|

MUCH MORE ABOUT STAIN

There are several aspects of stain that need to be considered. They are: 1) intensity and color of the stain, 2) whether the stain is proportional image stain or general

b+f (base plus fog) stain, and how this can be controlled, and 3) what are the differences, if any, between Pyrocat-HD stain and the stain produced by other Pyro developers.

INTENSITY AND COLOR OF THE PYROCAT-HD

STAIN

The stain produced by Pyrocat-HD is typically brown, or even brownish-black. Photographers who have previously used developers like PMK and Rollo Pyro nearly always underestimate the intensity of the Pyrocat-HD

stain because by comparison with the green or greenish/yellow stain of these developers the brown Pyrocat-HD stain looks almost neutral in color. This is not the case, however, and in practice it will be found that the brown

stain of a Pyrocat-HD negative will have an impact on the effective printing density of the negative that is as great or greater than the green and greenish/yellow stain of other Pyro developers.

When printing with

graded silver papers it will be found that the brown stain of Pyrocat-HD filters out more of the blue and blue-green light to which silver papers are sensitive than does the green stain of PMK and Rollo Pyro, the practical

consequence of which is a boost in contrast. And this is even more true when printing with alternative processes based on exposure to UV light because brown is a much more highly actinic filter for UV light than

green.

There appears to be a universal acceptance in some quarters that certain films work better with Pyro developers than others because they stain better. Gordon Hutchings, who developed the PMK formula, promotes this

point of view, as do many other PMK users. My own testing, however, does not support this conclusion. What I have found is that with proportional image stain the amount of stain is much more dependent on the overall

density of the negative than on film type. What I conclude from this is that proportional stain is a stain that exists primarily around silver grains and staining developers work about equally well with all films, since all

films contain silver in sufficient quantity to develop high density levels, even without staining. That some films appear to work better than others is due to fact that the gelatin base of some films is thicker and these films

develop more general stain for the simple reason that there is more gelatin to stain. And this is far from desirable, as we shall discuss in the next section.

DIFFERENCE BETWEEN IMAGE STAIN AND GENERAL

At the

outset it is important to understand that there are really two kinds of stain: image stain, and general or b+f (base plus fog) stain. Image stain is a proportional stain that is formed directly around silver grains. It is

desirable stain because it can greatly increase the micro-contrast of the negative and boost overall printing contrast, which can be very useful with alternative printing processes that require negatives of high-density range.

General stain, on the other hand, affects the entire gelatin layer, regardless of whether there is silver density present or not. It is present everywhere on the film in equal amounts, and for that reason results in unnecessary

fog. You can easily spot it by looking at the clear area of the film. When film is developed in a Pyro developer the general stain should be only slightly greater than when it is developed in a traditional non-staining

developer. If there is a lot of stain in the clear areas of the film it is almost surely general stain. General stain serves no useful function: it increases printing exposure times, and under certain conditions is harmful to

image quality because it can limit the useful CI (contrast index) of films.

General stain is much less of a problem with Pyrocat-HD than with Pyrogallol based developers such as PMK, ABC Pyro and Rollo Pyro. This is due

to the fact that pyrocatechin, the primary reducing agent in Pyrocat-HD, does not oxidize as rapidly in alkaline solutions as pyrogallol. And of course the main cause of excessive general stain is aerial oxidation.

No

special precaution is necessary with Pyrocat-HD to prevent general stain from aerial oxidation when developing film in trays or in tanks, and this is true even when films are subjected to long development times needed to reach

the high CI necessary for printing with alternative processes. However, as mentioned earlier, one should avoid using very fast rotation with rotary processing, especially with thick emulsion films such as Bergger BPF, Kodak

TRI-X, and Ilford HP5+.

STAIN WITH PYROCAT-HD AND OTHER PYRO DEVELOPERS

In comparing the effect of the stain of Pyrocat-HD to that of other developers it is important that we distinguish between the various kinds

of processes being used. As we have already observed, the color of the Pyrocat-HD stain is different from that of other Pyro staining developers. And, since different kinds of papers and processes have a different spectral

response to light it follows that there will be some differences in printing depending on the color of the stain.

Most persons working with Pyro staining developers are printing with one of the following

processes.

1. Graded Silver Gelatin Papers

2. Variable Contrast Silver Gelatin Papers

3.

AZO

4. Alternative processes that need high levels of UV light for exposure.

Let us consider the impact of different stains for each of these processes.

GRADED SILVER GELATIN

PAPES

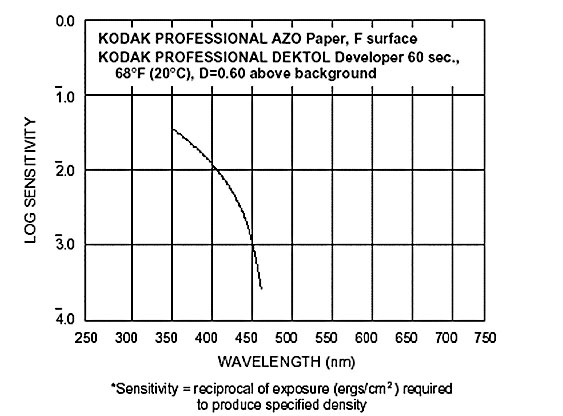

Graded silver papers consist of one layer of emulsion on a paper or RC base. The range of sensitivity for graded papers begins with UV and extends through the visible range of violet, blue, and slightly into the

green. Generally, we use a UV filter when printing to eliminate UV light from the equation. Graded papers are most sensitive to blue light and as a general rule the blue channel of a color densitometer will provide a fairly

accurate indication of the actual printing contrast, or exposure scale, of the paper. In theory this means that the function of the stain with graded silver papers is to boost contrast so that there is little difference or

advantage derived from the color of the stain.

In practice, however, it will be found that the brown stain of Pyrocat-Hd will print with slightly more contrast than the green stain of other Pyro staining developers. This

is due to the fact that graded papers have some sensitivity to green light, and brown stain blocks green light more efficiently than green stain.

VARIABLE CONTRAST SILVER GELATIN PAPERS

Variable contrast silver

papers have two emulsion layers: a blue sensitive high-contrast layer, and a green sensitive low-contrast layer. With these papers the color of the stain is very important and in practice one will get quite different results

when printing with brown stained and green stained negatives.

When printing VC papers with green stained negatives it will be found that the green stain acts as a continuously variable contrast filter that has as its

practical consequence the ability to hold highlight values extremely well. The filter is variable because of the proportional nature of the stain, which is of course greatest in the highlights where there is a lot of silver

density. The negative side of this coin is that extending the luminance range comes at the cost of a loss of contrast in these values. In other words, the higher the luminance values the more shouldering you will see in the

curve of a print made with a green stained negative, and this translates into a flattening, or loss of contrast, in highlight tones. In practice it will be found that the shouldering tendency with green stained negatives

actually begins in the upper mid-tones so that one will see some flattening of tones in these areas as well as in the highlights. If you look at the literature you will see that one of the major objections to PMK has been

the lack of separation, or contrast, in the upper mid-tones and highlight areas.

Brown stain blocks green light more effectively than green stain, and for that reason there is much less shouldering in the highlights with

Pyrocat-HD than with PMK. The result is that prints made with Pyrocat-HD negatives on VC papers will have more contrast in the highlights than prints made with PMK negatives, but there will less compensating

effect.

AZO

AZO paper is similar to regular graded papers in that it has a lot of sensitivity to blue light, but different in that it has much less sensitivity to green light. AZO is much slower than other silver

gelatin papers and must be contact printed. And, while AZO is available in two grades, even the softest grade has a much longer ES (Exposure Scale) than regular silver papers. This means that you need a negative with a lot of

contrast to print with Grade 2 AZO paper. Stained negatives intended for printing with a Grade 2 AZO should have a Visual density reading of approximately log 1.2, which will translate to about log 1.5 with a Blue channel

reading.

In practice it will be found that the brown Pyrocat-HD blocks a lot more of the blue and UV light than the greenish stain of other Pyro developers, which means that for a given Visual density reading a

Pyrocat-HD negative will print AZO with more contrast than either PMK or Rollo Pyro.

So how does Pyrocat-HD compare to ABC Pyro for printing AZO. Very well indeed, and based on recent exchanges on Michael and

Paula’s AZO forum it is clear that quite a number of ABC Pyro users have switched to Pyrocat-HD. I recently made some comparisons of the two developers on the AZO forum, reproduced here in a slightly edited

form.

COMPARISON OF ABC PYRO WITH PYROCAT-HD

1. For negatives intended for printing with AZO or an alternative process such as carbon, kallitype, platinum/palladium one should use the 2:2:100 dilution of

Pyrocat-HD.

2. ABC Pyro, used at the 1:1:1:7 dilution, is slightly more energetic than Pyrocat-HD at the 2:2:100 dilution. This means that development times with Pyrocat-HD will need to be slightly longer than with ABC

Pyro, perhaps about 20-25% or so, to reach the same CI (contrast index).

3. A visual comparison of an ABC Pyro negative and a Pyrocat-HD negative will be misleading because a much higher percentage of the effective

printing density of a Pyrocat-HD negative consists of stain density.

4. Pyrocat-HD negatives are much finer grained than those developed in ABC Pyro, making it a more universal developer since it can also be used with

roll film as well as sheet film for projection printing without the large grain that is characteristic of ABC Pyro.

5. The uneven development and streaking that many people have experienced with pyrogallol based

developers, including both PMK and ABC Pyro, is entirely eliminated with Pyrocat-HD.

6. Pyrocat-HD is a better developer for making dual-purpose negatives for those who are interested in working with both regular silver

papers and AZO (or with alternative process such as carbon, platinum/palladium or kallitype). This is because Pyrocat-HD negatives have a much greater difference between the effective printing density for UV light processes and

blue sensitive light processes than ABC. This results from the fact that a much higher percentage of the effective printing density of a Pyrocat-HD negative consists of brown stain, which functions as a highly effective filter

to UV light.

|

Figure 2. Spectral Sensitivity Chart of AZO Paper, F surface.

ALTERNATIVE PROCESSES

Printing with alternative processes such as albumen, carbon, kallitype, platinum/palladium, salted paper, and vandyke is similar to printing with AZO in that these processes require

negatives of high DR (density range), ranging from a low of about log 1.4 with platinum to a high of over log 2.25 with albumen and salted paper. Alternative processes are most sensitive to

UV light, and since the stain of Pyro developers functions as a highly actinic filter to UV light it follows that the stain can add a lot of effective printing contrast to a negative. As an actinic filter

for UV light the brown stain of Pyrocat-HD is much more efficient than the greenish stain of some of the other staining developers.

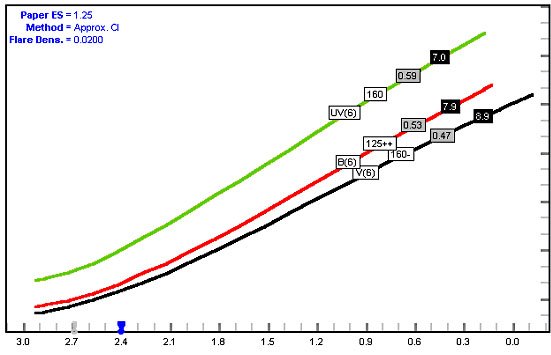

I have compared the Visual, Blue and UV curves of Ilford FP4+ with several Pyro developers and have reproduced the curves below. The developers compared were: 1) Pyrocat-HD,

2:2:100, 2) PMK, 1:2:100, 3) Rollo Pyro, 2:4:100, 4) WD2D, 20:20:400, and 5) Pyrocat-HD, 1:1:100

|

|

Figure 3. Ilford FP4+ in Pyrocat 2:2:100.

Film developed for six minutes at 70 degree F, in BTZS types tubes. Black curve is Visual

Reading, Red Curve is Blue Reading, and Green Curve is UV reading.

|

|

|

Figure 4. Ilford FP4+ in PMK 1:2:100.

Film developed for 20 minutes at 70 degree F, in BTZS types tubes. Black curve is Visual

Reading, Red Curve is Blue Reading, and Green Curve is UV reading.

|

|

|

Figure 5. Ilford FP4+ in Wimberley WD2D+, 20:20:400.

Film developed for 15 minutes at 70 degree F, in BTZS types tubes. Black curve

is Visual Reading, Red Curve is Blue Reading, and Green Curve is UV reading.

|

|

|

Figure 6. Ilford FP4+ in Rollo Pyro 2:4:100.

Film developed for 6 minutes at 70 degree F, in BTZS types tubes. Black curve is

Visual Reading, Red Curve is Blue Reading, and Green Curve is UV reading.

|

|

|

Figure 7. Ilford FP4+ in Pyrocat 1:1:100.

Film developed for 10 minutes at 70 degree F, in BTZS types tubes. Black curve is

Visual Reading, Red Curve is Blue Reading, and Green Curve is UV reading.

|

|

Development of all of the above negatives was in BTZS type tubes in a water-bath. The CI of all of the curves has been normalized for the UV reading for a SBR of 7, equivalent to N

development in Zone speak.

Analysis of the curves reveals some interesting information.

1. The density range that results from developing for a SBR of 7.0 ranges from about log 1.2 to log 1.3.

2. Even for a relatively low DR of 1.2 to 1.3, PMK and WD2D require fairly long development times, 20 minutes and 15 minutes respectively. This fact makes these developers only

marginally useful for alternative processes in normal SBR conditions, and quite impractical for use with negatives exposed in scenes requiring N+ development.

3. Pyrocat-HD at the 1:1:100 produces the highest effective film speed with the FP4+ emulsion. At ten minutes of development for a SBR of 7, the effective film speed of FP4+ is EI 200. All of

the other combinations produce a maximum EI of 160 with the same parameters.

4. Pyrocat-HD at the 2:2:100 dilution and Rollo Pyro at the 2:4:100 dilution produce almost

identical curves in the UV at six minutes of development.

5. The Pyrocat-HD negatives have a greater difference between the UV and Blue reading than

the other developers. This is a fact of some consequence because it clearly shows that Pyrocat-HD would make a much better developer for dual-purpose negatives than any of the other

developers. That is, a Pyrocat-HD negative that would print well with regular silver gelatin papers (which are most sensitive to blue light), would also print well with an alternative

process sensitive to UV light. By contrast the greenish stain of the pyrogallol-based developers is much less effective as an actinic filter to UV light, the result being that the stain adds very

little additional effective print density to the negative with UV sensitive processes.

|