pistol

Colt’s asked three of their employees to work on a loaded chamber indicator and a safety. These employees were George Tansley, Carl Ehbets, and James Peard. Peard designed a simple loaded chamber indicator that raised the corner of a rectangular piece of metal above the level of the slide when the chamber had a round in it (patent #891,438). The loaded chamber indicator was placed on the left side of the top of the slide, behind the ejection port. Tansley and Ehbets each designed safety mechanisms, and features from both mechanisms were eventually combined into a grip safety for the new pistol that blocks the sear and withdraws the firing pin into the slide (Tansley’s patent #891,510, and Ehbet’s patent #917,723). The ejection port on the Model 1907 was extended into the top of the slide to allow for vertical ejection, and the ejector was repositioned and extended forward to help throw the empty shells upward. The left grip was truncated to allow room for a U-shaped lanyard to be staked to the frame. A prototype of the Model 1907 pistol was ready by September of 1907 and was submitted for approval by the Ordnance Department; manufacture probably commenced in late October or early November. The entire order of 200 pistols was shipped on 17 March 1908, and the pistols were issued to men in the 2nd, 4th, and 10th Cavalry probably in late September or early October. The Model 1907 was reported to be accurate, but not much else good was said about it. The problems encountered were numerous. The sears had not been adequately heat treated, so they broke regularly. Pressing hard on the grip safety would sometimes cause the gun to fire. Firing pins broke, as did loaded chamber indicators, and the pistols failed to feed or eject often. Meadows provides detailed information about the various tests that were performed and reports that were filed. The Ordnance Department requested Colt’s to make improved sears. Colt’s manufactured the sears before the end of 1908 and they were probably installed in the pistols by troop armorers before the end of March 1909. But as negative reports continued to filter in, Colt’s requested that the pistols be returned to them for further modification. The guns were sent to Colt’s in lots of 10 or 15 from July through December of 1909. Colt’s increased the size of the ejection port slightly, installed a hammer with a thinner spur that was angled slightly differently, and added a spur to the grip safety so that when the hammer was pulled all the way to the rear it engaged this spur, deactivating the safety and allowing the hammer to be lowered. The modified guns were better, but still not perfect. However, by the time the final reports were made in 1910, Colt’s and John Browning, having learned what lessons they could from the government trials, had already moved on and created the Model 1909 and the Model 1910 (neither of which was ever commercially produced) on their way to perfecting the Model 1911, which was eventually accepted as the U.S. service pistol. The Ordnance Department ordered an additional five Model 1907 pistols in January of 1908 to give away as marksmanship prizes, and a couple more later, purpose unknown. According to Potocki, a total of only 207 Model 1907 pistols were ever made. They are some of the most desired collector guns in the world. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright 2009 by Ed Buffaloe. All rights reserved. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||