|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Making P.O.P.

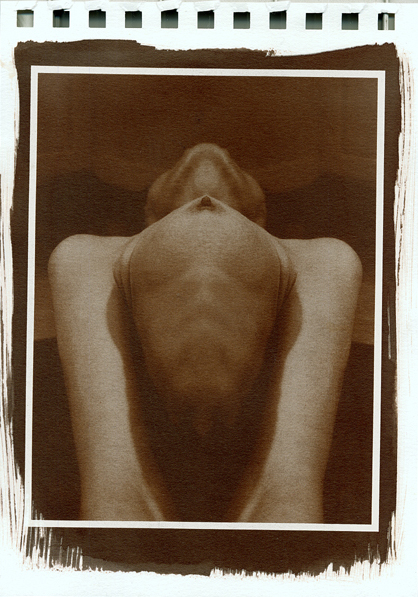

POP is a contact process that usually gives a long scale and a yellowish-brown image after fixing, though various hues of brown are possible with different formulae, and toning permits further control (in the purple-black range). With the contrast adjusted, POP can handle just about any kind of negative. It is some years since I made silver-gelatin emulsions, and my present excursion began with several (mostly very old) published recipes. None gave quite what I was hoping to find, so I decided to build my own from scratch, which would also give me the opportunity to explore some of the variables involved. As it happened, the journey was not a particularly long one; I have done some experiments with lead, cadmium and other exotic additives, but so far have obtained the best results from the very simplest formulations. I don’t pretend that this short article is definitive, or even a particularly thorough exploration of the many variables in print-out emulsion making; rather, it gives reasons for the formulae that I finally arrived at, which, I feel, are as good as anything else I’ve seen, and better than some. There are many ways in which they could have been different (notably in my choice of salts), and, no doubt, could be better still. (The “contrasty” version of the emulsion described here is much slower than Centennial POP, but in other ways quite similar.) Various authorities tell us that liquid POP emulsions do not keep, yet published recipes, sometimes for large volumes of emulsion, may neglect to mention that coating should immediately follow ripening, a fact I am sure has caused much disappointment and waste of materials. I have proved to myself that liquid POP emulsion can have a reasonable shelf life (refrigerated), but have come to prefer a two-part formula (i.e. separate salt-gelatin and silver solutions) to be mixed for immediate use. The chief advantage of this is better consistency between prints as there is no danger of ripening (increase of speed, accompanied by increased fog and loss of contrast) in storage or with remelting, but several salt-gelatin solutions, each working with the same silver solution, may be made to cope with each type of neg to be printed (Pt/Pd, cyanotype, straight silver-gelatin, etc.) It is possible that certain additives may need some time in the mixed emulsion to interact and have their full effect, but everything I have tried so far seems to work fine straight after mixing and so I see no need to bother with a ripening stage. Quick Overview Photographic emulsions have a high gelatin content and are solid at normal ambient temperatures, so must be heated to 40°C or more to liquefy for coating. This is most easily done by standing the emulsion container in a vessel of water at 50-60°C for a few minutes. Coating is in the usual way – brush, glass rod, etc., and may be done under incandescent light since POP is virtually insensitive to visible light. Drying is probably best in darkness since it must be thorough and takes several hours (5-6 hours recommended). Gelatin solutions set to form a jelly at first, but should be dried, without heat, to the hard, horny layer that forms when they lose all their moisture; printing with an emulsion that is just touch-dry poses severe danger to the negative with which it is in contact - the interior of the emulsion layer also needs to be dry. A full, purple-red print-out is obtained, but printing needs to be deeper than required because of the density loss that occurs in processing, though there is some recovery on drying. Processing consists of an initial wash, fixing and a final wash. Usually, prints are toned with gold, before or after the fixing step; either way intensifies the image. Toning produces its own colour changes, but without prior toning, a (usually undesirable) shift to yellow-brown occurs in the fix. There is some movement back towards red with dry-down, but dry prints always look very different to when they left the printing frame. “Self-toning” paper can be made by incorporating a gold salt in the emulsion, which comes into play in the fixing bath. The toning colour can be varied with the strength and temperature of the fixer: the stronger the fixing action, the greater the loss of density and cooler the colour (but see note under Self-toning Papers). The Gelatin The gelatin content of an emulsion determines the coating thickness and therefore the amount of silver salts per unit area, and in some cases makes an important contribution to D-max, but emulsions which have a high silver content may be less affected. Published POP formulae typically contain 80-100 g of gelatin per litre, but I found this too much for hand coating methods; while it appeared to go down OK, prints usually came out streaky. The less the gelatin, the easier it coated (but note that all my tests were on a “difficult” hot-pressed paper, and that a low gelatin concentration may be less suitable for more absorbent

papers). The image also seemed to become cleaner and sharper, though there was a small loss of printing speed. Other advantages of low gelatin are faster drying after coating, printing qualities more constant with

variable humidity, better (redder) image colour and little gloss. Finally, I arrived at 46 g/L (grams per litre) of gelatin. A watery emulsion soaks too far into some papers (particularly since it must be applied warm), and the gelatin starts to break down after remelting only four or five times, making the emulsion more acidic and changing its photographic qualities. These changes are not necessarily for the worse (at least, not until it has been remelted a few more times), but I felt that it needed to be stable through at least 15-20 remeltings. Heat alters the chemical and physical properties of gelatin, which is one reason why only small quantities of emulsion should be made up at a time, or, if larger quantities are made, it should be kept in small containers. Damage takes longer and is less severe with stronger solutions; my gelatin would therefore be kept in a stronger solution, to be diluted to 46 g/L (4.6%) for use. Gelatin has a large influence on the image colour; depending on the chemistry, normally in the yellow-brown region after fixing. This is the case even when very little gelatin is used, and using different

salts of silver in the emulsion, or certain additives, has much less effect on the colour than it would in, say, a salt print (without gelatin sizing, of course!) One caution: mould growth can be prevented by thymol or other antiseptics, but another big enemy of gelatin solutions is extremes of temperature. Gelatin must never be boiled when preparing or re-melting the solution. It should also be kept refrigerated when

Albumen In the course of my testing, I did try adding small amounts of egg albumen (as a solution of powdered egg white) to gelatin emulsions and found that it has a beneficial influence on the coating properties and image colour, and imparts a subtle, not unattractive gloss. But what I read about the permanence of albumen prints suggests it is not a good idea if long term stability is an issue. For details, see for example Reilly’s The Albumen and Salted Paper Book, or Ware’s Mechanisms of Image Deterioration in Early Photographs. The Salt Many salts of silver darken under UV and have uses in silver and iron-silver printing-out systems; silver nitrate on its own is not light-sensitive, but forms sensitive compounds when mixed with suitable salts (citrates, tartrates, phosphates, chlorides, iodides, etc.) In salt printing, silver chloride gives the greatest density and is invariably the main one used, usually together with an organic silver salt such as the citrate or tartrate. Perhaps I was wrong to assume that what is true of salt printing would also hold for POP, but it gave me somewhere to start and I would see what happened… A POP emulsion contains, as an absolute minimum, gelatin (or collodion) and a sensitive silver salt – made in situ by combining salt and silver nitrate - together with some “extra” silver nitrate. My tests therefore began with just silver nitrate and sodium chloride (for which I used ordinary table salt; the additives it contains do not appear to influence its photographic properties to a noticeable degree). As we shall see, the amount of silver nitrate required in an emulsion is largely determined by the amount of salt it contains (or vice versa if you chose to look at it the other way round!), and I knew from salt printing that, within reason, more chemistry on the paper (salts and silver nitrate) equals a stronger, brighter image. However, more salt requires more silver and there is a point beyond which no further advantage is gained. After testing, I decided on a salt content of 9 g/L. Contrary to expectations, sodium and ammonium chloride produced identical results in chemically equivalent amounts; I chose sodium as it is cheaper and more easily available (as table salt). It gave a reddish-brown image colour with reasonable D-max, but rather poor shadow separation and slightly foggy highlights (due to what old texts call spontaneous darkening, that is, without exposure), and a very soft print that would require a negative range around 3.0. Tri-sodium citrate was also tried (Na3C6H5O7.2H2O), producing a colder brown colour with somewhat lower D-max and greatly increased contrast (necessary neg range about 1.5). The fog was also eliminated! With gelatin and a little citric acid (discussed later), tri-sodium citrate and silver nitrate alone make a perfectly good POP emulsion for contacting ordinary camera negs (bromide printing quality) - giving a colour that is too cold for my taste, but I might consider it for some subjects. Mixtures of chloride and citrate gave the best results, with lower fog, higher contrast and improved tone separation compared with straight chloride emulsion, but the citrate had little effect on image colour, chloride being the dominant influence. Adding citrate to a chloride emulsion also increases D-max a little; it rises with the proportion of citrate, but goes down again after a certain point (though contrast continues to increase). A 25:75 (chloride:citrate) mix gave good D-max and shadow separation, and printed 12 steps of the Stouffer, which is roughly the range of a camera negative with the correct contrast for bromide printing. With 9 g/L of salts and a 25/75 mix of chloride and citrate, therefore, my emulsion would use 2.25 g of sodium chloride and 6.75 g tri-sodium citrate per litre. (Tri-sod. citrate is also known as tri-sodium salt of citric acid, or plain sodium citrate.) The Silver

Sufficient exposure to light (or ultraviolet radiation in this case) liberates the halogen (chlorine, bromine or iodine) from a silver halide crystal to leave just a grain of silver behind, but emulsions without an excess of silver nitrate show little darkening. An explanation that has been put forward for the print-out effect with excess silver (Hermann Vogel, cited by Reilly) is that with an excess of silver, the escaping chlorine (for example) reunites with free silver nitrate to form fresh silver chloride, which in turn forms another grain of silver. With a large excess of silver (and continued exposure!), this “recycling” may take place many times. To my mind, this explanation can’t be quite complete. If we have a 100% excess of silver nitrate (twice that needed to combine with all the salt), then the amount of extra silver halide that can be formed in an area receiving full exposure is no more than was there at the beginning (i.e. the maximum is double that of the same emulsion with no excess), yet the difference in D-max between zero and 100% excess emulsions can be enormous. Nevertheless, it remains a fact that a surplus of silver is necessary in printing-out emulsions. The POP formulae scattered throughout the literature do not give much of a clue how large an excess of silver over salt is required, insofar as there is little agreement between them. From this I concluded that the optimal size of the excess would vary according to the salts in the emulsion (as well, no doubt, as other factors), and would have to be found by experiment. I knew from past experience that a small excess of silver gives only a pale image that is not very satisfactory. Overall density and D-max increase with the excess, but only up to a certain point beyond which further addition of silver is simply wasteful. Looking at a selection of old recipes, I calculated that the size of the silver excess varied roughly between 50% and 100% (i.e. up to twice as much silver nitrate as necessary to deal with all of the salts they contained). I would start with a small excess, and see the effect of increasing it. Now, I had already decided on the salts in my emulsion (see above), so it was first necessary to know how much silver nitrate would be needed to change them into their corresponding silver salts. Starting with sodium chloride, the reaction that occurs when it is mixed with silver nitrate is: AgNO3 + NaCl → AgCl + NaNO3 [Silver nitrate + sodium chloride forms silver chloride + sodium nitrate] The silver chloride, being insoluble, is precipitated, while the soluble sodium nitrate stays in solution. The relative atomic masses (formerly called atomic weights) of the elements involved will be found in any chemistry text and are as follows:

From these, the relative molecular masses of the compounds can be worked out: Silver nitrate (AgNO3) = 107.868 + 14.007 + (3 X 15.999) = 169.972 This tells us the proportions in which the different chemicals combine: 169.972 parts of silver nitrate and 58.443 parts of sodium chloride become 143.321 parts of silver chloride and 84.994 parts of sodium nitrate (all of the silver nitrate and sodium chloride being used up; that is, without any silver or salt left over). This is true whether a “part” is a gram, a pound or a ton, as long as we stick to the same units throughout. The amount of silver nitrate required to completely convert 2.25 g of sodium chloride to silver chloride is 2.25 multiplied by 169.972 (the relative molecular mass of silver nitrate) and divided by 58.443 (the relative molecular mass of sodium chloride). This comes out at 6.54 (2 d.p.); every 1g of sodium chloride in my formula therefore requires 6.54/2.25, or 2.91 g of silver nitrate for complete conversion. Or, to put it another way, the sod. chloride:silver nitrate ratio is 1:2.91. For tri-sodium citrate, the reaction with silver nitrate is: 3AgNO3 + Na3C6H5O7.2H2O → Ag3C6H5O7.H2O + 3NaNO3 + H2O [Silver nitrate + tri-sodium citrate forms silver citrate + sodium nitrate + water] The relative molecular mass of 3AgNo3 (3 molecules of silver nitrate) is 509.64; of tri-sodium citrate, 294.1; of silver citrate, 530.661; of 3 molecules sodium nitrate, 254.97; and of water, 18.015. Every 294.1 parts of tri-sodium citrate thus requires 509.64 parts silver nitrate, which simplifies to 1:1.73 (tri-sod. citrate:silver nitrate). Or, for the 6.75 g tri-sod. citrate in my emulsion, 11.68 g of silver nitrate. The total of silver nitrate required is therefore 6.54 g + 11.68 g, or 18.22 g. I took a 33% excess of silver nitrate as my starting point, which means 24.23 g (18.22 multiplied by 1.33). This was increased, a little at a time, until the point was reached where further additions of silver made no difference to the resulting image. This point (representing the best D-max and tone separation) was with a 100% excess of silver, which means a total of 36.44 g silver nitrate. With reference to the very variable silver excesses that appear in published formulae, it is interesting to note that in all my experiments with different combinations and proportions of salts, I consistently found a 100% excess to be best. With less than this amount, D-max is lower and tone separation poorer, while there are no benefits to be had from using more. Halogen Absorbents and Preservative Reduction of silver chloride to silver by light can only occur in the presence of something that will absorb the liberated chlorine, and this is mainly performed by water vapour, present in even the driest atmosphere. The sensitivity of POP is therefore somewhat variable, and greatest with high humidity, which also means that incomplete drying is likely to give rise to patchy results. Moisture is thus an accelerator and since the emulsion itself contains water, silver reduction can take place even when refrigereated. Cold-stored, it happens only slowly, but with constant remelting the emulsion has a very short life. It may be prolonged quite considerably if something with an affinity for moisture – and without any harmful effects – is included in the formula, to hamper the absorption of chlorine. Such a substance is citric acid, and it improves the keeping qualities of coated paper by slowing down “spontaneous darkening”. In published formulae, the amount of citric acid is usually about equal to the weight of silver nitrate, but quantities of that order have what I consider adverse effects on the image, cooling the colour, and reducing D-max and shadow separation; smaller amounts appear to preserve just as well, and I decided on 11 g/L. Free silver nitrate in the emulsion is also a halogen absorbent (see Vogel’s explanation, earlier), and organic salts of silver possibly are too. They are sensitive to light, but less so than silver chloride and (in a chloride emulsion) appear to take up the chlorine liberated by exposure of silver chloride to form fresh silver chloride, in much the same way as free silver nitrate (but not as a very effective substitute for free silver nitrate). [That organic silver salts are halogen absorbents is not, as far as I know, beyond dispute, but my results suggest it to be true since silver citrate has very much less influence on the image colour than I feel it otherwise ought to have.] Accelerators When light acts on silver chloride in the presence of moisture, hydrochloric acid gas is formed as the silver chloride is reduced to silver, and oxygen is liberated as a by-product. If the emulsion contains something to absorb this oxygen, printing is accelerated. Nitrites and sulphites absorb oxygen to become nitrates and sulphates, but the nitrite or sulphite itself is not a halogen absorbent; it merely facilitates the take-up of the halogen by moisture. Small amounts of sodium sulphite may increase the sensitivity of an emulsion quite considerably, but the loss of contrast can also be dramatic. Printing is fairly slow without it (taking about twice as long as cyanotype), but I do not see this as a serious problem, or the extra speed worth taking on a new problem with contrast. I therefore see no good reason for using accelerators. Antiseptic To protect the gelatin (and the tri-sodium citrate, which also attracts mould), 10 ml/L of a 2% solution of thymol in ethyl alcohol is added per litre of emulsion. (Other alcohols should be fine, including denatured methylated spirit.) Thymol is the antiseptic that I’m most familiar with, and I’ve had no trouble at all with DOP (develop-out) emulsions containing 10 ml/L. One suggestion for an alternative would be 3 g of salicylic acid per litre. Hardening Gelatin solutions containing a useful amount of hardener cannot be re-melted easily, so it is best to add it only to small amounts of emulsion immediately before use. Previous experience had shown that a properly made emulsion does not need hardening when used on paper (as long as handled carefully while wet), but I definitely recommend it in the first coat when double-coating (since heat and moisture from the second coat will otherwise disturb the already dry first coat), or if working on non-absorbent surfaces. 5 ml of glyoxal is suggested per litre of emulsion, though other hardeners are also suitable. For small amounts of emulsion, this is equivalent to 1 drop per 10 ml emulsion, assuming 20 drops to 1 ml. For smaller amounts still, make an 8% solution by diluting 1 part glyoxal with 4 parts water (standard glyoxal is a 40% solution), and add 1 drop to every 2 ml of working emulsion. Contrast Control

Sulphites and nitrites reduce contrast, as discussed, while several chemicals will increase it (e.g. dichromates, chlorates, chloramine-T), which presents two possibilities: start with a hard emulsion and use additives to make it softer when necessary, or use an inherently soft emulsion with additives to make it harder. But, preferring to keep life simple, I chose a third way. Since the emulsion is mixed before use from separate gelatin-salt and silver solutions, we can make two - or more! - different gelatin-salt solutions (the ingredients of which are very cheap), and select the one most appropriate to the job in hand. I propose just one extra gelatin-salt solution, to handle negs with a range around 1.8. It was mentioned earlier that the proportion of tri-sodium citrate altered the contrast of the emulsion, and this means alone affords enough control for our present purpose. Using a 25:75 ratio of chloride to citrate (as described under The Salt) produces fairly high contrast, but with a 75:25 chloride to citrate ratio the emulsion gives the longer scale that is needed for our “alternative” negs. The normal (contrasty) emulsion is made with 2.25 g sodium chloride and 6.75 g tri-sodium citrate per litre, so the new gelatin solution will need 6.75 g sodium chloride and 2.25 g tri -sodium citrate. The colour is the same with the softer version, but it prints a little quicker. But remember that sod. chloride and tri-sod. citrate combine with different amounts of silver, so the amount of silver nitrate solution needed in a given volume of emulsion will differ according to which gelatin-salt solution is used. This is covered under Mixing and Using the Emulsion. Preparation Starting with the contrasty emulsion, the ingredients of the formula I had decided on were as follows (for 1 litre):

These would be contained in two solutions – the silver nitrate in one and everything else in the other. The gelatin-bearing solution would also be made stronger, to be diluted for use, in order to give some protection against the effects of heat. One way to do this would be to make a small volume of strong gelatin-salt and a large volume of weak silver solution (rather than preparing equal volumes), but I had found that the emulsion is better when a strong silver solution is used. Both would therefore be made fairly strong, and some distilled water added at the time of mixing the working emulsion. The mixture would be two parts of gelatin-salt, two parts of distilled water, plus one part of silver nitrate solution, in that order. Since a little emulsion goes a long way, 1 litre is a very large amount and so the batch size would be 500 ml; the above quantities are therefore halved and the two parts are:

(In many formulae, the citric acid is included in the silver solution, but a different emulsion results. I preferred it in with the gelatin and salts. Early tests had, in fact, shown that it is best to add dry citric acid separately, after the two solutions have been combined, but I wished to avoid this complication. Note also that it is NOT essential to work to an accuracy of 3 decimal places!) The silver solution is quite straightforward: simply add the silver nitrate to about 80 ml of distilled water, top up to 100 ml when it has all dissolved, and store in the dark. For the gelatin-salt solution, the salts and citric are dissolved in about 150 ml of distilled water (room temperature) in a wide-mouthed beaker, then the gelatin is sprinkled evenly over the surface and left to stand for about 15 minutes. This is important – simply spooning in the gelatin causes the granules to stick together in a lump that makes solution very difficult. Sprinkling and soaking, the granules sink to the bottom and swell (and in about 10 minutes absorb nearly all of the water), but they stay separate. The beaker is then placed in a larger container of moderately hot water for perhaps 20 minutes, until a perfectly clear, homogenous solution free from strings and bubbles is obtained. At this point, add distilled to make up to 200 ml, then the thymol, and bottle. Separately, the solutions are insensitive to light (as long as the silver solution remains uncontaminated), and the work may be done in any kind of light. After soaking the gelatin, the temperature needs to be raised above 40°C, the approx. melting point of gelatin, but not too high because of the danger of heat damage. In my tests the water bath was held at an estimated 60°C , with control by dipping my finger and adding hot water from the kettle when necessary.

Mixing and Using the Emulsion Only small amounts of emulsion tend to be needed – 5 ml, for example, is more than enough to cover an A4-sized area of hot-pressed paper. For this, 2 ml of gelatin-salt, 2 ml distilled water and 1 ml of silver solution would be needed, but it is probably a good idea to mix a little more – say, 10 ml – until you have had some practice coating, or for more absorbent papers. The solutions must, of course, be warmed in a water bath before combining (to about 50°C), and measurement is most conveniently by syringe. To keep the emulsion fluid until coated, I measure onto a saucer standing on a warm dish heater, first the gelatin-salt, then the water, and finally the silver, which causes the mixture to turn white after a few seconds. Note that the order of mixing makes a difference, and use a small paintbrush or similar implement to ensure that it is thorough. Any required “finals” are added and mixed in at this stage, e.g. a drop of concentrated wetting agent, hardener, glycerin, alcohol, etc., after which it is coated by the chosen method. I have so far been using foam brushes on prints up to A4 without any difficulty; the emulsion coats much more easily, and does not start to set so quickly, as emulsions containing more gelatin. Apart from hardener when needed, or a little glycerin to prevent bubbles if using Knox gelatin, I do not recommend any other additions. (The amount of glycerin should be small – e.g. 0.5 ml per 10 ml emulsion – as it makes the emulsion extremely fragile during processing.) Dry in darkness, and allow 5-6 hours. Areas of higher density in the print usually indicate insufficient, uneven drying (the effect of residual moisture on printing speed), whereas the free silver nitrate may stain the back of prints by bleeding through if left too long between coating and printing (drying times up to 12 hours are usually safe). Under an upturned print dish – preferably red – is fine if you do not have a suitable space to leave coated papers, though drying will take longer without free access of air. A single coat normally gives excellent results, but they’re even better with double-coating (much higher D-max, improved tone separation). It is important to add hardener to the first coat (see Hardening), and to let it dry well before applying the second. Hardener in the second coat (or a single coat) serves no very useful purpose when working on paper, but can be included if desired . (Hardening offers some protection against softening or melting of the gelatin by over-warm processing solutions, but high temperatures should be avoided; try not to work above 20°C). The same 2:2:1 proportion used for mixing the No. 1 emulsion do not suffice for the No. 2 emulsion; it is reasonably close, but a little more silver is needed for the best results. As explained earlier, 2.91 parts of silver nitrate are required for each part of sodium chloride, and 1.73 parts for each of tri-sodium citrate (without excess). For the 1.125 g tri-sod. citrate and 3 .375 g sod. chloride in the No. 2 gelatin-salt solution, 11.77 g (rounded) of silver nitrate is needed, which becomes 23.54 g for a 100% silver excess. If using the No. 2 gelatin-salt solution, therefore, the proportions are 2 parts gelatin-salt, 2 parts distilled water, and 1.3 parts of the normal strength (18.22%) silver nitrate solution. Many factors – such as temperature, which solution is added to which and how quickly, etc. – can make a difference to the characteristics of the emulsion thus obtained, but I paid no more attention to them than I felt was absolutely necessary; my aim was simplicity rather than absolute consistency from one mix to another. Differences certainly exist, but tend to be very minor and can, if deemed necessary, be minimised by closer attention to the details of preparation; differences in measuring accuracy, the coating thickness, drying times and humidity can give rise to greater variability between prints. It is also true that “careless” preparation of the emulsion does not produce nearly as much variation as in develop-out emulsions. Drying/Keeping Time Coated papers must be fully dried before printing, by which I mean that their humidity should reach equilibrium with the air around them. Do not, therefore, use heat as making them too dry

will have an adverse effect on the image characteristics, even if it doesn't melt the emulsion. Negative & Exposure Assuming that the contrast of the negative is right, the important thing for a good print is that the shadows should be clear. While the emulsion can be altered to handle negs with different ranges, a neg with low b+f density gives a better print than one with high b+f (and the same density range). The ideal is that the deep shadows should just reach D-max in the time it takes to print the highlights to the correct value. Everything I have read about POP says that heavy overprinting is needed because of the large density loss in the fix. There is a loss, certainly, but not nearly as much as I felt I’d been led to expect, and most of it is recovered with dry-down (though the original D-max remains diminished). With a step wedge, there is a loss of three or four steps in the fix, but after drying only one or two steps have been lost, though they are all somewhat lighter. However, delicate highlight detail has an unfortunate habit of disappearing in the fix. If using a split-back frame or other means to allow inspection during printing, expose for the highlights - note the time taken to produce good highlight detail, and continue printing for as long again. First Wash

The image becomes lighter in the first wash, but retains its colour. In the fix, it fades rather more (3-4 steps), but, as already stated, dry-down restores much of the lost density. At first, the colour turns a cold brown in the fix, but after a couple of minutes it enriches to an orange-brown.

Fixing The density loss and colour change on fixing (without prior toning) cannot, unfortunately, be avoided - or significantly reduced - by using very weak hypo solutions, so to assure maximum permanence a fairly strong fixer should be used. Making it slightly alkaline has some effect in minimising changes, and has other benefits in that alkaline hypo washes out of prints quicker and more completely, and is less likely to precipitate sulphur; the inclusion of sulphite also offers protection against sulphur formation. Alkaline hypo also yields a stronger image because the higher pH gives a gentler fix with less bleaching action.

Fixing time is 10 minutes. (To me, this sounds unnecessarily long if prints are first well washed to rid them of free silver nitrate, but 10 minutes is what all the books say for old commercial POP papers.) The condition of the fixer influences the image colour, as dissolved silver salts accumulate in the fix. With the emulsions given, and fresh fix as above, the colour after drying is a rich chestnut -brown, but this gradually turns to a colder purple-brown as the fixer ages, which affords another measure of control. However, the Ilford Manual of Photography, circa 1935, states that fresh fix should be used for each batch of prints (though it does talk about batches of 20 or more!) A colour shift will be noticed quite soon (after perhaps only 5 or 6 8X10s with a litre of fix), and if the purple-brown prints resulting from a used fix are then put into freshly made fix, they retain their colour and do not undergo any other changes. This, I am sure, indicates that they are fully fixed by the first solution, and that reusing fixer is perfectly safe within reason. The capacity of the fixer cannot be stated with accuracy since it will depend on image densities, emulsion coating thickness and paper absorbency as well as how much, if any, residual silver nitrate carries into the fix, but what can be said is that the much smaller silver grains of POP are much more susceptible to attack than DOP papers and that thorough fixing is therefore even more important. I would not treat more than 20 8X10s per litre, and use two-bath fixing for important work. Combined toning and fixing baths were for a long time popular for POP (long after their use on albumen papers had been discredited!), but they are not to be recommended. Under the right circumstances, combined baths can, apparently, match the permanence conferred by separate toning and fixing, but several factors can cause the formation of sulphur in the solution, which then becomes extremely harmful to prints. The final wash should be 45-120 minutes, depending on paper thickness. The emulsion should withstand such times (and longer), but may become unduly soft if the wash water is too warm. If the water from the cold tap rises much above 20°C in summertime, it would be a good idea to include some hardener in the emulsion. Take care to prevent abrasion of prints swirling in the wash. Toning Toning is traditionally with gold and/or platinum, though other toners are also said to work. Usually, too, toning is done before fixing to minimise density loss in the fix, but allowance can be made for this and I prefer the results from post-fixation toning. Toning Before the Fix Toning before the fix is done with gold. Any formula may be used, diluted if necessary for control. The instructions with Centennial POP paper give formulae for thiocyanate- and alkaline -gold toners, both of which do much the same thing. Both are also very weak (as for salt prints), but I prefer the slightly stronger thiocyanate-gold recipe from the Ilford Manual of Photography:

The gold solution should be added in small doses to the well stirred mixture of water and sulphocyanide solution. On each addition a red colour is produced and disappears on stirring. The Ilford Manual’s instructions for toning POP are as follows: Prints are placed one by one face down in the toning bath, preferably at 65°F., and kept always moving by withdrawing the bottom print by one corner and bringing it to the top. Within 5 or 10 minutes prints lose their red colour and assume their characteristic purplish tone, first in the light parts and next in the heaviest shadows. In judging when to stop toning, the print is held up to the light; when examined in this way it should show a slight reddish tinge in the deepest shadows, and is then transferred to a dish of clean water. In making a number of P.O.P. prints from one negative or from a variety of negatives of uniform quality, it is important to obtain the same tone throughout the batch. The best way to do this is to mix enough of the toning bath for, say, 20 prints, immerse all the prints in it as quickly as possible and take out all together. About 40 prints of quarter -plate size are toned by 20 ozs. of the above bath [equals approx. 12 8X10s per litre], and so any reasonable number may be toned on this system by allowing half an ounce of toning bath per print. The bath is then thrown away and fresh measured out for the next lot of prints. Depending on the toning time (up to about 10 minutes), the result is a colder, darker print that tends towards purple. Permanence is increased in proportion to the degree of toning, but toning must be followed by a 15-minute wash before fixing (with fixing for the full 10 minutes, in the formula given earlier). Even a short tone (e.g. 2 minutes) has a significant effect in increasing density and cooling the colour. Toning After Fixing

Selenium works fairly well in sufficiently weak solution (too strong causes image bleaching), though in my opinion the colours are inferior to gold. It needs to be used at about one-tenth of normal working strength (which, for Kodak Rapid, means a dilution around 1+39), and gives purplish colours. Prints must be well washed after fixing, and are immersed in the selenium for anything up to 10 minutes (by which time its action will have gone to completion). They will appear to fade if put in dry, but they do this in water too, and it is simply the “undoing” of the dry-down effect. The initial orange-brown colour starts to look pink-brown after about 2 minutes, after which the colour becomes gradually more neutral. After the full 10 minutes, prints still retain a hint of redness, but this disappears (and the tones darken) on drying. Toning with gold after the fix, tone separation is better than before fixing, and stronger purple to black tones are possible. I prefer the deep blacks obtained with a stronger toner than that used for pre-fix toning. With the thiourea-gold formula that I gave in Post-Factory #3 (repeated below) dry prints fade on entering the toner (see above), and start to strengthen after about 30 seconds . After a minute, the image is like its former self (i.e. an orange-brown tone), slightly intensified. After 2 minutes it has become reddish brown in tone, and after 3 minutes it is a still colder purple brown with greatly increased D-max. Further change is slower, but what we finally end up with, after about 5 minutes, is very intense, neutral black shadows that give way to a pinky-brown colour in the midtones. Before toning with gold, prints must be well washed of any residual hypo, which could cause stains and/or impair permanence. Prints may be removed to the wash at any stage of toning. Very short toning times probably do not do much to enhance permanence, but toning continues for a while in the wash. After washing for 15 minutes, another short fix is required before the full , final wash. This is because toning changes some of the original image silver to silver chloride. Cross-contamination by carry-over from the gold or hypo bath will result in yellow stains.

Self-toning Paper With a little gold salt added to the emulsion, the print tones itself to a rich brown while fixing. This is probably due to the formation of what used to be called sel d’or or (erroneously!) gold hyposulphite, and which has the property of toning silver images. Glafkides gives the amount of gold salt (chloride or thiocyanate) as 2.5 g per 100 g of silver nitrate in the emulsion (equals one-fortieth), and this seems to be right. I have not tried thiocyanate, but hydrogen and calcium tetrachloroaurate both work: add 1 ml of a 1% solution to every 10 ml of working emulsion. It becomes orange-brown on adding the gold, but the colour gradually clears as it is stirred in. The emulsion behaves normally during printing, and the gold has no effect until the fixing bath. Prints are fixed WITHOUT prior washing. The colour of the wet print may not appear vastly different to straight emulsion, but the difference is plainly visible if compared with an untoned print. The colour of the image may be varied, becoming cooler as the fixer is used stronger, its temperature higher, or the time of immersion prolonged. A 15% solution of hypo crystals (or roughly 9.5% of anhydrous hypo) gives warm brown tones, while 30% crystalline (19% anh.) produces cold purple-browns. This, at least, is what the books tell us, but in tests I found colour variation by these means almost negligible. It is also said that with self-toning paper the density loss in the fix is much greater, but I do not exactly agree with this either; what I would say is that printing takes a little longer when the emulsion contains gold. But the brown colour may be warmed by adding a pinch of sodium carbonate to the fixer (this does work!) It is, in fact, a good idea to use an alkaline rather than plain hypo solution if the gold salt used is hydrogen tetrachloroaurate because it is acidic and there is less likelihood of it causing sulphur precipitation from an alkaline fixer. A little sulphite offers further protection; the fixer given earlier is, in fact, ideal, with the hypo content varied if desired. The fixing time is 10 minutes in the weak fix, or 5 minutes in the strong; longer times may result in image bleaching. Remember that prints go straight from the printing frame to the fix without prior rinsing, and the fix should be discarded after use (again, there is greater danger of sulphur forming in an overworked fixer). Allow about 50 ml of fix for an area of 8”X10”, and keep it moving over the print. Permanence Ancient POP prints do exist in good condition, but not nearly as many as we might expect given the popularity of POP over a very long period. This raises questions which it is only fair to mention. “Provided that care is given to each stage of the process, and particularly to efficient fixing and washing,” the Ilford Manual tells us, “prints on P.O.P. will last for years under proper conditions.” That sounds ominous! Yet Reilly (The Albumen and Salted Paper Book) states that apart from the difficulties with combined toning and fixing baths, gelatin (and collodion) printing-out papers have “an excellent record of stability”. The heyday of POP being a little before my time, I have no first-hand experience of these matters, but believe, from what I have read, that problems were mainly caused by the presence of sulphur in finished prints. This could arise through the use of exhausted toning-fixing baths, or through the action of acidic gold salts on a well-used fixer (via cross-contamination of separate toner and fixer, or, presumably, the use of old fixer with self-toning papers). My feeling is that fresh solutions, washing well between the different stages of processing, and, particularly, the avoidance of combined toning-fixing baths, will yield satisfactory permanence. Fixer is probably best used one-shot, or if, as suggested, it is reused to modify the imager colour, a fresh fix should follow. The final wash also needs to be very thorough, and the times given earlier should be regarded as the bare minimum in an efficient washer. These precautions, plus the use of alkaline fixer containing a small amount of sulphite, should avoid any danger of sulphur precipitating from the fixer. Anyone sufficiently concerned about the issue of permanence is advised to do some reading for themselves. Reilly is a good place to start. This article was originally published, in a condensed version, in The World Journal of Post-Factory Photography, #5, August 2000. This article is copyright 2000-2005 by Liam Lawless. All rights reserved. Reproduction of this article in any form is prohibited without the express permission of the author.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|